INTERVIEW

“Long-Term Vision and Adaptability”: Belgian Federal Mobility Policy Chief on Her Visit to Materialise

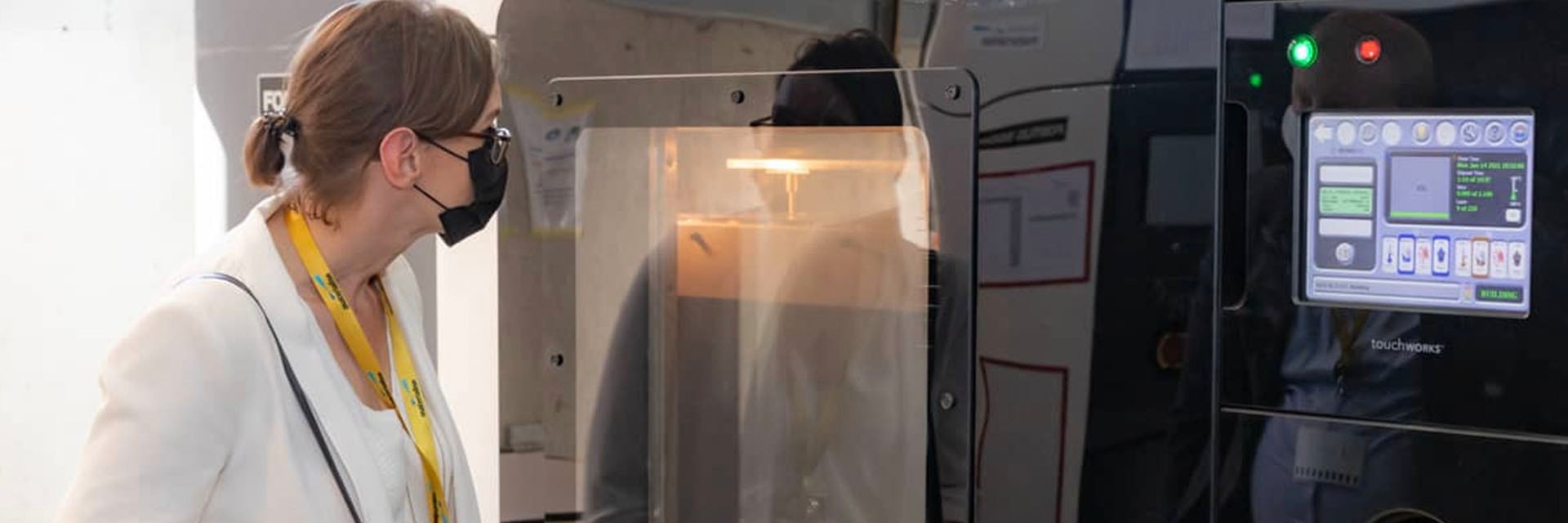

Materialise has a long track record as a manufacturer for highly regulated industries, such as aerospace. Six years after achieving the accreditation to manufacture end-use parts for aircraft, Materialise now produces over 26,000 parts per year for the Airbus A350 system alone. In recognition of this achievement, and more broadly the growing maturity of additive manufacturing in the aerospace sector, we recently hosted a special visit.

The Federal Public Service (FPS) Mobility and Transport is Belgium’s leading policymaking body for transportation. Emmanuelle Vandamme has led the FPS since 2019, serving as the president of its management committee. As part of their initiative to visit companies subject to mandatory audits by the department and those they see as innovating in the field, we welcomed Ms. Vandamme and her team at Materialise for a glimpse behind the scenes at our additive manufacturing facilities.

Welcome to Materialise, Ms. Vandamme. Please tell us a bit about yourself; your main work mission at the FPS Mobility, the goals and challenges you deal with every day.

I’ve been working in the public sector for 20 years. My interests center around innovation in two areas: working processes and human resources on the one hand, and technological innovation on the other. Mobility is a dynamic sector that combines both these areas nicely. I took my current position as the president of the FPS Mobility and Transport in 2019. The department has a wide mandate, we cover road traffic as well as aviation, shipping, and railway transport. My focus there is on ensuring safety and security for end users.

How do you usually tackle that mission of ensuring safety? Have your methods had to change because of the COVID crisis?

Absolutely. The most conventional tool we have is auditing, and of course that was heavily impacted by the new working conditions since COVID. Like everyone else, we faced the challenge to digitalize quickly, albeit that we had already made significant strides in that regard as a majority of our civil servants work one or two days a week from home. But it is a difficult balance. We work hard to support our teams to do audits virtually, but a thorough inspection needs some level of physical presence on the ground. There we have had to strike the balance between enabling field work and ensuring our people’s safety.

Besides, the role of an auditor is traditionally quite a reactive one. Implementing correct processes is a continuous effort, and we want to be more proactive in supporting the industry to do this. That’s why we have been working a lot on close collaboration with relevant organizations over the past two years, particularly in the aviation and maritime sectors.

Like today’s visit to Materialise! What are your thoughts on the state of 3D printing today, and Materialise’s approach to aerospace manufacturing in particular?

When we took the tour of the 3D printing facilities just now, my first thought was, “Unbelievable!” I’m impressed by the long-term vision and adaptability that Materialise is showing in the face of changing industry needs.

New technology also needs a different approach to regulation. When it comes to technologies such as 3D printing, it’s essential for us to properly equip our teams of auditors. Not only with information but by cultivating an interest and even a passion in the technology, so that they are able to conduct thorough inspections. Partnerships with companies like Materialise are key here.

Our goal, again, is to change the role of an auditor from a reactive position to a more proactive one. Audits are like the end-of-year exam: if you’ve been doing your assignments properly all year, then the final exam result shouldn’t be a surprise. That’s why we cultivate partnerships within the industry, and build closer communication channels, because we want to ensure companies like Materialise have the leeway to innovate, without compensating on our main mission goals: safety and security in the transport sector.

Which innovations and trends in the mobility sector are you most excited about?

You see a number of initiatives that have sustainability at their heart. We recently ran a webinar on mobility as a service (MaaS), for example, which is gaining wider recognition as one of the solutions for sustainable, accessible mobility. Generally speaking, the tech sector advances much faster than policy. That’s our key challenge, finding the equilibrium where we support innovation and work within policy frameworks such as the Green Deal. At the FPS we see ourselves as a facilitator; we create public-private partnerships and have a dedicated research service to support innovation. In the end, it’s all about strong collaboration between industry and policy.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.