CUSTOMER STORY

Point-of-Care 3D Printing Lab in India Enables Access to Personalized Treatment

3D printing has been established as a game-changing technology in the medical field. With the image processing and visualization capabilities of advanced software, it is now possible to convert the data from CT and MRI scans into digital 3D models and subsequently print physical parts using 3D printing. By implementing a 3D printing service in the form of point-of-care 3D printing into the Max Saket hospital, a group of specialized clinicians are now able to provide patients with more personalized treatments.

Virtual anatomical models are replicas of the patient anatomy and help provide the clinicians with a 3D visualization of the patient condition before surgery. The models can also be modified to create personalized medical devices such as surgical guides and personalized implants.

Since every patient anatomy is different, the 3D-printed models can be used for part of the initial clinician training in pathology and surgical techniques without putting patients at risk.

Setting up a point-of-care 3D printing facility in Max Saket

Dr. Choudhary, Principle Director & Chief with Max Institute of Reconstructive Aesthetic Cleft & Craniofacial Surgery (MIRACLES) at Max Super Speciality Hospital, Saket (Max Saket) was aware of the benefit and value of 3D-printed anatomical models for pre-surgical planning and was eager to adopt the technology to provide personalized treatments for his patients. He tasked Anatomiz3D, one of the leading medical 3D service bureaus in India, to create anatomical models, surgical guides, and personalized implants for complex surgeries.

However, engaging an external provider posed some challenges, such as the lack of accessibility, long lead time, and high cost. The process of conversion from CT images to 3D model, and subsequently 3D printing the model, required multiple interactions back and forth between Dr. Choudhary and biomedical engineers at Anatomiz3D. Due to the geographical challenge, the in-depth technical discussion and virtual simulation of the surgery would have to be conducted by phone or virtual meeting, which would not always be effective. In addition, the high cost of 3D printing and transportation from Mumbai (where Anatomiz3d is headquartered) to Delhi (where Max Saket located) was another reason which further hampered Dr. Choudhary from actively engaging the services with Anatomiz3D.

To overcome all these challenges and to make this technology the standard of care within Max Healthcare, Dr. Bharat Aggarwal, Director of Radiology at Max Saket, led the initiative and collaborated with Anatomiz3D to set up a point-of-care 3D printing laboratory within the hospital. The laboratory is managed by Anatomiz3D’s biomedical engineers, equipped with two 3D printers and Materialise Mimics inPrint software, which enables the conversion of medical image data (DICOM files) to 3D anatomical models.

The main benefits of point-of-care 3D printing

The point-of-care 3D printing laboratory has been up and running for ten months. The biggest advantage of having the lab in-house is how accessible it has made the technology to Dr. Choudhary and his colleagues who are also interested in personalized patient treatment. Whenever the surgeons need any kind of anatomical model or device, they can approach the biomedical engineers at the in-house 3D printing service in the hospital to discuss their queries. The in-house facility has also helped reduce lead time and cost for such services. The engineers create the design according to the surgeon’s requirements and deliver the final 3D-printed part within one to three days.

Within a short span of time since the establishment of the point-of-care 3D printing laboratory, the effect has already been significantly felt in the plastic surgery department. Before this, Dr. Choudhary placed orders for anatomical models with the external provider for a maximum of four cases over the last year. Within the first three months of the laboratory, Dr. Choudhary has ordered and used anatomical models for pre-surgical planning in 15 clinical cases. In each case, the anatomical models helped the surgeons plan their surgical approach, prepare their surgical instruments, and even support patient counseling. They experienced improved surgical outcomes, both aesthetically and functionally, and reduced operating time.

