COMPANY HIGHLIGHTS

MAKING A DIFFERENCE / A DIFFERENCE IN MAKING Opens April 24th at BOZAR Centre for Fine Arts

February 25, 2015

What is so novel about 3D Printing anyway? And what impact does 3D Printing have on individual lives? What about society? And even larger, the environment? All these questions will be explored at MAKING A DIFFERENCE / A DIFFERENCE IN MAKING, from April 24th to June 7th at the internationally-renowned BOZAR Centre for Fine Arts in Brussels. Materialise has been working with curator Marta Malé-Alemany to put together this exhibition that looks at 3D Printing with both the eyes of fascination and a deeper observation of its consequences.

As you can probably guess from the title, the exhibition will be split up into two main sections. One will show how 3D Printing is “a difference in making” by showing designs that experiment with this technology. Specifically, how 3D Printing can make complex forms, use new materials, and create scaffolds that support natural processes such as petrification or organic growth, like these pieces:

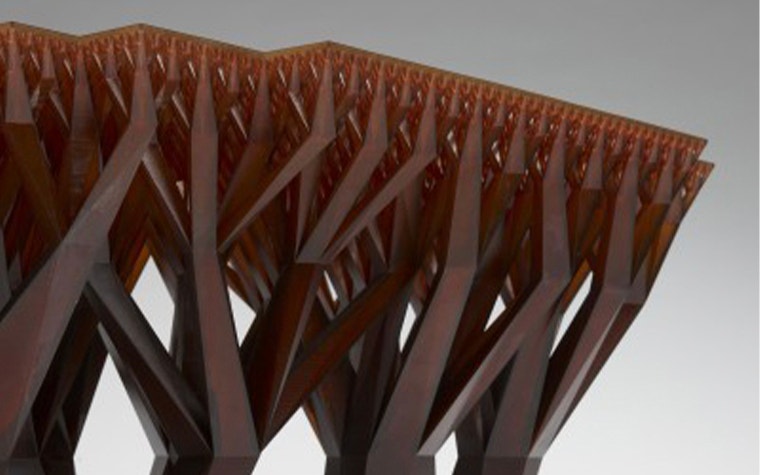

FRACTAL.MGX / WertelOberfell with Matthias Bär

Name of the artwork/product: Fractal.MGX

Year: 2008

Company: WertelOberfell - Platform

Designers: Jan Wertel, Gernot Oberfell with Matthias Bär

Manufacturer: Materialise

Photo credits: Stéphane Briolant Paris

The FRACTAL.MGX table has become an iconic piece of furniture that in essence explores the potential of 3D Printing in design. The table consists of a series of arborescent legs, which bifurcate repeatedly as they reach the tabletop, following the fractal growth pattern of trees. The overall design reaches a formal complexity that is impossible to produce by other methods than 3D Printing.

ONE_SHOT.MGX / Patrick Jouin

Name of the artwork/product: One_Shot.MGX

Year: 2006

Company: Patrick Jouin

Designer: Patrick Jouin

Manufacturer: Materialise

Photo credits: Thomas Duval

ONE_SHOT.MGX is one of the first applications of 3D Printing for furniture design in the history of this technology. Its groundbreaking concept is still relevant today, because it explores how 3D Printing can be used to manufacture entire assemblies of parts in one go, a unique characteristic of this technology. The stool is printed as a complete object with all its hinges, allowing it to twist and acquire its final form as soon as it comes out of the printer.

ESCAPISM DRESS / Iris van Herpen in collaboration with Daniel Widrig and Materialise

Name of the artwork/product: ESCAPISM Dress

Year: 2011

Company: Iris Van Herpen

Designers: Iris Van Herpen in collaboration with Daniel Widrig & Materialise

Manufacturer: Materialise

Photo credits: Michel Zoeter

Iris Van Herpen is known for her designs, and also for bringing 3D Printing into the world of high fashion. The ESCAPISM dress, designed in collaboration with Daniel Widrig and Materialise, explores the use of highly intricate geometries around the female body, creating an exuberant and unique garment that has been recognized worldwide.

CaCO3 STONEWARE / Laura Lynn Jansen and Thomas Vailly

Name of the artwork/product: CaCO3 Stoneware

Year: 2014

Company: /

Designers: Laura Lynn Jansen & Thomas Vailly

Manufacturer: /

Photo credits: Floor Knaapen

The CaCO3 stoneware highlights one of the most experimental and multi-disciplinary approaches for using 3D Printing in design today. That is: as an auxiliary medium for natural processes, where a minimal 3D-printed scaffold becomes the supporting structure for petrification or other growth and cultivation phenomenon.

The other section is called “making a difference” and looks at just that: how 3D Printing is making a difference in terms of:

The Environment:

How 3D Printing can save material and energy resources and itself be more sustainable and environmentally responsible.

FIX3D BIKE FRAME / James Novak

Name of the artwork/product: FIX3D

Year: 2014

Company: Griffith University

Designer: James Novak

Manufacturer: Materialise (i.materialise)

Photo credits: James Novak

The FIX3D bike frame is a one-off, custom-made piece of sports equipment, exemplary for its minimal design and striking absence of material. It is designed using lattice structures to make it lighter and stronger than traditional bike frames, and manufactured in one piece using 3D Printing. The bike evokes the critical role of 3D Printing for saving energy and resources in the future of mobility.

TI-JOIN CHAIR / Peter Donders

Name of the artwork/product: TI-JOIN Chair

Year: 2012

Company: –

Designer: Peter Donders

Manufacturer: Dentinno

Photo credits: Peter Donders

The TI-JOIN is a hybrid chair, resulting from the assembly of 3D-printed metal joints and carbon fiber tubes. Following principles of lightweight design, the joints provide rigidity and structural strength with a minimal amount of material. 3D Printing is thus applied where it can be of most service, helping to reduce production costs and indirectly benefit the environment.

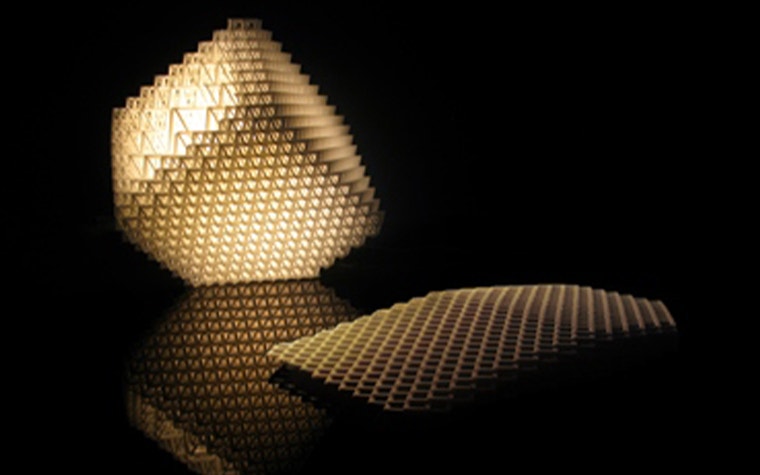

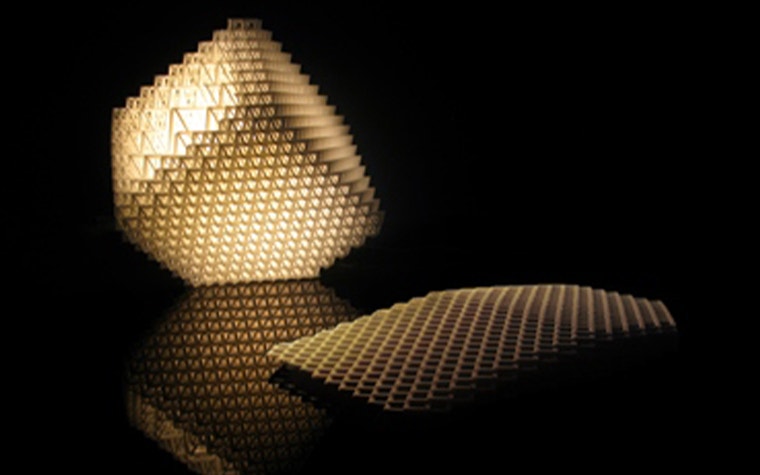

VOLUME.MGX / Dror Benshetrit

Name of the artwork/product: Volume.MGX

Year: 2009

Company: Dror

Designer: Dror Benshetrit

Manufacturer: Materialise

Photo credits: .MGX by Materialise

The VOLUME.MGX lamp shows how a 3D-printed product can be conceptualized and manufactured by paying attention to reducing material and energy costs. The lamp consists of a series of articulated parts, which are collapsed and printed within a minimal volume of nylon powder, thus reducing material and machine time. After printing, the lamp can be unfolded and expanded to its complete volume.

Individual Lives:

How customized objects and parts use personal data to provide individual solutions to unique cases.

SKULL

Name of the artwork/product: Skull implant

Year: 2010

Company: OBL a Materialise Company

Software: 3-matic®

Manufacturer: Polyshape

Photo credits: Materialise

With the advent of 3D scanning tools and 3D Printing, custom medical implants became a reality that is due to transform the lives of many individuals. Today, a patient’s anatomical data can be used to generate a 3D body model, to design a custom implant and print it in titanium. Beyond its perfect fit, this skull implant is designed with a porous, intricate three-dimensional microstructure that facilitates natural bone growth.

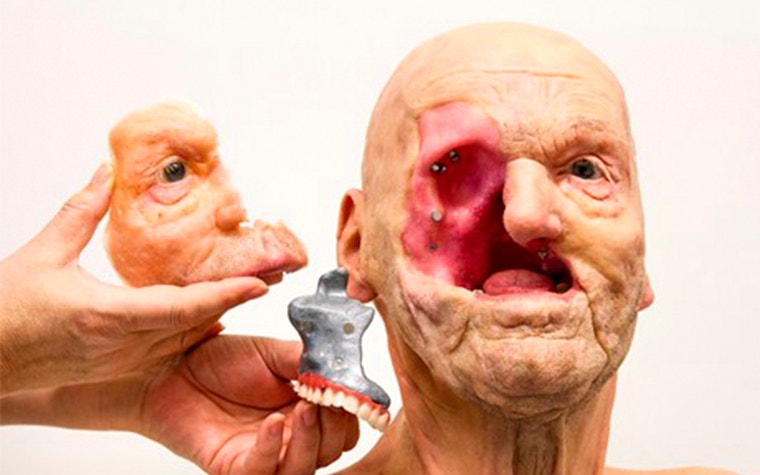

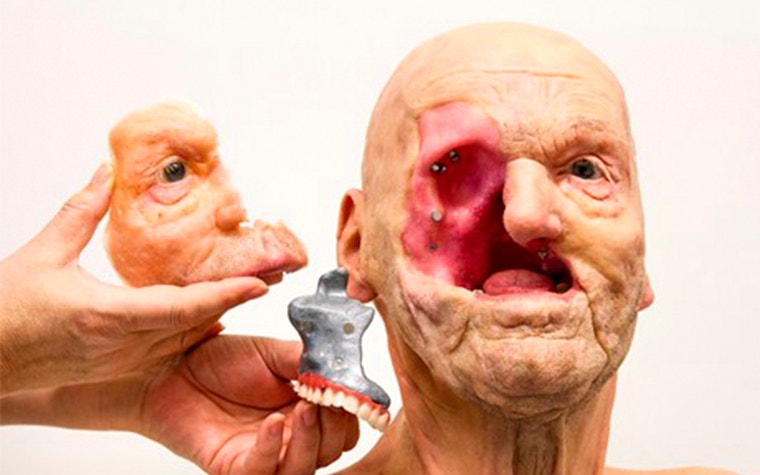

ANAPLASTOLOGY MODEL

Name of the artwork/product: Anaplastology case (model)

Year: 2013

Software: 3-matic® and Mimics® Innovation Suite

Silicon Model: Belgian anaplastologist Jan De Cubber

Manufacturer: Materialise

Photo credits: Materialise

Together with advancements in medical imaging, specialized software and 3D printing equipment are making a difference to individuals by providing customized medical solutions. For a patient who suffered facial cancer, this anaplastology case shows a 3D-printed attachment part in titanium, used to support a 3D-printed silicon prosthesis on the patient’s face.

HEARING AIDS / Phonak

Name of the artwork/product: Hearing Aids

Year: 2000

Company: Phonak

Software: Rapid Shell Modeling Software

Manufacturer: Phonak

Photo credits: Phonak

Hearing aids are one of the best examples to show how 3D Printing is positively affecting the lives of individuals, by providing mass-customized medical care: nowadays, 90% of the devices that are produced worldwide are customized to fit the shape of an individual’s ears, and fabricated at a competitive market price using 3D Printing.

Society:

How 3D Printing can be used to conserve our past and future heritage and revitalize lost crafts.

This section also looks at its implications as a critical instrument of emancipation and social empowerment and how it can improve education.

HELIX TRIPOD / Giambattista Piranesi

Name of the artwork/product: Helix Tripod

Year: 2010

Company: Factum Arte and Fondazioni Giorgio Cini Onlus

Designer: A Factum Arte performance of a design of Giambattista Piranesi

Manufacturer: Factum Arte

Photo credits: Factum Arte and Fondazione Giorgio Cini Onlus

The HELIX TRIPOD is an object that never existed before; it was first 3D modeled on a computer in 2010, based on old sketches by Piranesi. Using the tripod’s virtual data, 3D Printing enabled the conservation and expansion of Piranesi’s cultural heritage: it allowed for the creation of an object from his imagination, centuries after his death.

098XYZ SHOE / Earl Stewart

Name of the artwork/product: 098XYZ

Year: 2013

Company: –

Designer: Earl Stewart

Photo credits: Earl Stewart

The 098XYZ shoe is an example of hybridization between 3D printing technology and traditional shoe making. It illustrates how the most advanced processes of fabrication can be integrated with (and contribute to the revival of) well-established crafts.

SCREW IT DOG / David Graas

Name of the artwork/product: Screw It Dog

Year: 2013

Company: Studio David Graas

Designer: David Graas

Manufacturer: Layers

Photo credits: Tim Smet

SCREW IT is a collection of small 3D-printed objects that are specifically designed to assemble industrial products in a creative way, giving them a new meaning and functionality. SCREW IT demonstrates how 3D Printing is a means to repurpose everyday objects and give them a second life.Will we see you in Brussels this spring? Learn more about this exhibition at www.a-difference-in-making.com, and check out the BOZAR page to learn more about this fine arts center.

This exhibition coincides with the 25th anniversary year of Materialise. Another way that we'll celebrate is through the Materialise World Conference from April 23-25 in Brussels and Leuven. Join us there to share ideas of how to create meaningful innovations through 3D Printing.

Share on: