CUSTOMER STORY

How a Modular Testbed Helps Medical Device Developers

During the development of new 3D printing medical device, as well as in scientific research, it is of the highest importance to test and validate results. At the Bio-Inspired Technology research group of the Delft University of Technology in the Netherlands, engineer Awaz Ali has designed and developed a new multi-steerable catheter, with snake-like tip motions and complex curves, for complex cardiac interventions. The ability to create such a device with improved maneuverability inside the highly dynamic environment of the heart could allow more complex cardiac procedures to be performed through a transcatheter approach.

Awaz wanted to test its steering possibilities inside a realistic heart model and vasculature. For this purpose, bench-testing seemed the most appropriate, as a testbed allows pathway analyses and isn’t subject to any changes or deformations.

From design phase to test phase

Awaz’ goal is to investigate whether improved steerability of interventional catheters could enhance complex trans-catheter cardiac procedures. Therefore, under supervision of her promotor Prof. Paul Breedveld, she designed a multi-steerable catheter prototype which was then manufactured by Remi van Starkenburg, precision technician at the Electronic and Mechanical Support Division of the Delft University of Technology. This catheter, called the Sigma Catheter, can adopt a variety of different angles and curves by bending its tip, including S- and Z-shaped curves and multi-planar curves. Once the catheter was designed and functional, the next challenge was to prove the prototype’s added functionalities without testing it in animals already.

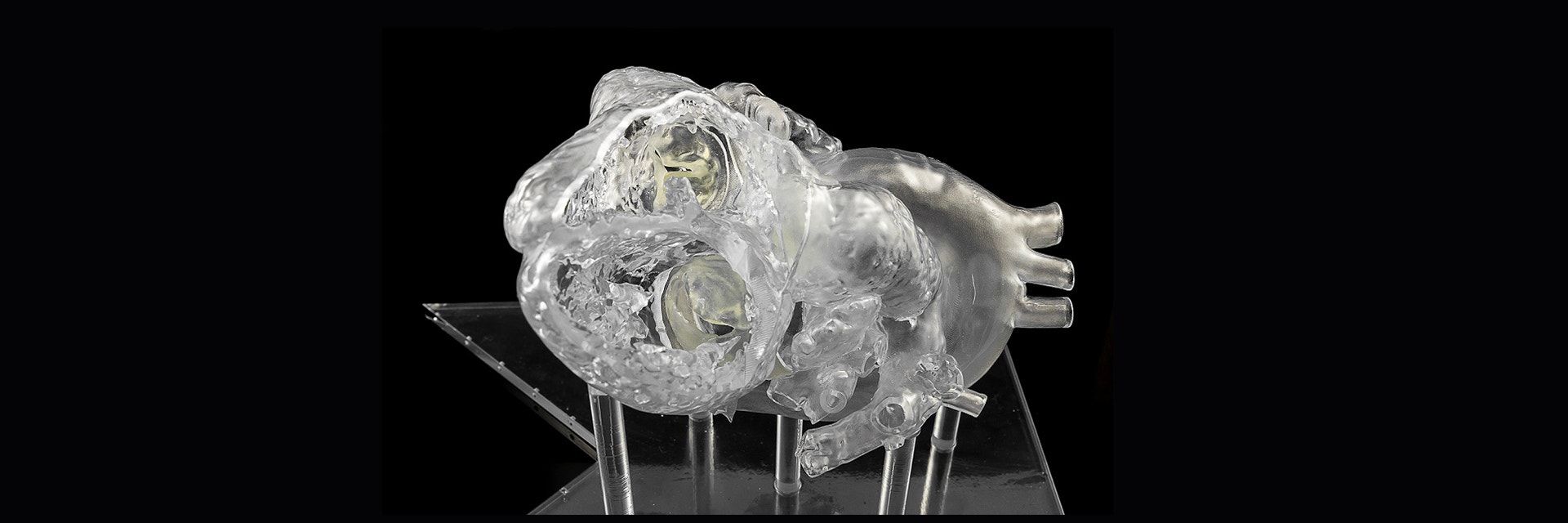

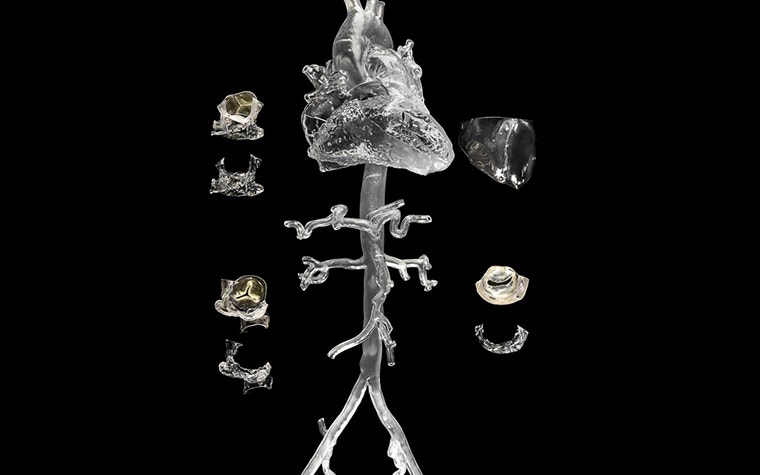

In order to test the catheter’s uses in different steering modes and along different anatomic pathways, the researcher wanted to have a highly realistic and transparent testbed. This is where Materialise’s modular heart model proved to be a solution: the model is based on real patient data and has correct anatomic dimensions. The testbed is also transparent, so that the test subjects can get visual feedback when maneuvering the catheter inside the heart model.

“Awaz testifies: “The testbed incorporates highly detailed anatomic structures such as beautifully mimicked heart valves and papillary muscles on the ventricular wall. Another main benefit was the fact that we could add as many additional requirements and specifications as we liked. A few examples are the following: a region for the atrial septum, multiple windows in the heart that can be opened and closed, and locally smoothened surfaces inside the heart.””

Prototype testing with a modular 3D-printed benchtop model

Awaz is currently preparing an experimental set-up to test the catheter and compare its functionality in different regions of the cardiovascular system. The set-up consists of a 3D-printed modular heart model and the catheter prototype with its multiple steering modes, which will be controlled inside the model through three different pathways. A sensor is also incorporated in the catheter, to track the path it will follow inside the heart model, and a number of electrodes will be placed inside the heart model to detect contact between the catheter and the heart model.

During the test, Awaz will measure the time it takes for the test subjects to complete a certain task and analyze the pathway of the catheter while the subject performs that task. This will allow her to identify which anatomic regions in the cardiovascular system require a higher degree of catheter maneuverability. Additionally, the testbed can be used to identify factors such as physical and mental loads in performing the tasks inside the model.

Based on the outcome of this experiment, the catheter will be further improved for cardiac applications. After this, the aim is to test the catheter in a real setting using a beating heart. Parallel to these activities, Awaz will focus on a number of cardiac procedures for which novel tools have been designed as well. The promising researcher concludes:

“I think 3D-printed models offer a completely new method for testing our instruments, allowing them to be tested in scientifically valid models which can be easily extended with additional requirements.”

Share on:

Biography

About Ir. Awaz Ali

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.