CASE STUDY

Smoothing the Flow: How Sambon Saves 3 Hours on Data Prep per File

Sambon Precision & Electronics manufactures audio devices (earphones, headphones and speakers) and keypads for distribution in South Korea and overseas. When developing a new product, producing a prototype is a mandatory step in the development process. Sambon 3D prints the prototypes since it’s a fast and flexible method. Unfortunately, their 3D printing workflow wasn’t that smooth, and took up a lot of time for the data preparation team. Using Materialise Magics software, they were able to reduce file repair and platform preparation time significantly.

Industry

Consumer goods

Key solutions

Materialise Magics

The impact

Reduce time spent on data preparation

Create a smoother workflow

3 hours saved on data preparation with better repair and editing tools

A workflow that makes sense: file fixing

Before using Materialise Magics, Sambon’s design team would prepare the CAD file in Rhino and send it to the data preparation team. They would then fix the errors they could and send the file with the remaining errors back to the design team for editing, or to their R&D colleagues. Getting parts with complex shapes ready for 3D printing could easily take half a day.

Now, the file never needs to go back to the design or R&D team. With Materialise Magics, the data preppers can fix most errors automatically and handle more challenging errors manually. Repairing the file now only takes 2 to 30 minutes. On average, Sambon saves 3 hours on file fixing.

“With Materialise Magics, we can easily fix files which have lots of errors, such as overlapping triangles, bad edges, noise shells, etc. We can also cut bigger parts, which enables us to print parts easily.”

— Dongkyu Lee, Responsible Engineer at Sambon Precision & Electronics Co, Ltd.

A workflow that makes sense: file editing and build platform preparation

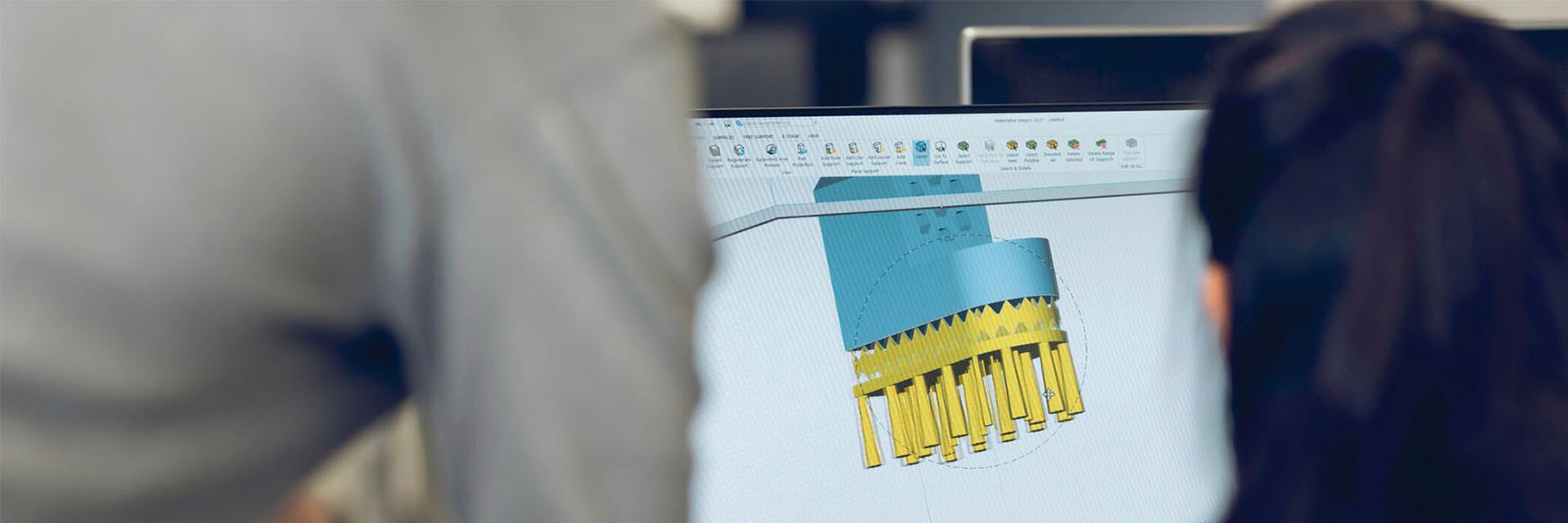

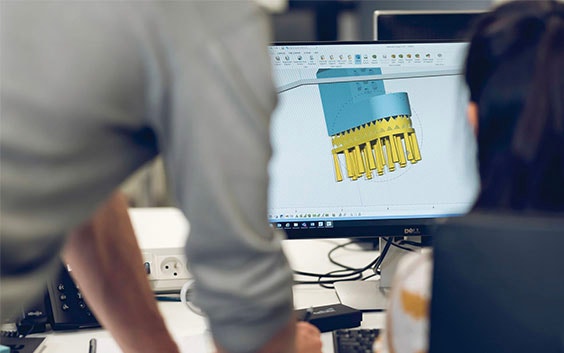

After repairing the STL file, the team edits it: they cut parts that are larger than the platform size (which can easily be assembled afterwards), they hollow solid parts to save material, and more. Sambon also uses the measuring functionality to analyze parts and ensure a successful build. For instance, the software indicates wall thickness, detects colliding parts and helps to keep the deviation between 3D model and printed part within predefined tolerances.

In the last step of the process, it’s time to prepare the build platform. Sambon simply adds the platform of their machine to Magics. Then the advanced positioning and machine management tools allow them to position, rotate and scale the prototypes as they like. And off it goes to the printer. No need to switch software to get a watertight file 3D printed!

Share on: