COMPANY HIGHLIGHTS

How a 3D Printer Is Making a Difference to a Greek Refugee Camp

March 27, 2019

In big cities around the world, you’ll find maker spaces with 3D printers. Popularly called ‘fab labs’ (fabrication laboratories), these are community-built spaces where tools are available for anyone to learn and practice the art and science of making. But take a closer look at this particular maker space. Unlike the usual fab labs in global metropolises, this maker space with its very own 3D printer is near a refugee camp in Greece.

This is the story of Habibi.works, a maker space built to improve the everyday lives of thousands of refugees in Katsikas.

A very special maker space

Habibi.works was set up by the German NGO Soup & Socks eV to support the approximately 3000 people in the neighboring refugee camps, and also the local Greek community in Katsikas. The makers there have free access to well-equipped working areas: a wood workshop, a metal workshop, a sewing atelier and a Media Lab with access to advanced technology such as 3D printing and laser cutting.

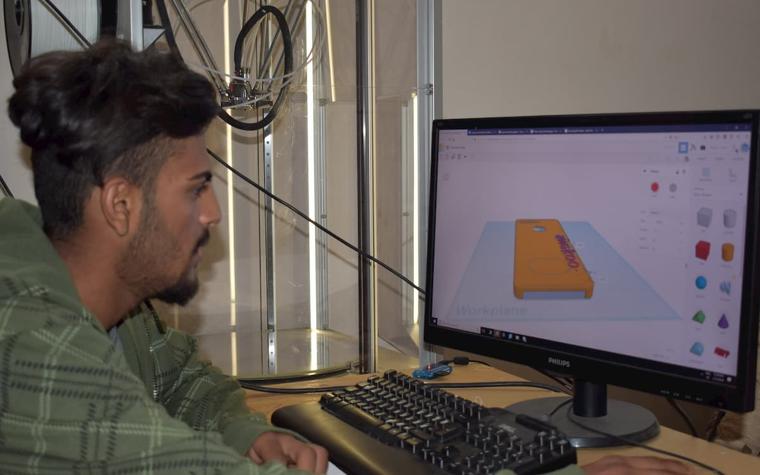

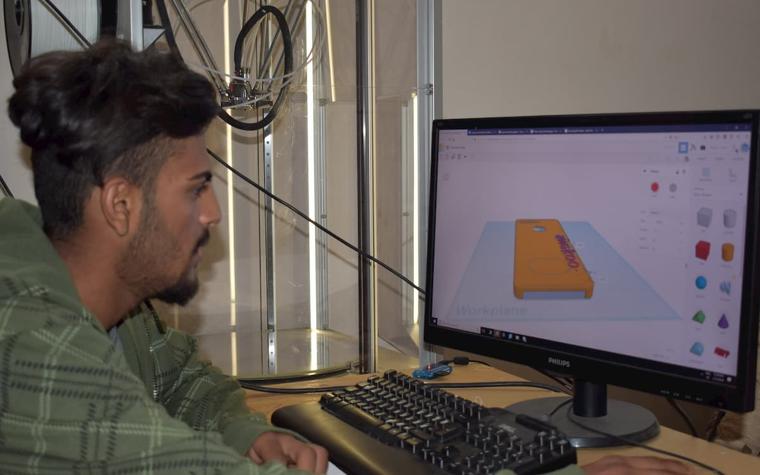

Saad Abouchadi, who has been volunteering with Habibi.works for a year, oversees the 3D printer and the media lab at the maker space. He provides computer classes, facilitates the use of the workshops and teaches makers to use the 3D printer and design software. As Saad puts it, the act of becoming a maker is empowering.

“This space offers new opportunities to the caring individuals, brilliant minds and hardworking hands who live in this camp. Creating solutions instead of waiting for solutions has an incomparable impact on people’s living situation, motivation and self-confidence.”

— Saad Abouchadi, Habibi.works volunteer

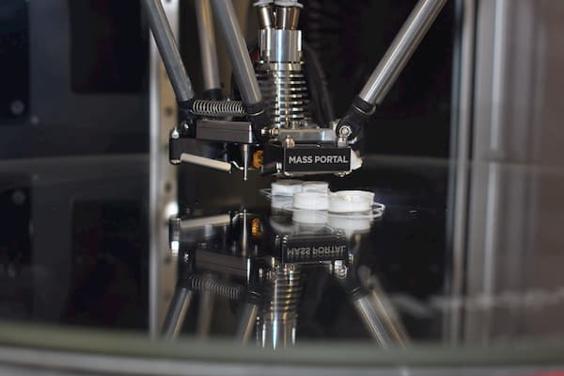

3D printing to improve lives

One of the highlights of the workshop in Katsikas is the new 3D printer, a Mass Portal machine, donated by Materialise. “This is an upgrade on our previous machine as it allows for double extrusion, and creates much more accurate prints,” says Saad.

Just like the other workshops in the maker space at Habibi.works, people contribute their own ideas for what they would like to produce with the 3D printer and approach volunteers to see how to realize their visions. The volunteers and makers think together to choose the best production approach: whether it’s 3D printing, laser cutting, or even the wood workshop. After that, the volunteers guide the new users through the process of 3D design and printing until the project is complete.

Since the arrival of the 3D printer, the makers have designed and printed objects ranging all the way from practical to fun: phone stands, a chess set, mini airplanes for kids and even some 3D-printed jewellery. Thanks to the machine, many people have discovered how to 3D model, got into the design process and built on their existing skills.

Finding solutions together

“One of our strongest values in Habibi.works is that we work with people to find solutions to their problems. It is a two-way interaction. So, people will come to us either with a problem they are trying to solve or with a solution they want to implement, and we will provide the tools and platform to allow them to carry it out. Even when we provide expert workshops or trainings it usually comes from the communities’ interests,” comments Saad.

Through this collaborative approach, the project is not only helping improve people’s living situation through the items they build but also opening the door to a new educational and vocational interest where makers can explore their potential. Saad has already noted positive effects on the community’s motivation and collective spirit.

Equally significantly, spaces like Habibi.works serve to create awareness about both the situation and the talents of the people in their community. When Soup & Socks eV first arrived in the Katsikas camps in March 2016 to set up a community kitchen, the infrastructure was poor, says Saad. There was no running water, no sewage and just 16 chemical toilets for 1200 people. Fast forward to today, and the camp has access to several workshops including the 3D printing fab lab.

The space offers new opportunities to the refugees Habibi.works creates awareness about the situation and talents of the community

“The infrastructure has improved a lot, people are no longer living in tents but in containers with individual bathrooms and kitchens. Still, they are forced to live in this hostile ghetto, excluded from the Greek society, the labour market and in many cases also from education,” explains Saad. “There is still a lot of work to do to improve the situation of the thousands of people who are looking for a better life in Europe. 3D printing in the maker space is just a small step towards a better life, and it’s a way for people to occupy themselves with accomplishment and learning.”

Read more about Habibi.works and the Soups and Socks Foundation. Donations will enable them to buy filament for the 3D printing machine and turn more ideas into reality.

Sustainability is more than just a word for Materialise, it’s a pledge. Our mission to make the world a better and healthier place has been a defining factor of our company since the beginning. Our donation to Habibi.works is part of Materialise’s broader Corporate Social Responsibility program, a key part of which involves supporting non-profit initiatives that use technology to empower people and improve their lives.

Share on: