CASE STUDY

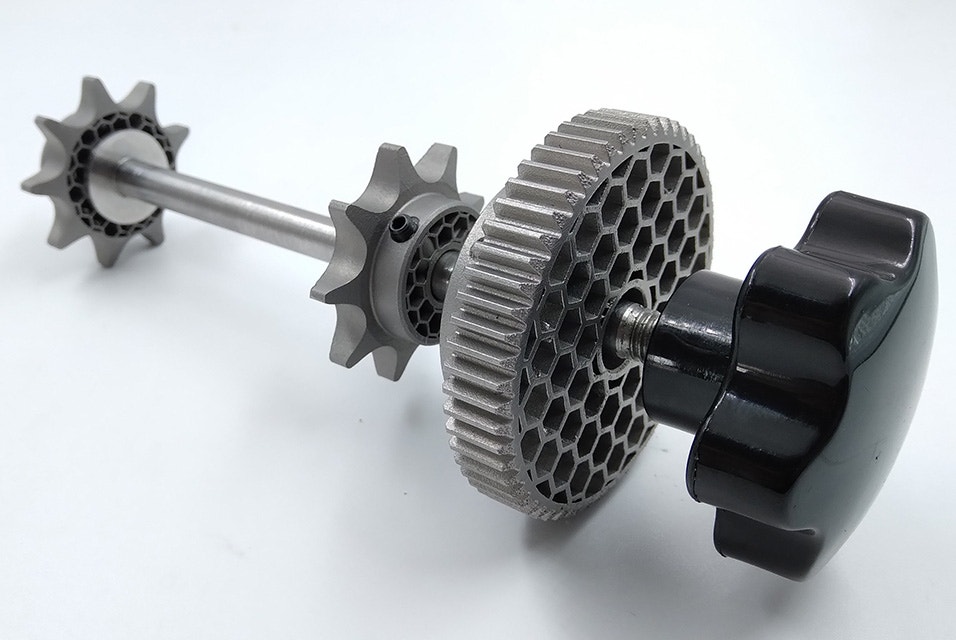

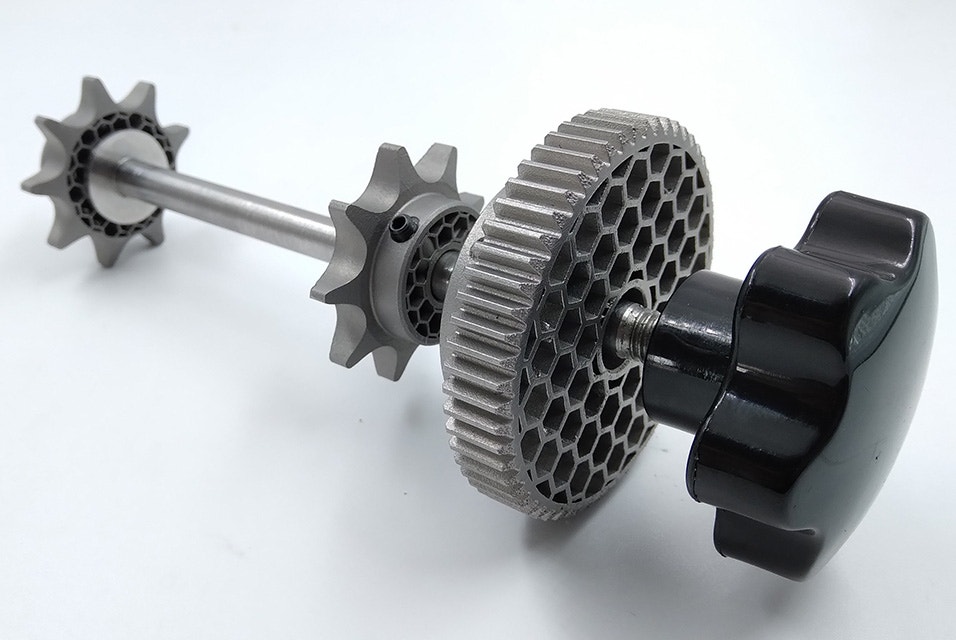

Sweet and Simple: Magics’ Honeycomb Structure Keeps the Gears Ticking at the Il Sentiero Campus

Gears and sprockets are everywhere, with many everyday items and machines using them. From analog clocks and drills to cars and bicycles, they are found in various applications across industries. However, how can you improve on equipment that’s been around for thousands of years? This was the challenge Mario Franchi, Application Engineer for Additive Manufacturing at Il Sentiero, had when he was tasked with making the humble gear and sprocket more lightweight for an internal project. He turned to Materialise Magics and its honeycomb structure for the answer.

The challenge

Create a lightweight gear and sprocket that can withstand high temperatures

The Il Sentiero International Campus is renowned for its experience using additive manufacturing (AM) technologies. The campus uses 3D printing for industrial research projects, collaborating with external institutions to complete projects. For example, the campus revived an antique for the modern age by 3D-printing a 500-year-old book for the TEMART project in partnership with Ecor International.

However, a new project is requested internally for Mario to work on once a month, which usually involves improving a system or a piece of equipment. This time, he was challenged with reducing the weight of components used in a test rig — specifically the gears and sprockets.

“I’m usually required to update a part and follow a set blueprint. But for this project, I had the flexibility and freedom to develop something unique. The only criteria were that the 3D-printed parts should be lightweight and able to withstand high temperatures,” says Mario.

Challenge accepted, Mario leaped at the task and decided to use Magics, design for additive manufacturing (DfAM), and a particularly sweet AM structure.

The solution

Materialise Magics, DfAM, Stainless Steel, and honeycomb structure

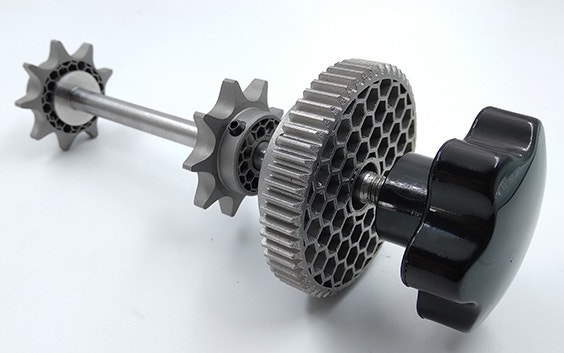

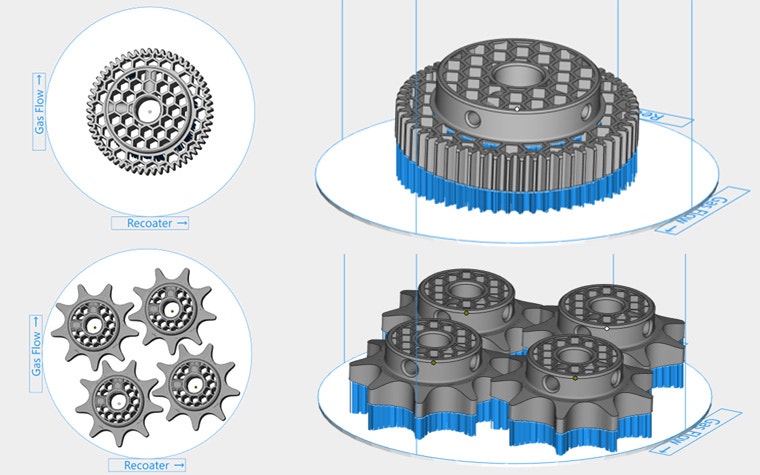

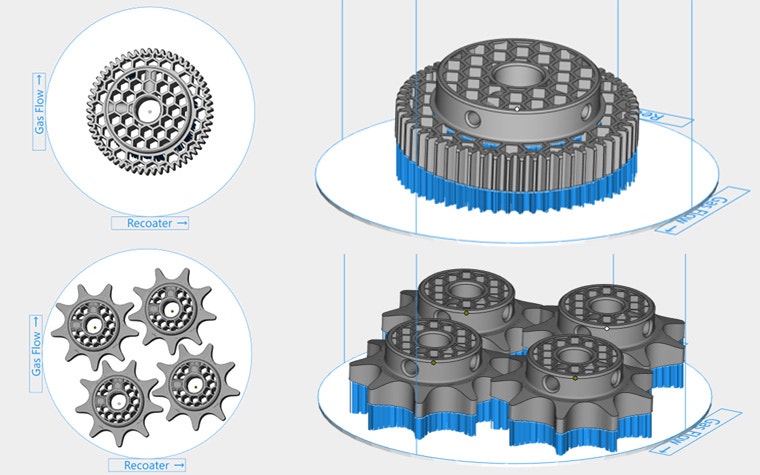

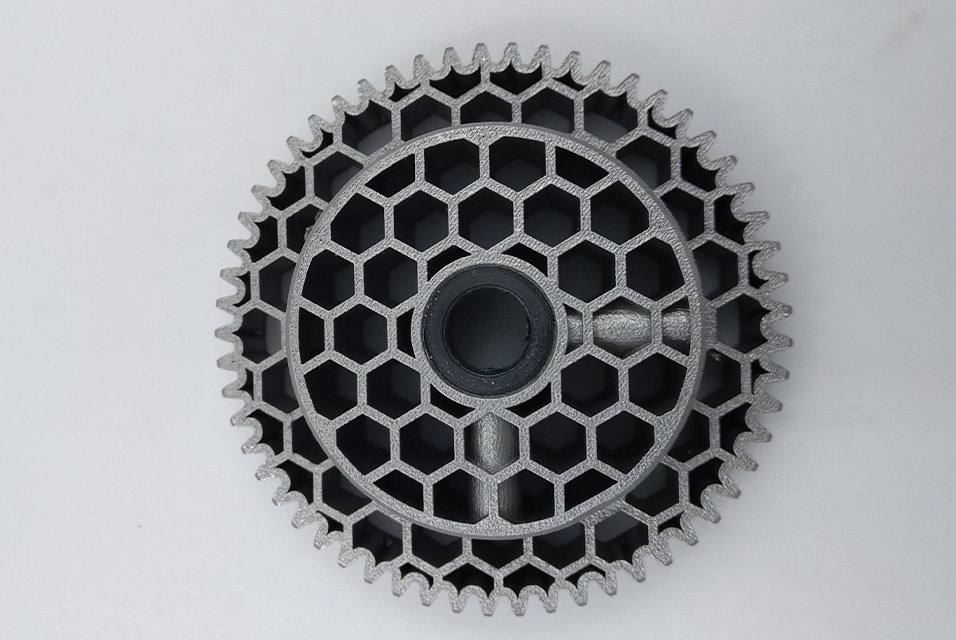

The biggest challenge for Mario was finding the right structure that provided significant weight reduction while ensuring printability and structure stiffness. Luckily enough, Magics fulfilled both requirements. “I wanted to keep my design and 3D-printed part as simple as possible. It only took me a few minutes to identify that the honeycomb structure in Magics was perfect because of its strength (in terms of wall thickness) and its simplicity. Plus, you can easily construct and modify your designs in the software — it literally took seconds and a few clicks of a button — and printability wouldn’t be an issue,” says Mario.

Unlike traditional CAD software, Magics allows users to quickly analyze and edit part orientation and the support structures of a model within minutes without affecting the design’s build prep or printability. In comparison, a lot of CAD software is not as intuitive or flexible and may take around 80 – 90% more time to build and edit, with a greater chance of printability issues or build failure.

Magics and metal 3D printing was the most practical solution for Mario, as creating a honeycomb structure and building the parts using traditional manufacturing techniques would have been too laborious.

“It was easy to set measurements of the wall for the optimum thickness, and Magics allowed me to leave the outer surfaces of the part open, along with the inner cavities of the honeycomb, without risking build failure. This was fundamental for reducing the weight. And printing in Stainless Steel (AISI 316L) bolstered the part's strength and was ideal for the extreme environment in which the part will be used.”

The result

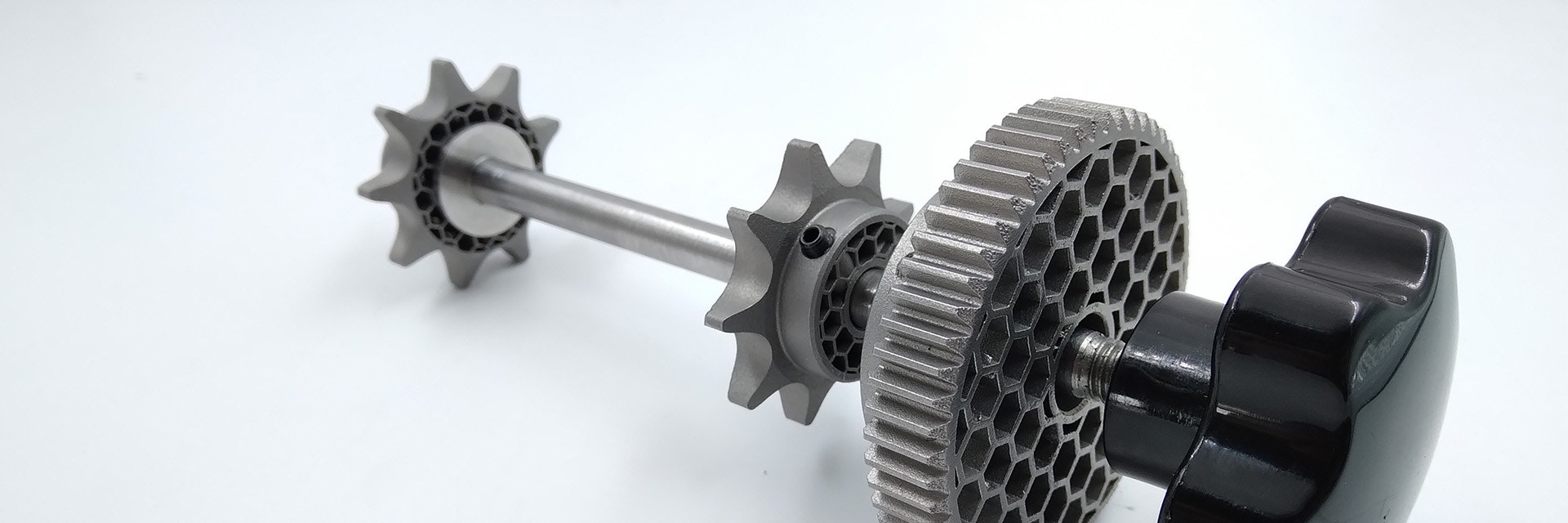

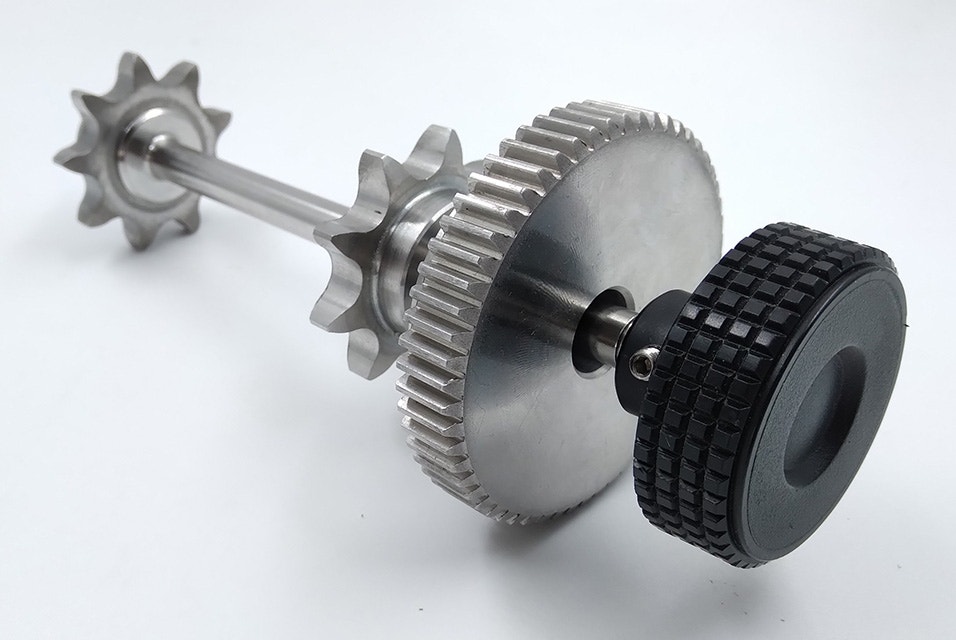

A DfAM re-designed shaft unit — using metal 3D-printed gears and sprockets with a honeycomb structure — that was 46% lighter than the standard model

By combining DfAM, Magics, and metal 3D printing, Mario produced a redesigned 3D-printed gear and sprocket that were lightweight and durable. Due to the honeycomb design and open structure, the remodeled gear was 61% and the sprocket 53% lighter than their traditional counterparts. These pieces will be used in ten shafts. Each shaft with these redesigned components is now 46% lighter compared to the standard models, which means a substantial reduction in weight and material usage — not to mention parts that are reliable and easy to print.

“The beauty of the honeycomb is that it can be applied to anything else. I will definitely propose it for other projects; its versatility makes it practical for many applications. Magics is user-friendly and practical because you can prepare and manage the 3D printer’s parameters in one software — this takes the complexity out of the design and build process,” enthuses Mario.

Magics and metal 3D printing allow anyone to easily break the mold and redesign parts. “Magics empowers users to express themselves like no other software, and AM enables geometries that are unachievable by standard manufacturing processes like injection molding,” explains Jeremy Levecq, Sales Application Engineer at Materialise.

Success in 3D printing has never tasted sweeter…

All images courtesy of Il Sentiero International Campus

Share on:

This case study in a few words

Machinery and equipment

- Materialise Magics

- Honeycomb structure

- Design for additive manufacturing (DfAM)

- Stainless Steel (AISI 316L)

- Metal 3D printing (metal powder bed fusion)

- Significant time-saving and weight reduction

- Easy to implement and adjust the orientation and support structures

- DfAM flexibility