Webinar

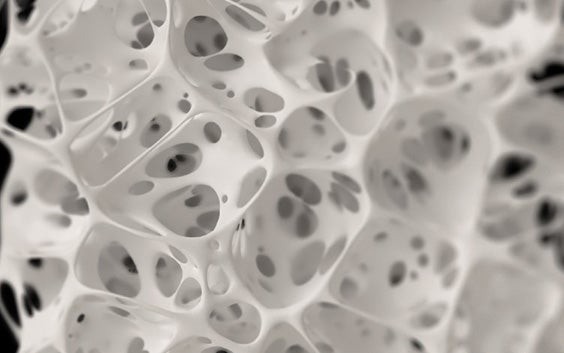

The Critical Role of 3D Printing in Hip Treatment: How Skeletal Stem Cells Can Augment the Outcome

About this webinar

Up to 27% of hip revisions are re-revisions due to a suboptimal fixation and suboptimal biomechanical reconstruction of the joint when combining standard components. Hip re-revisions are even three times more likely to fail compared to a primary acetabular revision. Prof. Douglas Dunlop, Consultant Orthopaedic Surgeon at Southampton University Hospital, shows hands-on examples that trigger a custom-made hip implant like Materialise aMace. Moreover, he comments on the very first case series report focusing on the application of 3D-printed, patient-specific implants that have been augmented with autologous skeletal stem cells.

What you will learn

- Why Prof. Dunlop believes additive manufacturing (3D printing) offers a significant opportunity for orthopaedic practice, bone tissue engineering, and regenerative medicine

- The benefits of combining accurate clinical diagnostics with template planning and custom-made implants, including hands-on examples and testimonials

- The very first case series study focusing on 11 patients treated with complex hip replacement surgery involving 3D-printed implants with SSCs seeded onto the implant surface to restore the anatomy and improve the skeletal biology

- How to significantly improve the Oxford Hip Score (OHS) between preoperative and post-operative scores of 11 patients that underwent hip revision surgery

- Case study of a 72-year-old patient with painful loosening of left THR acetabular component following a complex history of revisions for recurrent aseptic loosening who, after surgery, benefits from extensive (grade 3) new bone formation at the bone/implant interface

Speaker

Prof. Douglas Dunlop

Share on:

THINK Medical 3D Printing webinar series

3D planning and medical 3D printing can be game changers for your medical practice. The THINK Medical 3D Printing webinar series will bring you up to speed with the latest developments. Learn from leading orthopaedic surgeons how they use 3D visualization tools, 3D-printed models, and devices in their daily practice and how it changed their way of thinking.