CASE STUDY

Life-Changing Hip Surgery Makes 81-Year-Old Sing and Whistle Again

Orthopaedic surgeon Mr. Douglas Dunlop was able to restore his patient’s mobility and independence by using a 3D-printed hip solution in a complex re-revision surgery.

Industry

Healthcare

Key solutions

3D planning

3D-printed anatomical model

3D-printed surgical guides

aMace hip implant

The impact

Personalized solution for a complex problem

Higher accuracy and predictable patient outcomes

Stop the revision cycle

The challenge

Plan and execute a successful hip re-revision

Hip re-revisions are unfortunately not uncommon: data from joint registries show that 27% of revisions are not initial ones, and those re-revisions have a threefold higher chance of failure compared to initial revisions.

At the age of 81, the patient was suffering from a Paprosky type 3B acetabular defect and had already undergone hip revision surgeries prior to seeking the help of Mr. Dunlop, Consultant Orthopaedic Surgeon and Honorary Professor of Orthopaedics at the University of Southampton.

The previous revision reconstruction of this particular patient (cemented PE liner with cranial metal mesh) failed due to the cup's loosening and migration to the postero-cranial region. This resulted in a limited amount of bone stock, particularly in the postero-cranial region, which poses challenges towards creating a stable and lasting reconstruction of the acetabulum.

The solution

Personalized, 3D-printed aMace implant

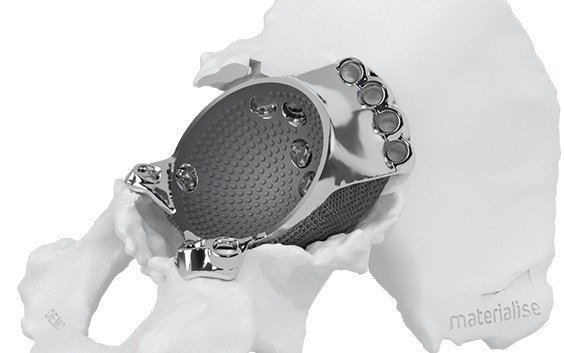

Collaborating with Materialise clinical engineers, Mr. Dunlop was able to carefully plan his patient’s surgery up front and approve the design of a 3D-printed implant to achieve the desired mechanical reconstruction and fixation, tailored to fit the defect.

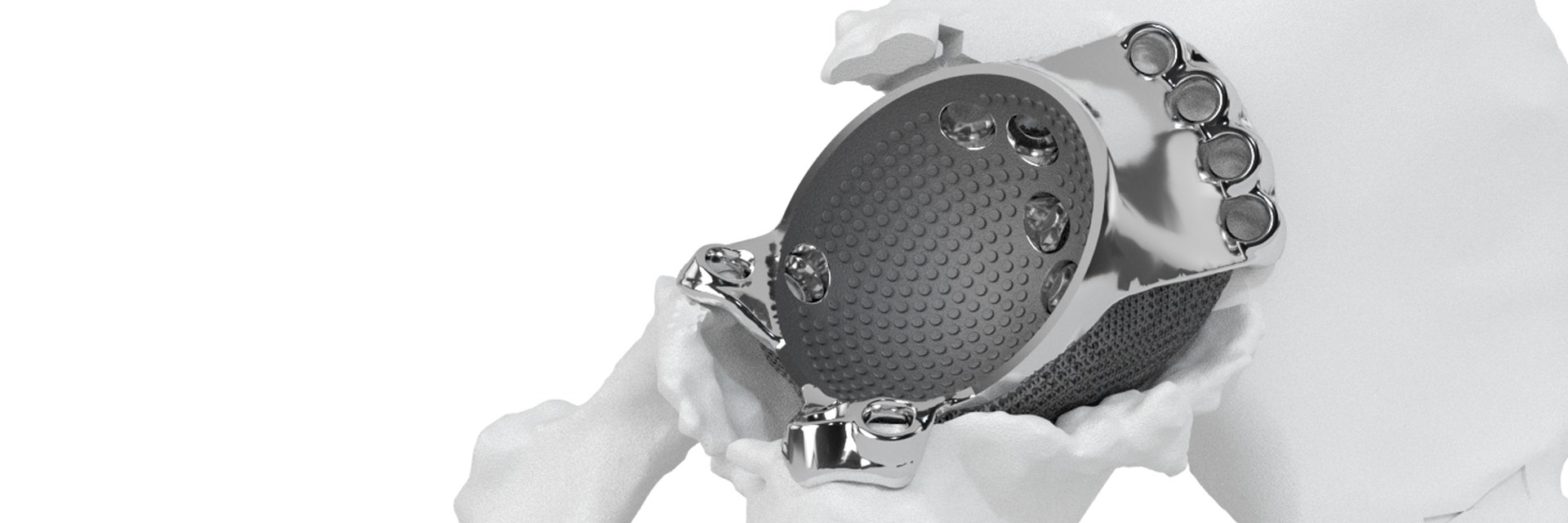

3D printing makes it possible to create very specific and complex shapes. When presented with bone defects, an aMace personalized implant is a unique way to match the medical considerations with the complex mechanical requirements of such an important moving part of the human body. The intricate porous structure on the back of the aMace implant, which enables bone ongrowth, is another feature that can be achieved using 3D printing.