Challenging cases supported by Materialise software and 3D anatomical models

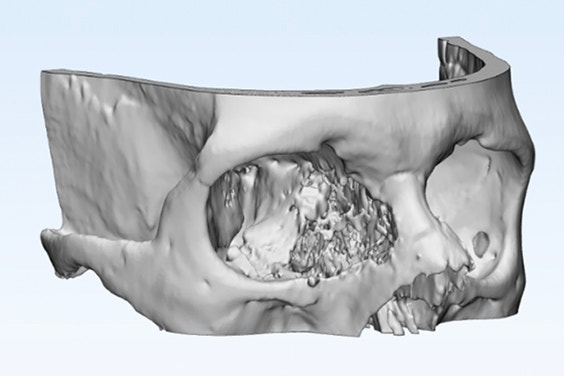

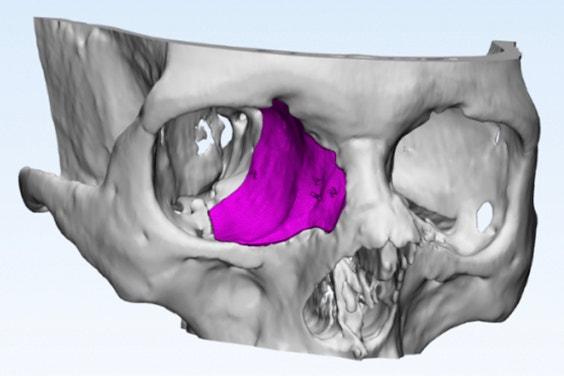

One of the more challenging cases performed by Dr. Choudhary involved a tumor in the orbital region. The corrective procedure involved removal of the tumor, affected tissue, and reconstructing the missing area with bone graft. It is a very challenging procedure, because there are a number of minute structures in the orbital region that cannot be clearly seen during surgery, such as the optic nerve and blood vessels. Also, achieving a symmetrical reconstruction with good aesthetic output is crucial. Thus, getting the right shape of the graft and fitting it in the right position becomes extremely important. 3D printing supported the successful outcome a great deal.

Photo credit: Anatomiz3D

From the patient’s CT scan, an anatomical model was created to help the team of doctors to better visualize the defect area in 3-dimensional space. Using the software, the tumor region was cleared out, and the healthy side of the skull was then mirrored and used to accurately simulate the reconstruction of the defect side. Based on this, a reconstruction template was created. Dr. Choudhary believes that the anatomical model helped him better prepare for the surgery, while the reconstruction template was used to cut the bone graft into the right shape. This led to a more precise fit and better aesthetic reconstruction. Apart from the improved surgical outcomes, this also helped save almost one hour of operating time.

Outsourcing medical 3D printing to other healthcare institutions

Apart from plastic surgery, the point-of-care 3D printing lab has also attracted interest from other departments, such as orthopaedics, neurosurgery, cardiology, oncology, pulmonology, and even obstetrics and gynaecology. In addition, the services of the point-of-care 3D printing lab are not only limited to Max Saket, but have also been opened to all Max hospitals across Delhi with great response.

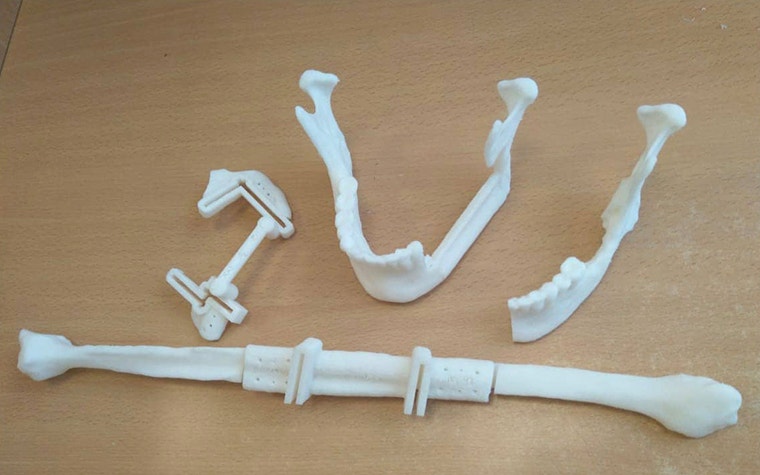

An example of this is a case of mandible reconstruction using a free flap fibula, performed by Dr. Pawan Gupta and Dr. Vipin Barthwal at Max Vaishali. The patient had a mandible tumor, which needed to be excised and reconstructed with the fibula bone. This is a challenging procedure, as it requires removal of the mandible region and then accurately reconstructing it with the correct length and shape of the fibula bone, achieving correct aesthetic and functional output.

In this case, an anatomical model of the defect mandible and the fibula was 3D printed to give the surgeons a better visualization. The surgery was then simulated on Materialise Mimics Medical software, including resecting the defect region of the mandible, mirroring the healthy anatomy to guide in reconstruction, and osteotomy of the fibula to fit the reconstruction region precisely.

Based on this, personalized cutting guides were designed to guide the surgeons in achieving the pre-planned cuts in the operation theater. This helped them resect the mandible tumor with ease and perform a precise osteotomy of the fibula to fit the resected portion of the mandible well. The surgeons were very pleased with the result, having achieved the correct shape of the mandible, with both aesthetic and functional output. The surgeons also mentioned that this helped reduce surgery time by almost two hours.

Anatomical models of the diseased mandible, fibula, and reconstructed mandible, along with the mandible resection guide and fibula osteotomy guide.

Looking towards the future with point-of-care 3D printing facility at Max Saket

Although 3D printing as an in-house service in Max Saket is still in its infancy, many innovative institutions have been blazing a path. For Max Saket, it’s the first step of an exciting journey towards advancing personalized patient care. Dr. Choudhary and Dr. Aggarwal truly believe that the point-of-care 3D printing laboratory will not only help improve surgical outcomes and reduce operating time but also provide doctors with the freedom to perform cutting-edge research and develop new therapies for future patients. In addition, 3D-printed models are a valuable training asset and can be used to teach the next generation of doctors in a more efficient and productive way.

L-101206-01

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.