CASE STUDY

No More Pancake Waste! How AM Transformed Bakery Production Lines of a Favorite Food

How are your favorite pancakes made? Lines of batter in circles, baking on one side before they’re flipped to the other side and can become perfectly browned. Kaak Group works on designing, manufacturing, and installing bakery lines like this every day, with the support of K3D’s metal 3D printing expertise.

When they were faced with the challenge of improving pancake baking lines that resulted in too much waste, K3D turned to Materialise software and Additive Industries hardware to fully leverage the power of 3D printing.

Challenge

Baking pancakes can be a messy business. K3D discovered this challenge when pancake lifters used to make 20,000 pancakes per hour needed to be optimized. The traditional design used in these lines faced issues with waste. The pancake-making process began as pancake batter was baked on a large plate in an industrial oven. But upon removing the pancakes from the baking plate, the lifting device would regularly get clogged up with the sticky batter.

This issue in the line led to a few other bumps in the road. Firstly, it resulted in major product waste. Any pancakes that stuck to the lifter would no longer meet the quality requirements and therefore would need to be removed.

Secondly, all the waste build-up caused postponements in the production line. The stuck batter dirtied the machines, resulting in teams stopping the entire line to clean them. The delays and excess waste meant that this process needed a serious boost in efficiency.

Kaak Group tried attempted many solutions, but none of them worked due to issues such as meeting food safety regulations. However, K3D knew that metal 3D printing had the exact capabilities needed to achieve the production goal. So they combined their extensive knowledge of 3D printing with robust software and industrial 3D printers and got started. This dependable trio was necessary to deliver an improved solution at scale — both for retrofitting existing lines and adding new installations.

Solution

The first component crucial to this case was K3D’s own knowledge of metal 3D printing and food-safe additive manufacturing (AM) materials. Thanks to the team’s expertise, they knew that AM had the design and manufacturing capabilities necessary to improve this part and print it with speed.

“We began the project by optimizing the printing parameters of solid and porose parts through the design of experiment (DOE) methodology. This could not happen without the open system that Additive Industries provides,” explains Jaap Bulsink, CTO at K3D. This involves running a set of experiments on small cubes to determine which parameters are ideal to print this part. “Materialise Build Processor for Additive Industries played a major role in this step. Because it’s designed specifically to work alongside our MetalFab1, setting up printing parameters for each experiment was a breeze.”

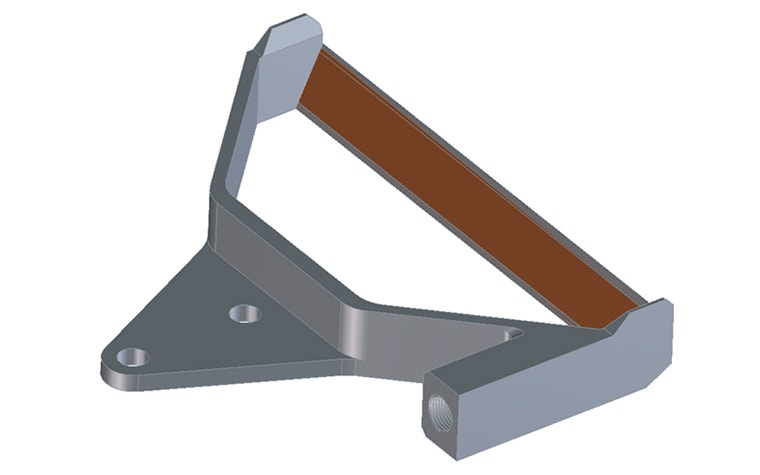

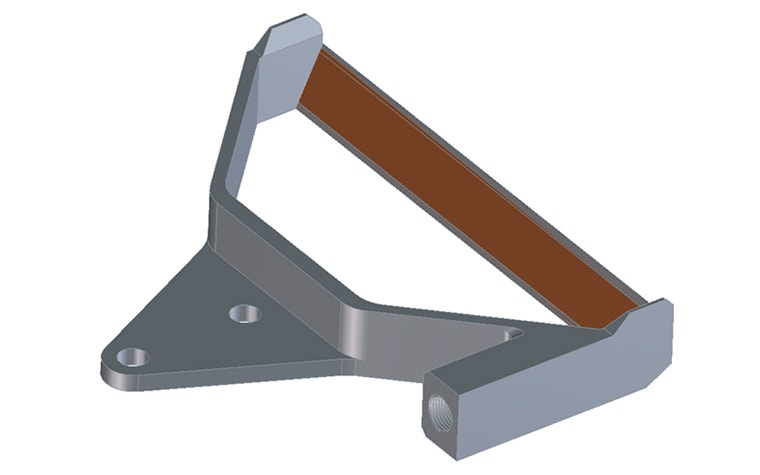

Once they determined the material and finalized the printing parameters, the K3D team got to work redesigning the part. Here, they placed a focus not only on improving the part’s performance but also on integrated functionality to ensure that they could print the part in just one piece. To prepare this new design for printing, the team used Materialise Magics and its modules.

“Magics enables us to quickly prepare our design to be printed,” shares Jaap. “It offers all of the features we need in any easy-to-use set-up. We especially appreciate the SG+ module. This tool automatically generates supports specifically for metal parts, including internal sections. The thin, optimized support geometry was crucial for this design because the integrated internal channel needed airflow to get through the support. This proved no problem at all with SG+.”

Finally came the printing of the parts. For this, they used the MetalFAB1 printer from Additive Industries. “We are producing a lot of metal parts for different markets on an industrial level and the MetalFAB1 printer is the perfect machine to fulfill this because of its automation and ease of use,” says Bob Van Lochem, Lead Operator at K3D.

“The machine features automated processes which qualify and calibrate four full-field lasers, ensuring repeatable quality,” explains Jurgen Westerhoff, Product Manager at Additive Industries. “For industrial printing like this, you also need robust software. That’s why we bundle our machines with Materialise software - including Magics and Build Processor — to ensure a seamless workflow for users.”

Result

After completing the process of determining the optimal parameters and redesigning the part, the K3D had a 3D-printed design to combat the stickiness experienced in the production line. The new design is one complete part featuring internal channels and porous metal parts that allow airflow. This air is pushed into the lifter and blows out of its pores. The pancakes can then hover above the lifter, much like a hovercraft over water.

But it doesn’t end there. This application serves as an excellent benchmark for other production lines and industries that aim to overcome contamination and stickiness via contactless manipulation of parts. Beyond the food industry, the design could also be ideal for automotive, healthcare, and more.

The team also used this redesign to reduce the amount of material needed. 3D printing allows for integrated, organic forms that, with the right know-how behind them, mean improvements such as this can be made. Less material benefited the project in multiple ways, including reducing material costs and accelerating machine build time.

“Now, each production line is seeing a reduction in pancake waste by thousands of kilograms as well as a 10% increase in productivity.”

— Jaap Bulsink, CTO, K3D

Thanks to the new design and reduction in pancake waste, the related issues were also resolved. Productions saw fewer rejected pancakes and less downtime in the production line to clean the machines. “Now, each production line is seeing a reduction in pancake waste by thousands of kilograms as well as a 10% increase in productivity,” concludes Jaap. “That’s savings of €85,000 per year by improving just one element of the process. Just imagine how much more we can achieve with 3D printing.”

Share on:

This case study in a few words

Bakery technology

Consumer goods

Metal 3D printing

3D printing software

Minimizing pancake waste along a bakery production line

How we helped

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Slice and send jobs to 3D printers based on machine-specific strategies or optimize custom scan path strategies with our software development kit.