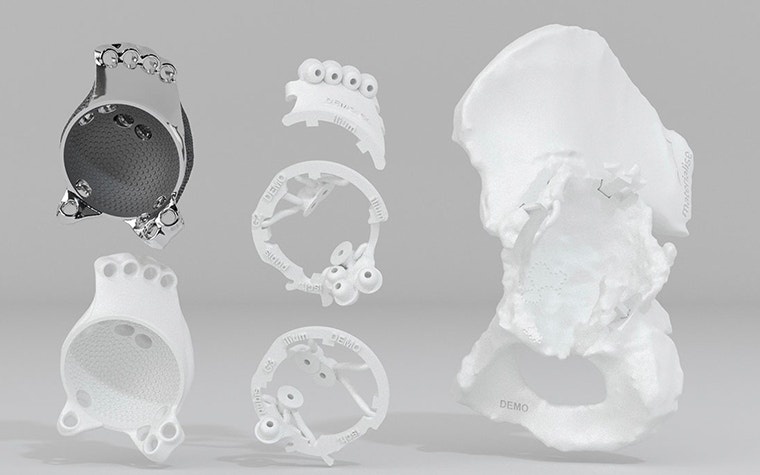

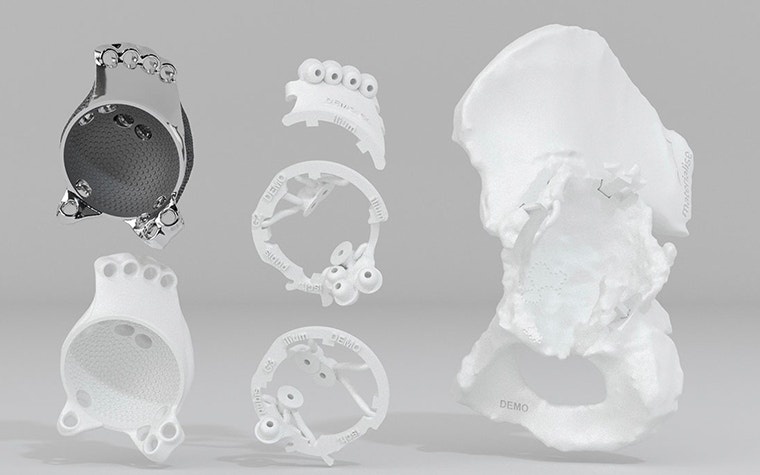

Thorough 3D surgical planning is a key benefit of using aMace implants. Before surgery, a Materialise clinical engineer creates 3D models and suggests a correction procedure. The whole planning process is fine-tuned with the surgeon through the SurgiCase cloud platform for feedback and approval.

Once approved, a 3D-printed set of instruments, plus the metal implant itself, goes into production. In addition to the implant, the surgeon receives a plastic anatomical bone model and implant trial model which serve as a reference to prepare the site and position the implant correctly. The drill guides are used intraoperatively to place the screws in the planned position.

In this case, the 3D-printed implant reconstructed the center of rotation to the desired location and orientation, and provided enough support even with the limited bone available, especially in the postero-cranial region.

The result

Successful re-revision and vastly improved quality of life

The preoperative planning and custom fit of the implant were a great added value for this case, resulting in a stable reconstruction even with the missing bone supero-cranially. The outcome was a successful re-revision and a satisfied patient who regained his independence.

“My dad's quality of life has improved beyond measure. The closest he can get to describing it is to say that a big lottery win could not make him happier!” said his daughter.

The patient received the anatomical model of his bone after the surgery, which he used intensively to explain his solution to friends and family, explains his proud daughter.

“All who know Dad and the severe debilitation he experienced prior to his 3D surgery are amazed by the transformation. ”

— Patient’s daughter

A study by Mr. Tack, Health Researcher at the Ghent University, underlines that the aMace implant can be highly cost effective because it addresses the complications leading to further revisions compared to other systems. The aMace solution prevented any further revisions for this patient so far.

The patient’s daughter explains, “All who know Dad and the severe debilitation he experienced prior to his 3D surgery are amazed by the transformation; he looks 20 years younger and has regained his independence. For me as a daughter, it is lovely to hear my Dad singing and whistling again.”

L-102639-01

Featured products and services

Share on: