EXPERT INSIGHT

5 Ways to Maintain AM Productivity during COVID-19 Pandemic

To say COVID-19 has made a significant impact worldwide is an understatement. Schools are closed, events are canceled, and governments are asking employees to work from home whenever possible. In order to stay healthy and refrain from spreading the coronavirus further, many are working from home and practicing social distancing.

For those in additive manufacturing, sophisticated AM software is a key solution for seamlessly transitioning to working remotely and minimizing in-person communication during the COVID-19 pandemic. In addition to flexible remote working solutions and free tools you can obtain online, many AM software options support working from a distance with various digital features. Here are five ways to keep up productivity with the help of 3D printing software.

1. Take advantage of flexible software licenses

For companies in the position to provide employees with the opportunity to work remotely, it’s essential to transfer access to the necessary tools and software to additional computers and networks. Many people are not accustomed to working outside of the office, but with the appropriate tools, such as flexible licenses, organizations can minimize disruption to their business activity.

To help other businesses during this time, Materialise, is extending free, flexible licenses to customers with maintenance packages so that they can continue their typical workflow. With flexible licenses, users can seamlessly transfer their work to home offices and ensure continuity.

2. Access free software

Smooth communication between customers and sales is crucial in order to print successfully and maintain workflows. However, these conversations can no longer be held face-to-face. Seamlessly continue back-and-forth communication with your customers with the help of free software that shares an overview of parts during the data preparation phase.

With free software such as MiniMagics, even customers without Magics can view STL files on their own devices. Thanks to the compatibility between Magics and MiniMagics, they can share comments, take measurements, and get an overview of common 3D printing errors such as bad edges, flipped triangles, and multiple shells. In-person communication may not be possible, but with free software, we can continue having these conversations successfully.

You can even share files with customers without access to AM software. Export files to 3D PDF, and, although it offers fewer features than MiniMagics, customers can still examine designs, view wall thickness analyses, and add comments via a 3D PDF viewer.

3. Communicate within software

Along with free and flexible solutions that are optimal for times such as this when remote working is necessary, there are additional steps you can take using your AM software to reduce contact with others. To improve communication with customers and colleagues, try sharing your ideas and comments on digital platforms such as your AM software.

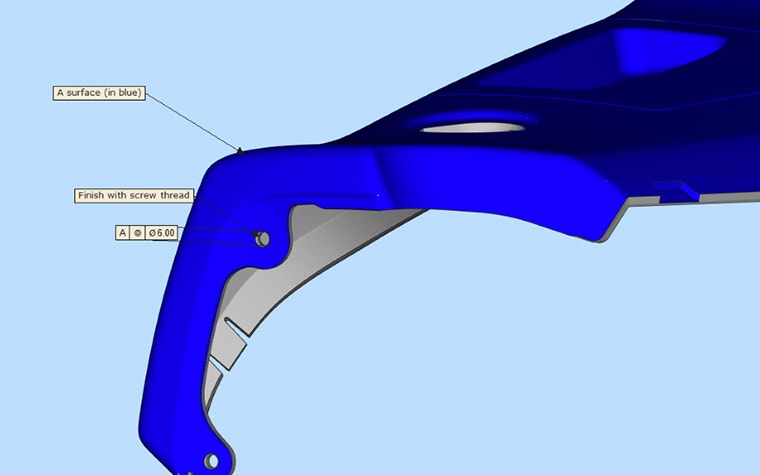

For example, within Magics users can write and share clear annotations that appear alongside parts for others to see when they use Magics or MiniMagics. To help add clarity, you can also color certain sections of the design to highlight specific areas that you are referring to, such as if you would like to tell others which is the A surface.

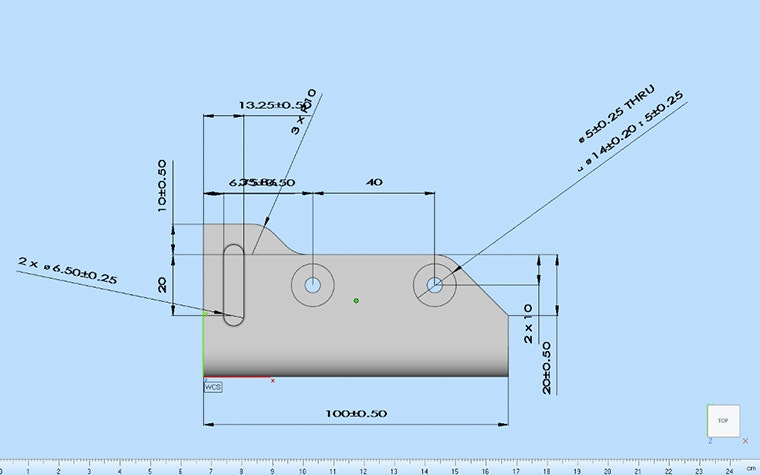

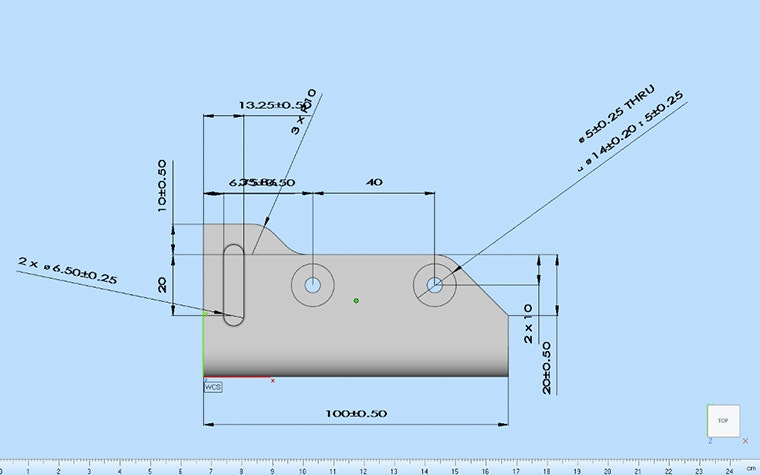

You can simplify communication within your own team as well with Magics. By importing the product and manufacturing information (PMI) from your CAD file directly into Magics, distances, measurements, and error margins are visible to both designers and production. With this data, machine operators can validate whether a part’s measurements are within acceptable margins without the need to speak directly to designers.

4. Share reports digitally

Thanks to the ability to create digital reports with Magics, data preppers can extract part parameters to share with production managers via online communication methods. With reporting tools, machine operators gain insights into the details of parts within a build, including viewing measurements and the number of slices, without the need to speak directly with others.

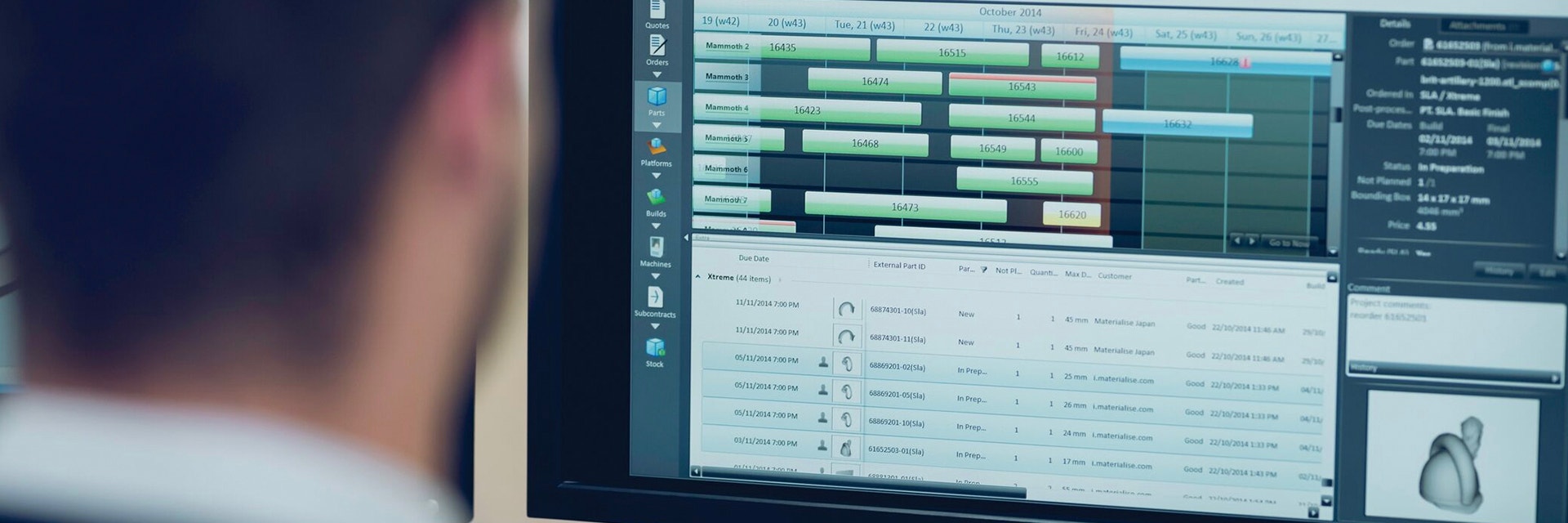

Accessing this data via digital reports allows machine operators to see what is being printed and what they will need to load off once the printing process is complete. Streamics, our production management software, also provides production managers with the ability to track parts and send failed prints back to the beginning of the process with the click of a button.

5. See a clear overview of production

Sharing information digitally helps us minimize the need for human contact, even when the people you’re communicating with are in the same production facility as you. Maintaining a clear overview of how production is running is another instance in which production management software can assist at this time.

With the help of software like Streamics, you can send builds straight to machines and monitor their statuses. Gain insight into the progress of your printers and optimize the use of every machine using this data. This software not only reduces the need for contact with others, it also reduces the time needed to check the status of all of your printers: it’s a win-win.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.