CASE STUDY

The Ultimate Virtual Crash Test Dummy

Researchers at Wake Forest University are using computational human body models of the whole human body that can be employed in the fields of injury prediction, anatomical instructions, and ergonomics studies.

Industry

Healthcare

Key solutions

Materialise Mimics

The impact

Design a virtual crash test dummy with computational human body models

Crashes and their associated injuries are a major public health problem worldwide. Traffic-related deaths over the last 30 years are the equivalent of almost all American war deaths in over 235 years of the country’s existence. In order to prevent crash-related injuries and fatalities, current safety systems need to be enhanced, and computational human body models are an effective means to do so. With this in mind, Francis Gayzik and his colleagues wanted to create a detailed CAD and finite element analysis (FEA) model of the whole human body that can be employed in the fields of injury prediction, anatomical instructions, and ergonomics studies.

Introducing the multi-modality approach

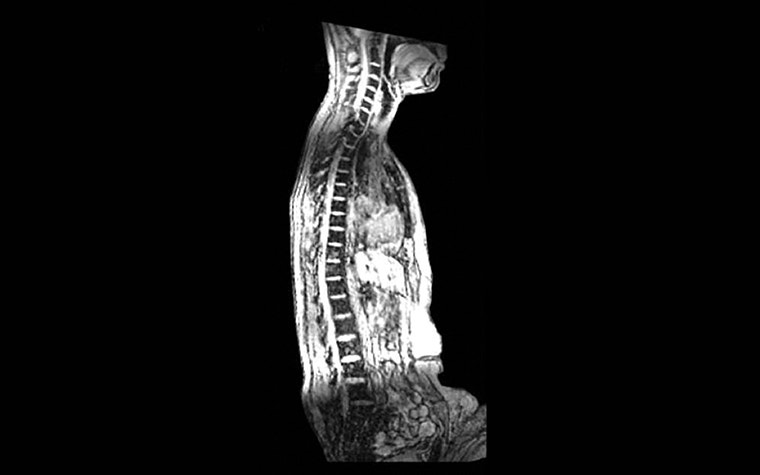

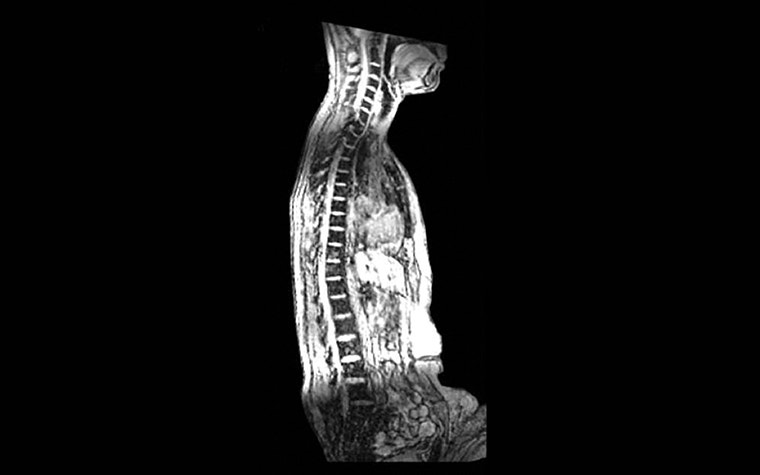

There are already a number of datasets available that are frequently used in the development of FEA models, with the Visible Human Male (VHM) being the most well-known. The research team, however, wanted to improve upon previous development efforts by introducing a novel approach to CAD model development. This was done by basing it on a single living subject, who represented the 50th percentile male and was scanned in multiple modalities and postures. Given the amount of data required for a detailed model, it became clear that there was not one single imaging modality that could provide all the necessary data to develop a full-body model. Instead, they used a multi-modality approach that employs imaging techniques such as MRI and CT, as well as methods for external anthropometry (laser) data collection.

A single male individual, representing the average American male and meeting predetermined criteria, was selected after strict subject recruitment for the study. Following selection, he had to undergo several scanning sessions. Most notably, the subject was scanned (CT, MRI, and laser) in the upright, seated position, in addition to the supine position (CT and MRI). This kind of upright medical image data was, up to that point, unavailable. The researchers took care of several aspects of the imaging protocol that enhanced the accuracy of the final CAD model.

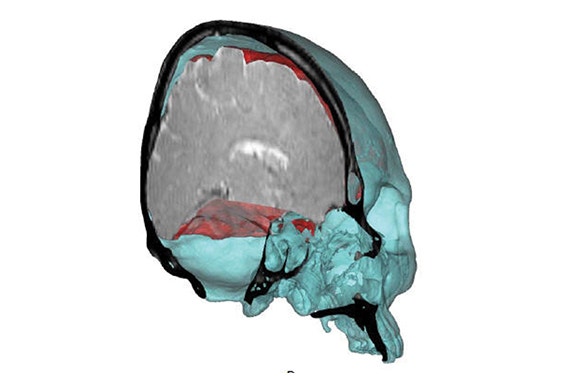

Segmenting and assembling the full body model

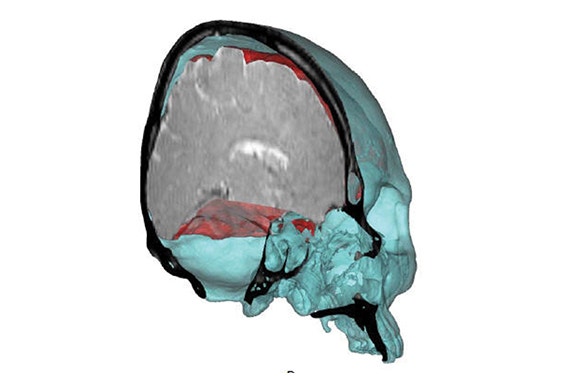

After the alignment and merging of several image datasets, the team started the segmentation process. For this, they relied solely on Materialise Mimics. This software solution encompasses all the tools the team needed to segment their scan data with the utmost accuracy.

The subsequent assembly phase in Mimics Core involved repositioning 3D models, segmented in the supine position, onto scans taken in an upright and seated posture, since the resolution of the supine scans was higher. In some other cases, the team combined its segmented data with 3D models based on literature studies or even on other datasets, but they made sure that the data always depicted an approximately 50th-percentile male.

“Our team at Wake Forest University was very pleased to receive the Mimics Innovation Awards for our work in human body model development. Given the tremendous activity in the field, and quality of biomedical research being conducted throughout the world, it is truly an honor to be recognized for our work. ”

— F.S. Gayzik, Wake Forest University School of Medicine, USA

The final result

The final stage of model development was the CAD phase. The 3D models of the anatomy were converted to a mathematically defined NURBS patchwork. To make sure these structures were amendable for FEA or computational fluid dynamics (CFD) meshing, each structure of the CAD model was made watertight and G1 continuous.

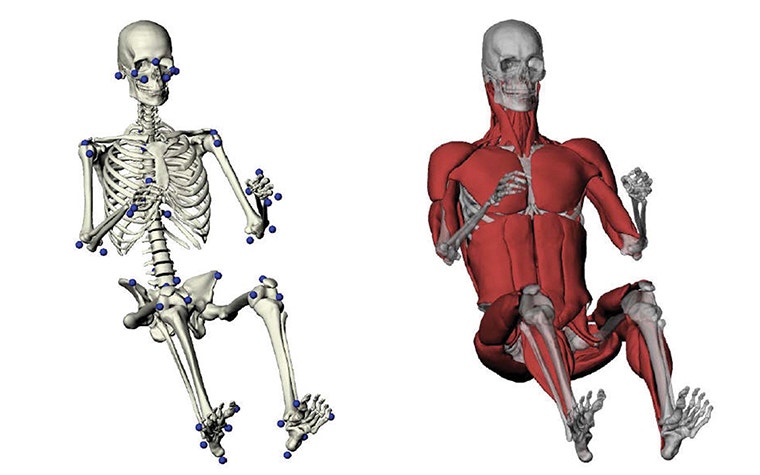

In the end, the team ended up with an outstanding representation of the seated anatomy. Their model of 410 individual components consisted of 9.1% bony anatomy (179 bones), 13.0% organ, and 21.7% muscle. Finally, the 55.3% of interstitial space representing skin, fascia, subcutaneous, visceral fat, and anatomical features was not included in the model.

The constructed model can be used in FEA or CFD models for biomedical studies and the prediction of crash-induced injuries. Additionally, the amount of detailed morphological data acquired can be used as a reference for the average male. A final fact worth noting, is that the imaging and scanning protocols used to obtain the data for this study can be applied to develop models of individuals of various sizes.

The standard in engineering on anatomy

Mimics turns 3D image data into high quality digital models in an accurate and efficient way. Starting from CT, MRI, or 3D ultrasound images, Mimics offers the most advanced image segmentation, the broadest anatomical measurement options, powerful CAD tools for engineering on anatomy and 3D Printing, and accurate model preparation for FEA and CFD.

The authors used Mimics to design a virtual crash test dummy using the following steps:

- Convert CT and MRI images of a single subject to digital models

- Construct a true multi-modal full-body mode

- Pre-process and optimize the full-body model for numerical simulations

Share on: