INTERVIEW

Meet the Users of Materialise Magics: The Renato Archer Center

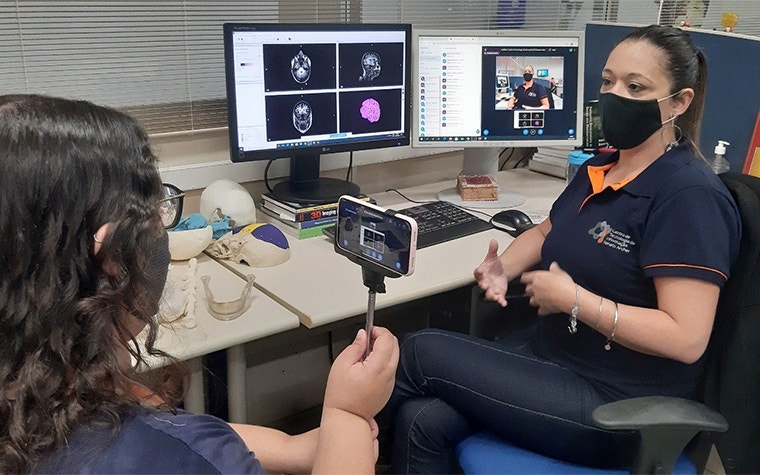

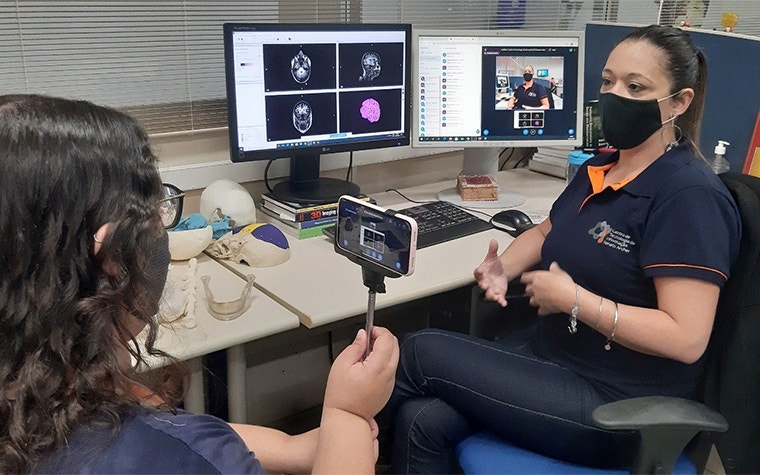

Magics is used in a wide range of industries, and we love hearing from all of our partners about how our software makes a difference in their work. In this interview, we spoke with AM champion Amanda Nunes, former Project Researcher at the Renato Archer Center, to learn more about their use of Magics and her thoughts on the power of additive manufacturing (AM).

What does the Renato Archer Center do, and what is the role of AM?

Renato Archer is a government agency within the Ministry of Science and Technology. In my role, I worked in the medical department of our 3D printing lab and supported doctors and surgeons from Brazil's national health system. Our pilot project was helping surgeons plan for all kinds of surgeries, no matter the field or part of the body. We design and print personalized anatomical models for surgeons to successfully plan their operations.

The center focuses on research and innovation, so our work is more complex. When doctors have a particular request and the right planning product isn't available, they come to us for a custom solution that will help them better prepare for surgery. The benefits of this type of program are immeasurable. There's a reduction in surgery time, a reduction in patient recovery time, an increase in the number of surgeries per unit since the doctors can operate more efficiently, and many others.

Software is undoubtedly one pillar of this process that — together with additive manufacturing, specialized engineering, and medical personnel — can transform the health sector.

How does Magics support the center's projects?

When I started at the center in 2008, we were already using Magics, and I used it for all of my surgical planning. We first digitally reproduce the anatomy, such as kidneys, lungs, and hearts, based on DICOM images, then segment it. After that, I use Magics for the modeling, editing, and repairing, then send the files to the printer's software for slicing. Plus, I was always happy to collaborate with the Materialise team here in Brazil. They're a great help!

How did your use of additive manufacturing evolve over the years?

Since I started at the Renato Archer Center, we grew from using just laser sintering, fused deposition, and PolyJet. We added biomaterials, selective laser melting, electron beam melting, and software that plans machine capacity and generates support structures.

And personally, using software like Magics that guides you through customization and simplifies the process has helped me a lot in several other sectors where I work. Currently, I'm an instructor at SENAI, the National Service for Industrial Training, where I help prepare students for the industrial workforce. I train them in management, administration, and logistics. And thanks to my experience in 3D printing, we've acquired some 3D printers and I can teach my students the practical details of 3D printing.

How do you envision the future of 3D printing?

As an educator, I'm very glad that I can encourage my students to reassess the traditional ways of thinking about manufacturing — to break down paradigms and create a new culture where we work with innovation at the top of mind. I try to get my students to be more innovative regarding museum displays or forensic reconstruction, for example, where 3D printing's potential could make a significant impact.

I used to live in São Paulo where 3D printing is big, but it's just beginning here in Rio Grande do Sul. At the Renato Archer Center, we helped many people and used 3D printing in infinite ways, but that's just not the mindset here yet. For instance, say you ask an engineer to build a gear. Typically, they immediately start thinking of methods they're used to and find reliable, like a lathe. They don't think 'I can build differently, more customized, with 3D printing.' We need to encourage people to think of 3D printing as an option from the beginning. There's so much resistance because of misconceptions like long build times and high costs, but there are so many more possibilities waiting for us with 3D printing.

It's also a passion of mine to help encourage more women to enter our field, so I'd love to see that in the future. I'm an ambassador with Brazil's Women in 3D Printing group, which gives me a lot more opportunity to educate others in the technology.

L-103360-01

Share on:

Biography

Amanda Nunes

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.