CUSTOMER STORY

Cooperation between Radiology and Orthopaedics Results in In-Hospital 3D Lab and 3D Anatomical Models

The orthopaedic department at the AZ Monica Hospital consists of innovation-driven caregivers who believe that 3D printing orthopaedics has become an essential tool to improve patient care. They believe that it should be part of medical imaging and that close collaboration with the radiology department is essential.

Located in Antwerp, Belgium, the orthopaedic department of the AZ Monica Hospital has a worldwide reputation of providing excellent patient care and hosts national and international fellowship programs in different orthopaedic sub-disciplines. Patients with very complex problems, including top athletes, travel the world to go to AZ Monica for their orthopaedic treatment. Residents from all national universities participate in their training program. With 20 orthopaedic in-house surgeons, AZ Monica has one of the largest orthopaedic departments in the country.

Last year already, between 60 and 70 knee and wrist cases were handled in the hospital using in-house 3D visualization and/or surgical planning. And in January 2017, a 3D-printing lab was deployed in the hospital, where 20 models have been printed so far.

It is a gradual process, and it takes a lot of time to incorporate 3D printing in your hospital successfully, says the team that started the hospital's 3D printing lab at the point of care. You need a team of people with different skills and roles. It's not a one-man show, they say. It's really a team effort. So, how did they do it?

How did 3D printing gain momentum at AZ Monica?

Already back in 2009, Dr. Frederik Verstreken, a hand and wrist surgeon at the orthopaedic department of AZ Monica, treated his first case with Materialise using SurgiCase, a platform that helps surgeons with preoperative planning and personalized guides and implants. In the meantime, he has dealt with over 100 cases involving 3D printing with Materialise.

In 2013, the orthopaedic team expanded and started using in-house 3D technology, mainly for research purposes. Between 2013 and 2017, the interest in 3D technology for clinical applications such as anatomical models, virtual analyses, and surgical planning increased noticeably.

A good 3D model begins with high-quality medical image acquisition. Therefore, radiologists play a crucial role right from the start. Dr. Linus Swinnen, the lab's radiologist, contributes to the whole process with his anatomical and medical imaging expertise. He works in close collaboration with radiographer Sander Van den Wyngaert, the man behind the machine and the models. As a radiographer, he takes care of the image acquisition, and as a 3D lab collaborator, he converts the medical images into 3D segmented models in Mimics inPrint. When needed, they consult the workflow and particular cases with Annemieke Van Haver, a Ph.D. in biomedical engineering who has been involved in 3D research and applications in the lab since 2013.

Why use medical 3D printing?

The benefits of 3D printing technology were already clear during the first case, a distal radius malunion. Dr. Verstreken explains that the technology allowed them to perform surgery in less time, using less fluoroscopy and with less risk of complications. Although it was possible to do the surgery without 3D technology, the use of it helped him with precision.

“Without this technology, there’s a lot of eyeballing during the surgery, and the chance of restoring normal anatomy is much lower,” says Dr. Verstreken. “We were also able to do cases that would not have been possible to do without this technology, like intraarticular corrective osteotomies.”

In Dr. Verstreken's opinion, reasons for incorporating 3D printing in many of their cases are plenty: better-prepared surgeons, more precise planning of surgical procedures leading to less time in the OR, less radiation during surgery, and better final outcomes.

“Before,” Dr. Verstreken says, “we based our decision on the information we received from the radiologists, what they decided to provide. With the anatomical models, surgeons get a more complete view of the anatomy and they can proceed with virtual planning of complex surgical cases.”

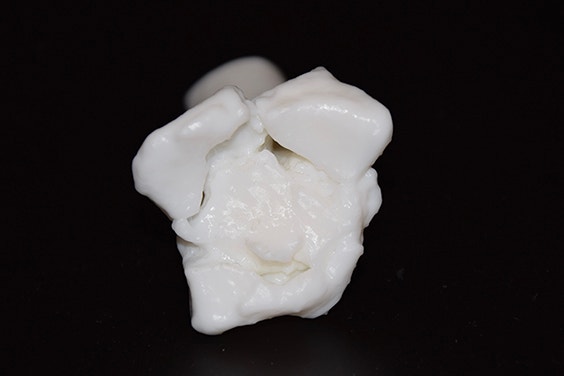

“This is a 3D-printed model of a distal radius with a complex intraarticular fracture. You can see all the fracture lines and displacement on the anatomical model, things we cannot see during the surgery. This is inside of the joint, so we’d have to cut the ligaments and take the joint out of its position, which causes much extra damage. Now, with anatomical models, we do not have to do this anymore. The anatomical model allows us to prepare much better for complex procedures.”

Why set up a 3D lab in-house?

An in-house lab enables the team to react faster to acute cases. Dr. Verstreken says, "if there's a fracture coming in our clinic today, it is possible that we need to do the surgery tomorrow or the day after. Having a 3D lab in-house enables us to create a 3D-printed model and have it on hand in less than 12 hours.”

Dr. Swinnen, the radiologist, became strongly convinced that they could do a better job by delivering 3D models that are not only visual, but tactile as well. "You can provide much more useful anatomical information to surgeons, allowing them to do the right thing," he says. In addition to descriptive radiological reports, we can deliver something that is more comprehensive, with added value, he explains.

Dr. Swinnen continues by saying that 3D printing seems to be the next logical step for radiologists in delivering medical images. Artificial technology is approaching fast and it's an opportunity for radiologists to adapt their role and service, as well as quality of information.

Surgeons from different subspecialties, such as knee, shoulder, and hip orthopaedics, are also interested and becoming routine users of the technology for complex cases.

For the lab team at AZ Monica, two factors were essential for the start-up of the 3D lab: the combination of Materialise's software and a Formlabs SLA (stereolithography) 3D printer used in clinical framework. They made in-hospital medical-grade 3D printing a reality.

Working with dedicated and reliable tools

Having software you can rely on is important. Dr. Swinnen says, "There are not so many companies that deliver software that is medically cleared." Radiographer Sander Van den Wyngaert started on Mimics InPrint, a powerful segmentation tool for creating anatomical models in a very short time and preparing them for 3D printing. "I’m still learning," Mr. Van den Wyngaert says. "Now I can segment and create a 3D model of a wrist in 30 minutes and a fracture in ten minutes. InPrint is made so you can get along with it and learn it very fast.”

Photos courtesy of Sander Van den Wyngaert

A 3D center of excellence

Sustaining a successful 3D lab, another major goal of the lab's team, means building it within a complete work structure in the hospital. Although the 3D lab services are currently not covered by the national social security system, the team continues to invest in this innovation and aims to introduce internal financial models that need to be integrated into a recognized workflow. Finally, the team is working on providing solid data and evidence that 3D technology creates positive outcomes. "There's clear evidence of better results and fewer risks of complications," says Dr. Verstreken.

"I feel like it's unethical not to use it for many daily cases. If we have the technology available, I would feel very bad not using it," says Dr. Verstreken. A bold statement, but a sincere one.

The 3D lab team at AZ Monica is making progress in bringing 3D printing technology into the hospital. They started by taking it one step at a time.

3D-printed anatomical models for diagnostic use created with MIS/Mimics are not commercially available in the US, Australia and Canada.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.