EXPERT INSIGHT

Want to Become a ‘Factory of the Future 4.0’? Don’t Go It Alone

The industrial landscape is going digital. By 2020, PwC expects as many as 64% of manufacturing factories to use connected sensors and the number of factories using 3D printing to double. Meanwhile, Deloitte warns that becoming a smart factory requires “more than just a set of connected assets,” pointing out the importance of factors like workforce engagement and sustainability. So where are we today? For Materialise, the emergence of Factories of the Future is not a phenomenon we’re waiting for. It’s a vision we’re realizing today. And last week, at an awards ceremony in Belgium, we were proud to be awarded the ‘Factory of the Future Label 4.0’ by industry platforms Agoria and Sirris after a rigorous selection procedure.

But we’re not going the distance alone. Read on to discover why you can’t be a Factory of the Future in a vacuum.

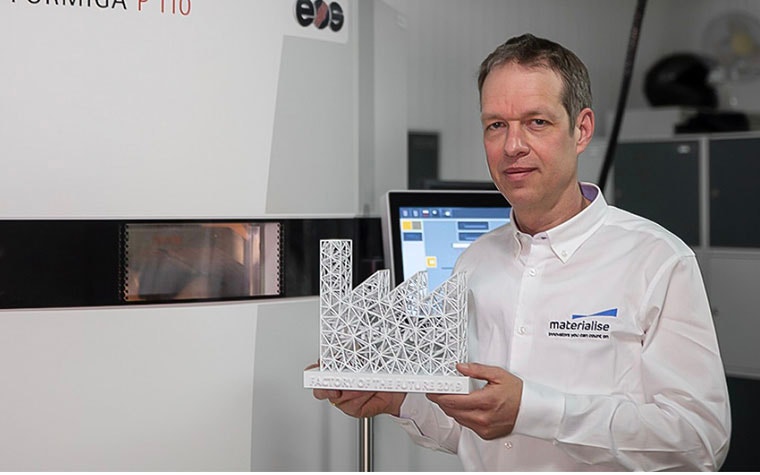

“Achieving the Factory of the Future label is extremely exciting. For two years now, we have been advocating the role of additive manufacturing in enabling Industry 4.0. The assessment, because it comes from an independent observer, is tremendously valuable in reiterating that 3D printing is a crucial component in the Factory of the Future: and, moreover, that Materialise is a frontrunner when it comes to technological advancement. ”

— Bart Van der Schueren, Chief Technology Officer at Materialise

7 transformations for Factories of the Future

Agoria and Sirris, trade associations for the technological industry in Belgium, are developing a methodology to identify Factories of the Future and eventually support companies in transforming their manufacturing operations to join that league. Last year, Agoria received a grant from the European Commission to roll out their methodology at the European level. Towards the end of 2018, a team of Agoria and Sirris auditors, along with industrial specialists, carried out an intensive assessment of Materialise, focusing particularly on the Manufacturing division and its additive manufacturing production unit.

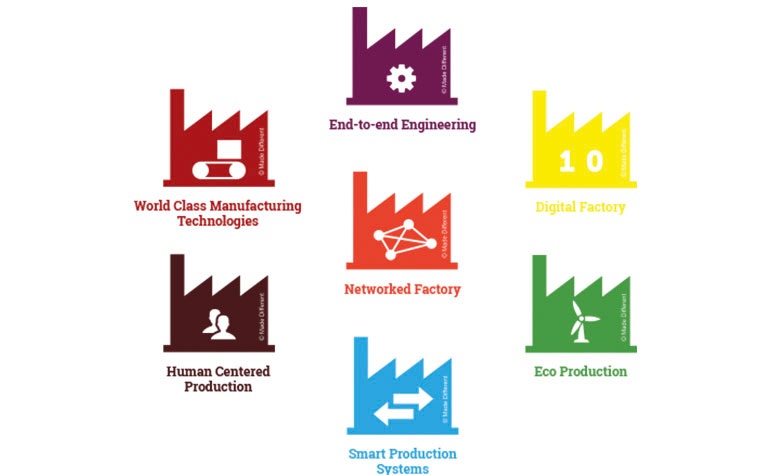

In order to become a Factory of the Future, Agoria’s team determined that a manufacturing company must undergo seven transformations in areas as diverse as technological advancement, workforce engagement, and inter-company collaboration.

7 transformations to become a Factory of the Future (right) and the Materialise team at the Factory of the Future 4.0 award ceremony (left)

“If you want to be a Factory of the Future, you don’t work in a vacuum”

Among the criteria where Materialise ranked particularly highly are networking and a collaborative approach (becoming a Networked Factory).

“If you want to be a Factory of the Future, you don’t work in a vacuum. Materialise has always been outspoken in its support of co-creation and open solutions. This year we’re placing a major strategic focus on enabling interconnectivity, which I see as one of the biggest trends in 3D printing in 2019. This is what makes us Materialise: we’re not into just producing parts. We’re taking a holistic view of the ecosystem and the role our core competences can play in adding value to it, no matter whether the products in question are industrial or medical,” explains Bart Van der Schueren.

In recent months, Materialise has announced strategic initiatives with major players both within the 3D printing industry and outside of it. Collaborating with leading 3D printing machine manufacturer Stratasys enables hospitals to adopt point-of-care 3D printing. A partnership with chemical producer BASF focuses on promoting an open-market model in the industrial 3D printing arena. Taken together, these and other strategic partnerships highlight Materialise’s belief in collaboration as the key driver of innovation: and not the converse.

“That same belief is why I would love to hear from companies who want to realize their own Factory of the Future. We’re there already: and we’re happy to share our expertise with partners to help realize a digital manufacturing future together,” concludes Bart.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.