CASE STUDY

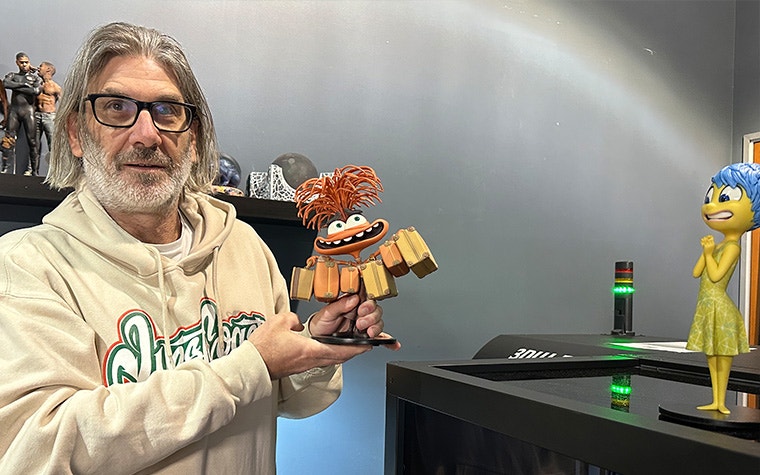

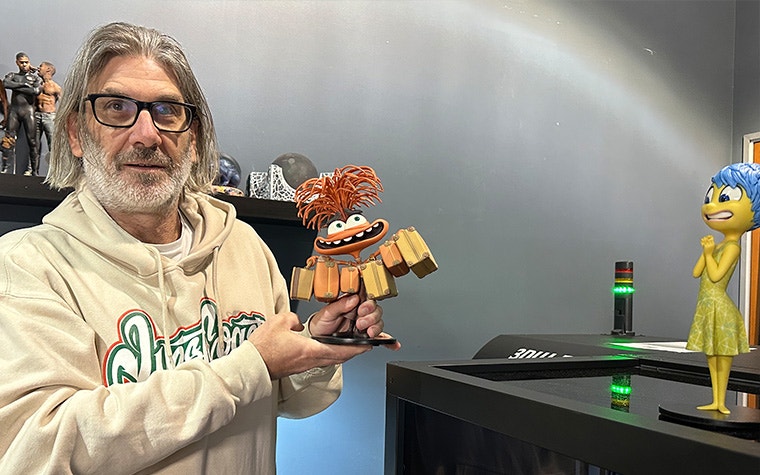

How Gentle Giant Studios Revolutionized Their Use of AM and Accelerated Workflows by 65%

Harry Potter, Yoda, Elsa — every day, Gentle Giant Studios brings your favorite characters to life. The team has come a long way from sculpting in clay 30 years ago. Today, they employ techniques like 3D scanning, 3D modeling, and additive manufacturing (AM) to streamline the iteration phases, collecting feedback digitally before investing the effort into creating a physical model. Let's hone in on the studio's central hub — their 3D printing lab — to learn how their processes have evolved to become what they are today.

Industry

Art and design

Key solutions

Materialise Magics

The impact

- Faster, more advanced AM workflows

- Technology-neutral software

- Hands-on learning

Challenge

Developing AM skills and speeding up workflows

Jason Lopes is no stranger to 3D printing. In fact, he's been using the technology since 2007, and his passion and aspirations for AM continue to climb. So when he joined Gentle Giant Studios in 2023, he immediately assessed their 3D printing setup to determine where his expertise could help the lab improve.

"When I joined, the team was using generic build prep software for automatic fixing," explains Jason. "This software can technically make files printable, but it lacks the capability to help people learn. To get the best results, you need to learn quality modeling techniques before relying on build preparation software. Software with such basic functions doesn't enable this type of development."

In addition to the potential to further develop their AM skills, Jason also recognized that there was room to accelerate workflows and expand their digital systems to improve the traceability of their projects. "The minute I saw their setup, I said, 'We need Magics in here,'" shares Jason.

Solution

Introduce Magics for data and build preparation

Jason is a long-time user of Magics — he's used the software since version 4 and is a strong advocate. He has introduced it to every company he's worked at and Magics has always made an impact.

"Magics has always been my weapon of choice," says Jason enthusiastically. "In Magics, I can check for errors, I can modify parts to make them printable, I can complete Boolean operations — that's huge in my world. But beyond that, I can make the business side of things simpler. For example, by estimating the costs of projects myself before sending them out."

“With Magics, we have a program that keeps up with how quickly we work in the studio.”

— Jason Lopes, Chief Technology Officer, Gentle Giant Studios

Many of Gentle Giant Studios' creations are lifesize, meaning they have large designs to print and complex files to manage. As Jason's 3D printing projects have evolved alongside Magics, he notes that Magics has always kept up with the ever-growing file sizes:

"We don't feel limitations when processing operations. You always get a real-time update on Magics' progress. It's really exciting, especially as we bring in color data with our photogrammetry work. Years ago, I never would have thought it was possible. But with Magics, we have a program that keeps up with how quickly we work in the studio."

Such large models aren't printed all in one go. They're printed in multiple pieces and assembled during the finishing stages — for context, Jason clarifies that a model of himself would likely be 14 pieces. This adds even more complexity, as each part needs to be tracked properly with all the finishing specifications.

"We have many different workflows to keep track of," explains Jason. "Some parts go to our model shop for cleanup to be a master pattern for casting. Some go to be painted. So you can imagine the type of instructions that need to accompany the parts. That's where Magics' reporting function comes in handy. Every department knows exactly what's coming to them, what they need to do, and where the part needs to go next. It works very, very well."

Result

65% faster workflows

Introducing well-rounded software like Magics into their workflow made a major difference. In fact, after testing time gains, the team found that data and build preparation was 65% faster with Magics, eliminating the bottlenecks and frustrations that accompanied waiting for their previous software to process such large, complex files. And with these improvements, they've been able to expand their customer base and take on more projects.

As for the team strengthening their AM skills, Jason finds after just one or two months, they show significant growth: "I have an example right now where I unleash Magics into the hands of someone new and their learning curve is exponential. It makes them a better modeler — an expert in geometry — without even realizing it."

What's next for Gentle Giant Studios? Jason is looking forward to the new Magics 28 entering their toolkit: "I've joined the Magics user group at AMUG the past couple of years, and Materialise always takes our feedback into account and sets the right expectations for what's to come in future versions. With this year's upgrade, I'm really looking forward to the dark theme and the performance improvements."

On a more personal note, Jason would like to continue promoting color 3D printing and seeing progress in this field. In addition to specific improvements to color printing — like assigning colors to specific regions of a part's geometry or adjusting opacity — he hopes to see more industries introduce color into their AM productions.

We can't wait to see what Gentle Giant Studios comes up with next! If you'd like to learn more about this case and how you can make a difference in your AM workflows with Magics, come visit us at AMUG and RAPID + TCT.

RAPID + TCT: April 8 – 10, 2025, Detroit, booth 2825

AMUG: March 30 – April 3, 2025, Chicago, booth D82

Share on: