CASE STUDY

From Castor Bean to Colorado: Meet the 3D-Printed Eco-Performance Optics Inspired by Nature

Sustainability. Innovation. Community. These three pillars are the foundation of Zirkel’s 3D-printed eco-performance optics and the reason why bio-based PA 11 was the ideal material. Discover the story behind these incredible frames, and the company determined to do less harm.

Industry

Eyewear

Key solutions

- PA 11

- Selective laser sintering

- Design support

The impact

- Sustainable materials limit waste

- Iterative design process

- Fewer materials used than in reductive techniques

Built in the shadow of the Colorado Rockies, it’s clear to see what inspired Zirkel’s line of performance optics. They’re beautiful. Rugged. Built to last. Tried and tested on rough and ready slopes and mountain roads. Their names are equally fitting: meet the Teddy Grizz, Sawtooth EXPLR x 3, and Peak Pioneer EXPLR x Bison.

But what makes this collection truly unique is how it is made. Each frame is 3D printed by Materialise using bio-based PA 11, a polyamide derived from castor beans. The remaining components also come from Europe and contain no virgin petroleum. These decisions are based on more than logistics — they stem from a deep-held belief in doing better for the planet.

“Materialise has been a hugely valuable partner for us. Being leaders in 3D printing, combined with their partnership with Arkema and the fantastic quality of materials, has helped us create a highly consistent, highly effective, extremely well-received product.”

Sustainability comes first

To really understand Zirkel, you need to understand Steamboat Springs, Colorado, and the people who call it home. This quaintly named town has produced more Winter Olympians than any other, and its outdoor-minded community has always been deeply in touch with nature. Unsurprisingly, Steamboat native and Zirkel co-founder Justin Reiter was keen to instill that connection in the company’s foundations.

“Being in the winter sports environment, I recognize that all the gear we use — snowboards, goggles, boots, jackets — has a footprint. Zirkel was founded on the premise of what we can do better as an industry that is wrought with pollution, wrought with waste, wrought with fast fashion,” he begins. “We asked ourselves, how can we create a product that performs better and does less harm to the Earth while at the same time creating something innovative and unique that does not exist on the market?”

“Any designer could create a single frame, but can you replicate that? Bring it to market? Give everyone the opportunity to enjoy it and disrupt the market by showing what’s possible? Materialise can.”

Materialise: The ideal partner for eyewear

That approach, plus an awareness of the integral differences between reductive and additive manufacturing, quickly led Zirkel to Materialise. As leaders in both 3D printing and eyewear production, there was no better partnership to bring this sustainable vision to life.

Materialise’s experience of working with PA 11 was particularly appealing. Statistics show that additive manufacturing with the bio-based polymer has half the CO2 impact of working with PA 121 and greatly reduces waste in comparison to CNC techniques — something Justin attributes in part to Materialise’s production efficiency and knowledge.

“It’s not enough to have a polymer that’s fantastic and beneficial for the environment, being 100% sustainable and from a non-food competitive, non-rainforest invasive bean like the castor bean,” he explains. “If you don’t have a team that knows how to implement it or designers that know how to work with it, it might as well be a tube of toothpaste — it doesn’t mean anything.

“The collaboration we’ve had with Materialise, whether through our original designer Carl Allen or with Roman [Plaghki, Design Services Manager at Materialise], allowed us to take a 360° approach to designing and producing these pieces at scale. Any designer could create a single frame, but can you replicate that? Bring it to market? Give everyone the opportunity to enjoy it and disrupt the market by showing what’s possible? Materialise can.”

“They’re incredibly durable, incredibly light, and overall just a fantastic pair of glasses.”

Built to last

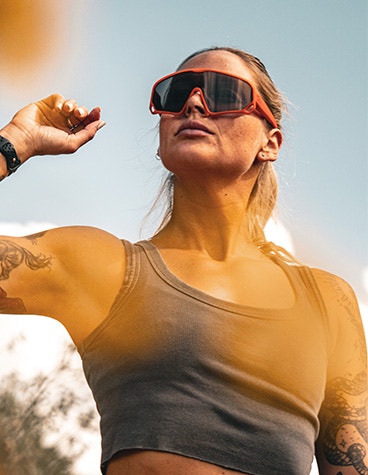

Of course, sustainability is only one part of the story. The eyewear still had to meet the community’s needs above all else; optical clarity, fit, weight, and performance were key. So far, the feedback is highly positive, and it’s hard to find a more qualified focus group to give it: Olympian Cody Winters, adventurer Colter Hinchliffe, and Trophy of Nations Champion mountain biker Shawn Neer are just some of the names to test the frames in their challenging environments. It’s a great source of inspiration when it comes to optimizing each frame.

“With 3D printing, we can make minute changes in our manufacturing and fit process to ensure our glasses meld seamlessly with anyone’s outdoor adventures or pursuits. You don’t want to know that they’re on,” Justin tells us. “The greatest compliment an athlete testing our frames can give is 'I forgot I was wearing them.' Of course, we want them to look fantastic, but these are eco-performance optics, first and foremost. Whether they're going fly fishing, trail running, biking, hiking, backpacking, or just walking their dog, we want our frames to be the first thing they reach for, then forget about them as soon as they’re on.”

Adaptability means wearability

Given its digital nature, 3D printing has always been a good fit for eyewear, and Zirkel’s collections were no exception. Working closely with Materialise, the team was able to iterate quickly and affordably by making changes to a CAD file rather than a mold. It’s a freedom that Justin finds incredibly valuable and integral to his company’s environmental goals.

“With an injection-based technology, we’d be committed to a mold because of the investment it takes to produce — even if it’s not perfect, you have to produce a set number of frames to get a return on that investment,” he tells us. “That’s not the case with 3D printing. We’re reducing resource usage at every step, and we can pivot rapidly, innovate on the fly, and do more with less.”

The rapid expansion of Zirkel’s product lines is a perfect example. It began with the realization that the Sawtooth, Zirkel’s stiffest model, didn’t always fit those customers who Justin diplomatically described as “larger in skull.” By making a small adjustment to the internal temple width, the team created a new, wider variant — the Sawtooth W — without impacting the lens placement, and all within four hours.

Similar adjustments followed in other lines, such as adding or removing side shields, changing from a double bar to a single to create more of a lifestyle piece, or increasing coverage. Before long, a line of four turned into 12.

“Within 13 months, we had a 12-piece collection of completely new styles that are 100% custom — every single pair of glasses that someone gets from us is going to be one of a kind that’s never existed before.”

From Colorado to the world

For Zirkel, the next step is to bring these frames even further afield. Discussions are ongoing with distributors in Japan, Mexico, Austria, and China — meanwhile, their appearance at events like Sea Otter has already led to admiring glances from big-name competitors. It’s a collection with the potential to disrupt an industry.

“Materialise has been a hugely valuable partner for us. Being leaders in 3D printing, combined with their partnership with Arkema and the fantastic quality of materials, has helped us create a highly consistent, highly effective, extremely well-received product,” enthuses Justin. “They’re incredibly durable, incredibly light, and overall just a fantastic pair of glasses.”

Want to rock a pair for yourself? Find Zirkel’s eyewear on their official website or contact the team on Instagram.

1 Materialise Sustainability Report 2023, Page 37

Share on: