EXPERT INSIGHT

4 Ways AM Helps You Cut the Total Cost of Ownership of Your Products and Create More Complex, Affordable Parts

Money makes the world go around. Money doesn’t grow on trees. Money talks. All these common phrases illustrate the significance of money. And with inflation, interest rates, energy prices, materials, and goods and services all increasing, looking after your hard-earned capital has never been as important. Businesses are feeling the brunt of these rises, and consumers are feeling the pinch, too. That’s why finding ways to reduce manufacturing costs while creating complex but versatile products is a smart way to boost revenue and gain a competitive advantage. Thankfully, additive manufacturing (AM) is an excellent way to achieve all these things.

AM is making it easier for manufacturers to lower the total cost of ownership (TCO) of their products by incorporating 3D printing into production workflows. Plus, companies are increasingly using AM to produce unparalleled designs at lower costs. This is a major benefit, as the cost per part is influenced by the part’s complexity. And geometries such as moving components, cavities, and lattice structures are often more complex than traditional designs, which can increase production costs. However, AM is the perfect solution to reduce part complexity, streamline production workflows, and create extremely complex parts more easily.

Cost and complexity (C&C) often go hand in hand, factoring into over half of manufacturers’ business decisions concerning the use of AM. Additionally, technical drivers and opportunity cost are pivotal in determining whether a manufacturer uses or scales its AM production. Thankfully, we can show you why, on many occasions, 3D printing is the perfect industrial method for taking up the C&C challenge!

Here are four ways 3D printing and AM software solve the C&C problem and some solutions to cut costs in your production processes.

1. AM reduces TCO and creates added value

The automotive industry is a prime example of an area that’s benefited from AM. Companies like Volvo, Toyota, BMW, and Volvo have used RapidFit’s innovative, modular 3D-printed solutions for years. Their automotive inspection and production tooling helps businesses increase efficiency, reduce risk, and meet quality standards. For example, their modular measurement and checking fixtures can result in up to a 50% lower total cost of ownership due to cost-efficient modifications and fixture versatility, and the same percentage applies to their sophisticated cubing systems. But automotive isn’t the only industry leveraging AM to deal with C&C. Companies in the cycling industry are now more aware of AM’s capabilities as well.

Pinarello, an Italian bike manufacturer, collaborated with our Metal Competence Center in Bremen, Germany, to help them produce their lightweight racing bike, Dogma F. Using our 3D printing services, design expertise, and tailor-made workflows, Pinerallo managed to cut the weight of the bike’s seat clamps by 42.5% while meeting their objective of cost, quality, speed of production, and the number of units manufactured. Our software experts created a custom printing parameter set that sped up printing time, met the required material properties, and made the project feasible by optimizing costs, keeping them as low as possible.

By optimizing the design and streamlining production processes, they ramped up their part delivery to 2,000 pieces every three weeks. The additive nature of AM allows manufacturers like Pinarello to produce parts with more design freedom, reducing material consumption, while improving manufacturing efficiency and TCO. This is especially apparent if design for additive manufacturing (DfAM) and AM software are used in tandem, which is usually the case in the aviation industry.

The GE9X is the largest jet engine in the world and was developed for Boeing’s next-generation 777X jets. It’s a prime example of how DfAM and AM software can provide tangible benefits to a company’s manufacturing process. Avio Aero, a company that’s part of GE Aerospace, 3D printed the engine’s fuel nozzle and air turbine blades for the aircraft. 3D printing reduced the number of parts and the nozzle's weight, streamlining the piece's complexity while boosting its efficiency.

However, the turbine blades were particularly important, as they became the driving force behind the 10% gain in GE9X’s fuel efficiency, resulting in the most fuel-efficient engine GE Aerospace has ever produced.1 It’s a significant achievement because fuel accounts for around 22% of an airline’s operational expenses: a substantial gain.2

Between 2022 and 2023, it’s estimated that they produced around 60,000 certified blades. Certified 3D printing at such an industrial scale requires maximum traceability, quality control, and repeatability — while ensuring high throughput and efficiency in the machine’s operation time, waste minimization, and cost control. That’s why they used our robust and integrated AM software solutions to scale their parts and AM business efficiently, reliably, and securely.

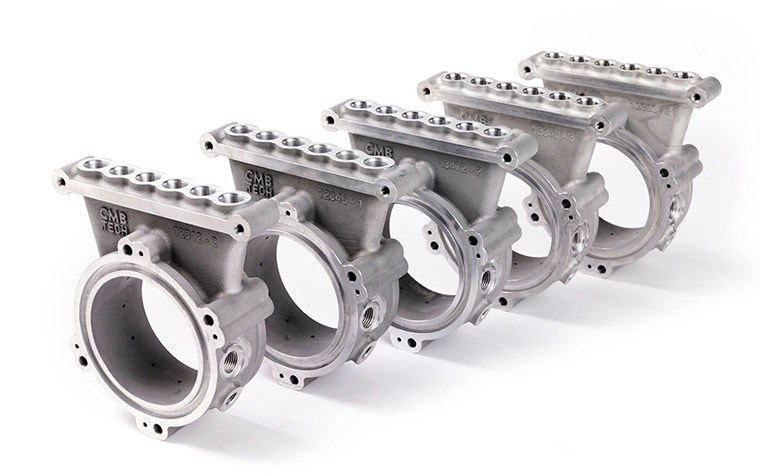

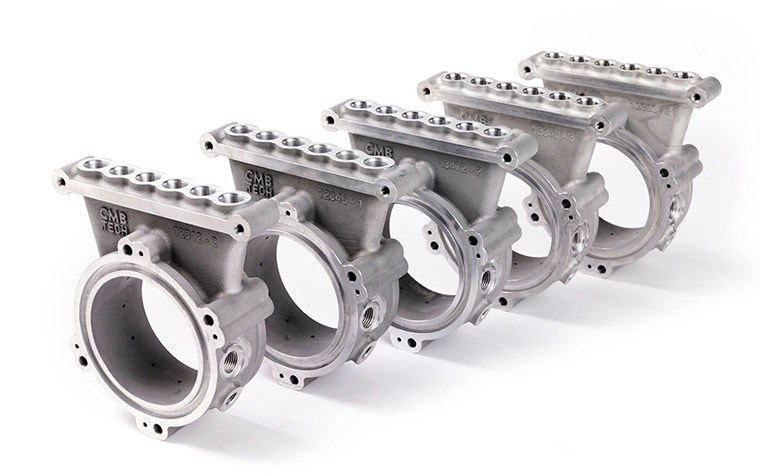

CMB.TECH is another manufacturer that used AM’s design freedom to revolutionize their engine. Their hydrogen-diesel dual-fuel combustion technology, designed to decarbonize large marine and industrial applications, uses a 3D-printed injection ring. And, as the aluminum ring is printed with selective laser melting (SLM) to match the materials preferred by most engine manufacturers, it fits right into its environment.

The result? Metal 3D printing proved to be approximately 25% cheaper than casting, and the lightweight part weighed only 654 g — the equivalent of a loaf of bread.3 Additionally, the simplified system reduces CO2 emissions by up to 80% in traditional diesel engines, depending on the application and the circumstances.

As demonstrated by the examples above, 3D printing helps companies produce complex parts more cost-effectively than traditional manufacturing techniques, or reduce TCO and operational costs throughout a business’s production. Not to mention offering other advantages, like improving sustainability, efficiency, and design flexibility. But that’s not all; the benefits are almost endless! AM is an effective way to slash inventory costs and simplify supply chains, too.

2. AM reduces the need for extensive stock inventories

Eyewear is another industry where margins are tight and costs are under constant pressure. Eyewear is a challenging environment, especially for independent brands. Due to fast fashion, consumers expect the trendiest clothing and apparel quickly, cheaply, and in various sizes. At the same time, eyewear businesses need to produce frames in bulk and at speed to meet consumer demand while keeping costs as low as possible.

This balancing act is difficult for start-ups and smaller eyewear brands that want to offer customers high-end but affordable frames. Failure to meet this balancing act leads to a large and often expensive surplus of stock. Simultaneously, the consumer mindset is shifting. Shoppers are becoming more conscious of how and where fashion products are being produced and more aware that they should be made sustainably.

However, AM’s speed and versatility make it the ideal solution. Digital, on-demand manufacturing offers companies the flexibility and design freedom to print quickly, anywhere, and more sustainably — providing corporations with the ultimate tool to slash costs and aid business agility

Entrepreneurial fashion companies, particularly in eyewear, are using 3D printing to solve C&C because they face two ongoing dilemmas based on the fast fashion model. The first is keeping up with consumer demand. The second is mitigating risks that come with launching new designs. Over-production, high start-up costs, and wasted material are common factors with traditional manufacturing methods that financially impact eyewear companies, with the hardest hit being up-and-coming brands. Meanwhile, ignoring the environmental impact can damage a brand’s reputation and, on a wider scale, increase global greenhouse gas emissions responsible for climate change. The fashion industry accounts for 8 – 10% of global emissions.4

That’s why Odette Lunettes, a Belgian brand with a growing fanbase based on their unique collections of designer frames, decided to use 3D printing to balance the public’s desire for fast fashion with sustainable business practices, resulting in remarkable results.

Their innovative eyewear collection, Odette Lunettes X Tom Boonen, marries sustainable material, 3D printing efficiency, and DfAM ingenuity to create personalized, sustainable eyewear that’s simply not possible without AM.

3D printing allowed them to innovate, experiment, produce faster prototypes, and create the final frames more efficiently than other methods. They used 3D printing to reduce material wastage and on-demand manufacturing to make smaller batches, decreasing the risk of over-production and unsold stock. In effect, AM enabled them to cut lead times, time-to-market, and costs to improve their product’s performance. However, eyewear and fashion are not the only industries that rely heavily on balancing stock levels. The aerospace industry also can benefit from AM’s on-demand capabilities to produce spare parts and ease supply chain disruptions.

3. AM mitigates supply chain disruptions

Contrasting the smaller consumer items found in the fashion industry are aerospace companies’ larger commercial items. These range from passenger jets to cargo aircraft. Manufacturers like Boeing and Airbus produce complex multi-million-dollar machines made up of thousands of parts. Any delay in commercial aircraft during development or while undergoing maintenance can cost millions in lost revenue. This leads airline manufacturers with an on-going dilemma: should they keep inventory management in-house for more control or outsource it to an overseas, third-party service provider that will store and ship the parts to them, but may run into production or transportation delays which could disrupt their overall supply?5 AM solves this quandary for them, due to on-demand digital manufacturing. Because of this unique manufacturing technique, 3D printing for aerospace is beginning to really take off.

Our collaboration with Proponent, the largest independent aerospace distributor, and Stirling Dynamics, an EASA 21.J-certified Aerospace Design Organization, aims to accelerate the adoption of 3D printing for cabin and non-critical parts. This partnership aids the aviation market and mitigates supply chain risk.

By identifying, certifying, and providing on-demand 3D-printed cabin solutions for OEMs, airlines, and MROs, our relationship will lower the hurdle to integrating such solutions. Furthermore, this exciting partnership will also increase the possibility of 3D-printed solutions being incorporated into after-market supply chains.

Additionally, Expleo, an EASA-certified design organization, has made flight-ready non-critical spare parts smarter with AM. They developed a replacement part/latch that can strengthen a Boeing 737’s dado panels against future breakages and remove the need to replace the entire panel. Not only would airlines save substantial costs by not having to replace entire dado panels, but they could also vastly extend the lifespan of existing panels. This is safe in the knowledge that the repaired panels will be stronger and less likely to break than ever before.

The company even extended this out-of-the-box thinking to create added-value replacement and one-off spare parts more easily with the Dado repair kit. We worked with them to translate the novel design into 3D-printable files that could be printed at our certified facility — orienting and connecting the parts in such a way as to meet the stringent structural reliability and safety requirements for certification. At the same time, this solution minimizes waste, ensuring the parts could be easily and safely separated and used.

These two ingenious and practical ideas help aerospace OEMs reduce waste, minimize lost revenue due to additional maintenance, and make them more resilient to supply chain disruptions.

Innovations such as the on-demand digital manufacturing for spare parts and products like the Dado repair kit, are massive breakthroughs. Supply chains have experienced huge disruptions over the last few years — so easing them will keep the global economy ticking, consumers happy, and businesses thriving. With such solutions, airlines can ensure that their planes remain operational and in the air, instead of the tarmac. Additionally, as we live in a 24/7 society, it’s imperative that manufacturers keep assembly lines rolling and products moving — and that’s the final way AM can reduce a business’s C&C risk.

4. AM reduces production downtime

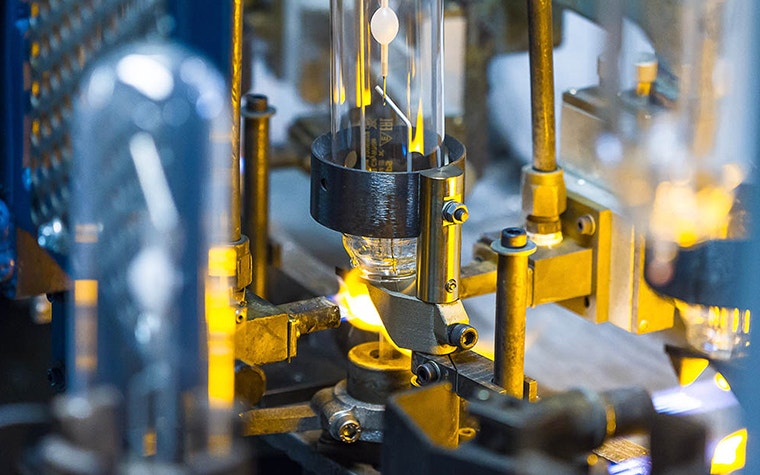

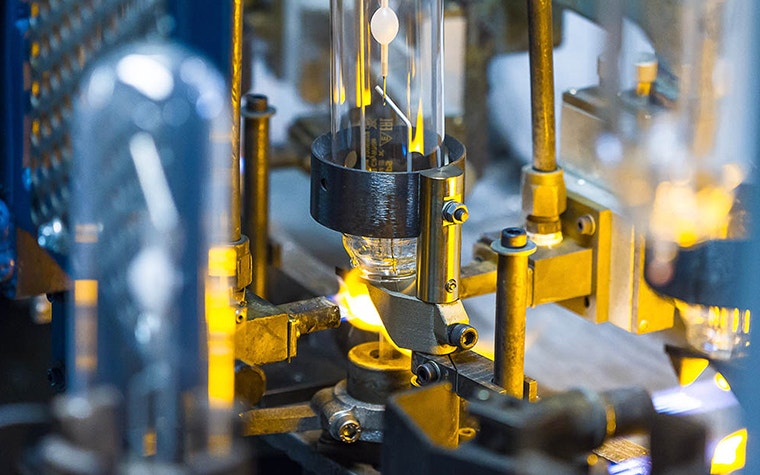

Companies need to maximize cash flow to keep the lights on and the chain of production moving, figuratively speaking. But in Signify’s case, they used AM to make sure both were maintained, literally. Signify (previously known as Philips Lighting) came to us to solve a problem on their shop floor. Could the benefits of 3D printing — such as reliability, efficiency, and rapid prototyping — be applied to improve certain components on their assembly line prone to persistent part failure?

The answer was a resounding yes; AM has helped significantly reduce their operational costs. The collaboration resulted in the reinvention of a lamp holder bracket and suction gripper that have functioned continuously for four years without breaking once, realizing cost savings of around €89,000 a year.

AM also cut down the time their operators needed to replace these parts on the line, and because they have access to ‘digital spares’ that can be printed in just ten days, they can save space in their facility. AM provided operational benefits to machines and workers on the factory floor and inspired the team to look for other ways to bring efficiency to different areas of the company. As a result, the team (re)designed other pieces, such as a new burner that combined several pieces into a single 3D-printed shape, improving the company’s efficiency even further.

For Signify, AM kept the production conveyor belt running on their shopfloor, while putting the gears in motion for new ideas from their production team, shining a light on new opportunities and wins that could greatly benefit the organization.

More cost-effective parts, smaller stock inventories, and shorter downtimes. But is that all?

AM is clearly a viable cure for companies looking to reduce TCO and realize cost savings across the board. Applying AM to functional, complex, and spare parts is one way — along with using it to build more robust assembly lines to reduce production downtime and increase operational efficiency. And it’s also clear that 3D printing is an obvious solution for companies’ wanting to achieve their C&C ambitions. But are the benefits listed above the only advantages that AM offers? (Here’s a hint: they aren’t!)

In our next article, we’ll explore a few more ways 3D printing and AM software can slash labor costs, save time, and shrink your scrap — with the help of AI, automation, and in-situ monitoring. Stay tuned for part two!

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.