CASE STUDY

HeyGears Creates Personalized Prosthetic Designs in Seconds with Materialise Software

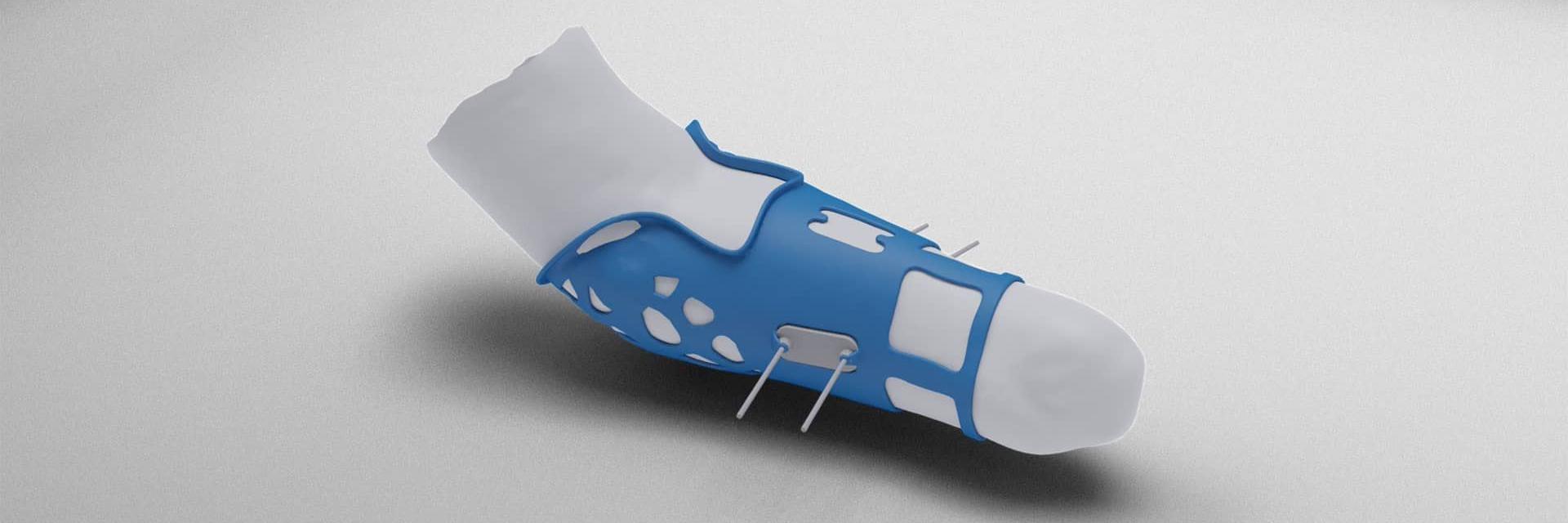

For people in need of a prosthesis, HeyGears created a customized robotic hand that detects nerve signals in users' forearms, giving them a higher degree of dexterity and, therefore, a higher quality of life. Customization like this is becoming a goal in many industries. And often, companies like HeyGears turn to 3D printing to achieve it because of the technology's speed and freedom of design.

HeyGears designs their prosthetic hands based on a scan of the forearm for a perfect fit, but designing it manually takes hours and increases the risk of error. In other words: it's not scalable. That's why they came to Materialise to automate the design process from point cloud to printed part, which we achieved with our API technology and automation platform.

Industry

3D printing service provider

Key solutions

A custom-made API to automate the design workflow

The impact

Reducing time spent on designing personalized prosthetics

HeyGears is an innovation-driven Chinese technology company that provides digital manufacturing solutions. This case focuses on their 3D-printed, customized, intelligent prosthetic sockets that connect to prosthetic hands. Prosthetics require plenty of personalization, and this is one of the main reasons HeyGears relies on 3D printing for this application.

Challenge

Reducing manual effort

As you can imagine, designing a bespoke prosthetic can be a very time-consuming process. Not only do you have to create the base design, but you must also add the details that make this part the perfect fit for the customer.

The HeyGears designers had to follow a lengthy, detailed instruction manual each time they built a digital design. Following these steps meant up to one day of manual work consisting of mundane, yet required, actions. Without a method to standardize the workflow, the process had to be started from scratch for each and every design.

From traditional manufacturing to mass customization

HeyGears recognized that these manual, routine tasks were taking up time that their experienced designers could use instead to innovate and improve their offering. The tedious process also meant that when the time would come to scale up, they would have difficulty doing so. That’s why they turned to Materialise’s software team to help them automate these steps.

Solution

Automating the full design process with Materialise APIs

When addressing 3D printing challenges such as this, it’s highly beneficial for companies to look to experts specialized in the field. Materialise has 30+ years of expertise in 3D printing, so our software team was the perfect fit to help take on this challenge.

Our software experts began by working with HeyGears to understand their product and design workflow. Based on this knowledge, our team worked with HeyGears to develop a custom-made API (application programming interface). So, what exactly does this look like in action?

“With this API, designers can have a unique design ready in just a few clicks,” explains Nils Faber, Software Research Engineer at Materialise. “We considered the many parameters their designers must add in each time and automated the steps required to implement these variables.”

Previously, when they needed to change a design — adding more sensors for different robotic hands, for example — the designers would often need to undo steps to get to the point where they can best make the adjustment. Using the API, they can avoid this backtracking and instead make the update with just one click.

Another game-changing benefit of workflow automation is the capability to see immediate visual feedback while designing. For example, as HeyGears designers create a model for a prosthetic, they can now instantly see a render of the design once they define the parameters in a couple of clicks via the API. This improvement enhances the ease of mass-customizing, allowing the team to complete tests on the design quicker and more efficiently.

Result

Designs in seconds

Clearly, the time saved was a huge benefit gained by incorporating the API into HeyGears’ workflow. What used to take up to a day of following pages and pages of instructions can now be accomplished in minutes with just a few clicks of a button.

“By collaborating with 3D printing pioneer Materialise, we are able to further automate the design flow, reducing complexity and generating significant time benefits.”

— Heyuan Huang, Vice President and Co-Founder of HeyGears

Optimizing HeyGears’ design workflow was crucial to achieving their main goals, such as gaining more time for innovation and scaling production. Since this prosthetic solution is unique to each individual, HeyGears needed to focus their design time on optimizing the part for each person. By reducing the time spent on monotonous tasks, they could do so while giving their team more time to create new and improved solutions.

Using the API to streamline their process also empowers the team to accomplish mass customization in two major ways. The drastic difference in design efforts means that their output can grow exponentially — creating each design requires significantly less time. Repeatability is also a must when it comes to scaling up, so that’s another challenge area their team needed to tackle. Because each designer follows such a large manual and works in their own way, differences among the designs are bound to occur. But by straightforwardly providing parameters via the API, variations in design are much less likely to occur.

Automating the full design process with Materialise API’s

“For the creation of 3D-printed, smart prosthetics, we are always looking for new ways to enhance our design process,” says Heyuan Huang, Vice President and Co-Founder of HeyGears. “By collaborating with 3D printing pioneer Materialise, we are able to further automate the design flow, reducing complexity and generating significant time benefits. This allows us to focus on what really matters: creating a more comfortable experience for our customers.”

Share on: