CUSTOMER STORY

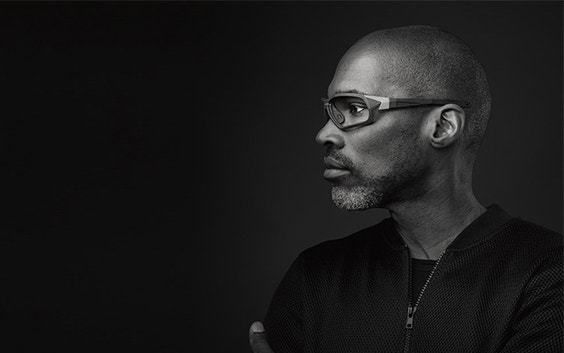

SEIKO’s Xchanger 3D Printed Sports Eyewear Collection Wins Silmo d’Or Award

When the SEIKO Xchanger collection of 3D-printed sports eyewear was introduced at the Silmo optical fair in Paris this month, it won the prestigious Silmo d’Or Award for sports equipment. With this collaboration between SEIKO Optical Europe, Materialise, and Hoet Design Studio, 3D Printed eyewear is making its presence known in the eyewear industry. Here’s what this award-winning collection offers the sportively inclined amongst us. Combining performance, comfort and personalization, so you never have to exchange these elements for each other: instead, the Xchanger lets you keep all these and exchange frame components instead to best fit your style and sport.

“From the sketch table to introduction at Silmo, it took SEIKO, Hoet and Materialise six months of intensive collaboration to get a complete product ready to market with the high standards that SEIKO expects. Our anatomical fitting software suite was used to resize the frames despite the high curvature of the lenses and other requirements. We’ve worked hard on making the most of 3D Printing for the Xchanger collection.”

— Alireza Parandian, Head of Global Business Strategy for Wearables

SEIKO Xchanger 3D-printed sports eyewear

Personalization: the modularized Xchanger frame

The Silmo d’Or Award winning Xchanger collection is designed in a modularized form, allowing you to exchange individual components to customize your frames for your sports. Thanks to Materialise’s proprietary software for resizing and anatomical fitting, the Xchanger collection comes in five frame sizes and two temple sizes. Besides, each of the components can be ordered in any of nine colors, creating endless possibilities for uniquely customized eyewear frames. You can also choose between three inclination angles, making sure you have the optimal inclination for the sport of your choice.

Freedom of design: more functionality

The Xchanger collection benefits from functionality that would not be possible with conventional manufacturing techniques, thanks to the engineering and design freedom offered by 3D Printing. Two examples: the anti-fog ventilation system and the frame curvature. Cold outside temperatures combined with the wearer’s exertion – an unavoidable and very familiar combination for winter sports enthusiasts – lead to fogging and reduced visibility. How do you counter that? Xchanger has a validated anti-fog ventilation system that ensures proper air circulation, to keep visibility clear. Have no fears, keen skiers. In addition, to keep visibility at a maximum, Xchanger features high-curvature lenses that wrap around the face for wider viewing angles. Hoet also designed a special changing mechanism for the lenses, integrated into the frame, which lets you easily change lenses yourself by pinching the frame at the nose-bridge.

Certified material: built to last

Sports gear is often subject to demanding material requirements: you need eyewear that’s strong enough to stand up to arduous environmental conditions but light enough to be supported effortlessly by your nose and ears. The Xchanger frames are 3D-printed in a certified bio-compatible material with a silk-like molecular structure that is lighter than titanium and stronger than acetate: extremely lightweight but highly resistant at the same time. Topped with a super-resistant coating, you get glasses that are built to last, even while you exercise extreme sports.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.