INTERVIEW

Collaboration at Queensland University of Technology Gives Students a Head Start in Their Careers

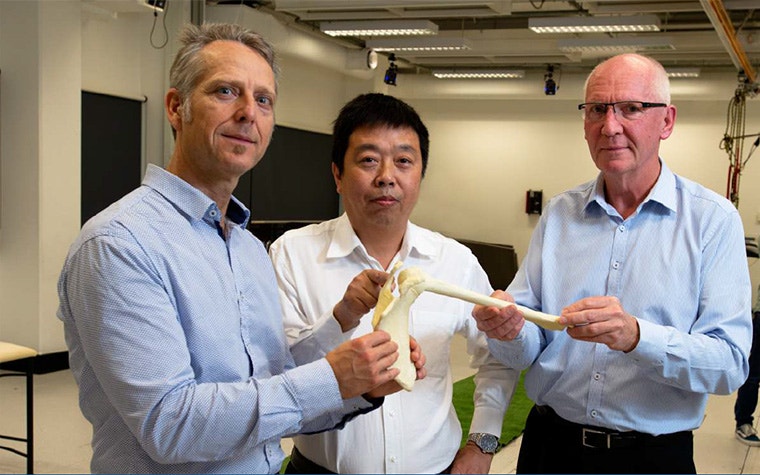

Impactful innovation results from close collaboration, and we're noticing great strides in personalized care stemming from partnerships initiated by universities. We spoke to members involved with the Queensland University of Technology (QUT) and Joint Biomechanics Training Centre to learn how their programs help students advance in their careers. Read on for insights from Professor Peter Pivonka (Professor and Chair of Biomedical Engineering at QUT, Deputy Director of Joint Biomechanics), Mr. Marco Branni (QUT graduate and Biomedical Engineer at medical device company Akunah), and Dr. Maxence Lavaill (Post-doctoral fellow in computational biomechanics at QUT).

Can you share an overview of what the Joint Biomechanics Training Centre does and what your role is?

Professor Pivonka: I am the Deputy Director of the Centre and responsible for all aspects related to research and training. The Centre connects leading researchers, end-users, and industry partners to form a highly skilled multidisciplinary workforce that will transform the orthopaedic industry. At the Centre, we have 14 higher degree by research (HDR) students, five postdoctoral fellows, and a large number of affiliated HDR students and researchers. A critical part of my role is identifying suitable hard and soft skill-based workshops to build the expertise and skill sets of our students and early career researchers, who are the next generation of Australia’s biomedical engineering workforce.

Collaboration is a key priority at the Centre. Why is it so important to connect researchers with end-users and industry partners?

Professor Pivonka: The primary focus of our Centre is to provide patient-specific solutions for shoulder pathologies. To do this, we have assigned four programs that address different issues related to the journey of a patient: In-Silico Simulations of the Shoulder Joint for optimal implant design and rehabilitation training; Robotic Assisted Technologies for the precise imaging of tissues and positioning of implants; Tissue Engineering Solutions to regenerate compromised tendon tissue; and Novel Rehabilitation Programs and Technologies to accelerate patient recovery. Connecting with the surgeons executing shoulder arthroplasties, researchers from various programs, and the respective industry partners is essential to create optimized patient outcomes.

Dr. Lavaill: Biomechanics is, by definition, a transdisciplinary field involving scientists, engineers, manufacturers, surgeons, nurses, and more. It is essential to gauge the interests of all stakeholders and work together to make the research meaningful and impactful for everyone, most of all for the patients.

What are some examples of success stories achieved at the Centre?

Professor Pivonka: One example is the Queensland Unit for Advanced Shoulder Research (QUASR) at QUT, which began as a small group of enthusiasts, including surgeons and biomechanists, wanting to create better solutions for patients with shoulder problems. When we developed the proposal for this group, we realized that we needed a large multidisciplinary approach as opposed to the typical compartmental procedures to create novel and innovative solutions for patients. We approached a number of industry partners that were intrigued by this grand vision, and all provided support for the proposal.

We also have several other exciting projects in the works that use cutting-edge technology, such as robotics and simulation. For example, we're working on the development of statistical shape models of the shoulder complex to predict shoulder kinematics, which will provide new insights into choosing a prosthesis based on its fit with the shoulder anatomy.

What tools do you use at the Centre and what value do these tools bring?

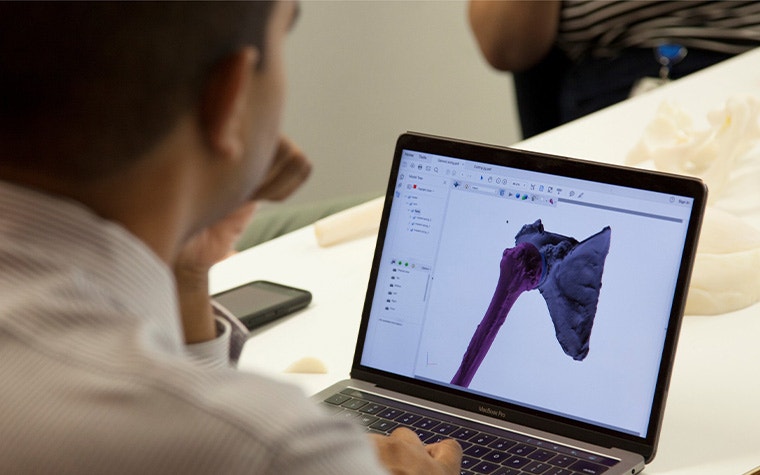

Dr. Lavaill: We first collect images from our orthopaedic surgeon partners' clinical practices. We then use the Materialise Mimics to anonymize and segment bones and muscles. Segmented bones can then be imported into 3-matic to undertake measurements and create subject-specific jigs or cutting guides for biomechanical experiments. Segmented bones and muscles can also be used for computational modeling studies to further develop patient-specific musculoskeletal models capable of computing muscle and joint forces or finite element models to understand stresses and strains inside bones and implants.

What value does this type of education offer graduates when entering the workforce?

Professor Pivonka: Graduates from the Centre have acquired a broad knowledge of the different fields involved in treating patients with joint problems, including biomechanics, robotics and imaging techniques, tissue engineering, and rehabilitation. Furthermore, our graduates have developed excellent communication skills to facilitate collaboration between surgeons, academia, and industry.

Dr. Lavaill: Graduates can choose precisely where they want to work thanks to the experience provided by the Centre, and they have the expertise and network to undertake transdisciplinary collaborations. Thanks to our cooperation with Materialise, graduates have also acquired thorough experience using state-of-the-art software for medical image processing. This is a great advantage when entering the market.

As an academic, when do you feel successful in your career?

Professor Pivonka: There are a few key points when I feel successful. First, while teaching a class or a workshop, the moment students say they finally understand a complex topic, it’s great feedback to receive. In terms of research, when you write papers, present them at conferences, and hear positive responses from leaders in that field, you know you’ve done something good. And finally, at the university level, you have feedback from your fellow faculty members. If you hear from colleagues or the head of the school that you seem happy in your role, that’s another type of success.

Mr. Branni, you were involved with these collaborative projects before graduating. What did you work on at QUT?

Mr. Branni: During my time at QUT, I was involved in various numerical and experimental projects focusing on bone mechanics. My PhD research specifically looked at the material and mechanical behavior of trabecular bone, focusing mainly on the proximal human femur. I used a range of techniques, including segmenting micro-computed tomography images to develop finite element analysis and investigate the mechanical properties and behavior of trabecular bone.

Additionally, I was also involved in several projects related to human shoulder mechanics. One notable project involved comparing two common procedures for reverse shoulder arthroplasty to evaluate their performance under cycling loads. For this project, we used 3D-printed scapulae to conduct mechanical tests and gather data on the performance of the procedures.

What is your role now?

Mr. Branni: I recently joined Akunah in Brisbane as a Senior Biomedical Engineer where I'm part of the R&D team. Akunah is a medical device company dedicated to developing software and mobile applications to streamline the personalization of orthopaedic care and data-driven solutions. In my role, I have the privilege of leading and contributing to a range of projects aimed at developing innovative and personalized medical devices and technologies.

At Akunah, my day-to-day responsibilities include conducting research, performing testing, and collaborating with others to ensure our products meet the highest safety, efficacy, and quality standards for patient-specific solutions. These projects challenge me to use my technical and problem-solving skills in new ways and have given me a great opportunity to work with a talented and dedicated team of engineers and clinicians. I'm thrilled to be a part of the Akunah team, and I look forward to continuing to contribute to the development of cutting-edge medical technologies to improve the lives of patients around the world.

What takeaways from QUT and the Centre help you most in your current role?

Mr. Branni: At QUT, I had the opportunity to work closely with clinicians, engineers, and scientists with diverse backgrounds and expertise. This collaborative approach helped me better understand the clinical needs and challenges associated with medical device development and exposed me to new ideas and techniques. The culture of innovation and collaboration at QUT inspired me to think creatively and approach problems from new angles with a focus on translating research into real-world solutions. It's an essential mindset to bring to my work at Akunah, where we're constantly looking for new and better ways to meet the needs of patients and clinicians.

Working with industry-leading software such as Mimics as a student helped me develop transferable skills such as the ability to work with large datasets, problem-solving skills, and attention to detail. These skills have been invaluable in my career as a biomedical engineer and prepared me for the challenges of the field. Additionally, my experience with Mimics was invaluable in my transition from academia to industry, where my current position involves developing personalized healthcare solutions. The ability to create patient-specific 3D models using Mimics has given me a unique perspective on the challenges and opportunities of personalized medicine. I believe that this experience will be particularly valuable as the industry continues to evolve towards a more patient-centered approach.

In your opinion, what is the benefit of collaborations between researchers, surgeons, and industry partners?

Mr. Branni: Collaboration between researchers, surgeons, and industry partners is crucial in driving innovation and improving patient outcomes. By bringing together individuals with diverse expertise, knowledge, and perspectives, we can tackle complex healthcare challenges and develop more effective, efficient, and personalized solutions for the patient.

Researchers bring expertise in basic science and engineering, while surgeons bring a deep understanding of clinical practice and patients' needs. Industry partners bring valuable knowledge of product development, regulatory requirements, and commercialization. By pooling these resources, we can create new solutions that address unmet clinical needs and ultimately improve patient outcomes.

As an example from my own experience, I worked on a project where engineers, surgeons, and industry partners collaborated to maximize the use of preoperative planning software to improve clinical outcomes in shoulder surgery. By combining our expertise and knowledge, we were able to suggest the best use of these tools for improving patient outcomes, which led to successful innovation. This project demonstrated the power of collaboration in orthopaedic research and development and the potential to transform patient care.

What is your advice for researchers that would like to focus on personalized care in their careers?

Mr. Branni: First of all, when focusing on personalized care, keeping the patient at the center of your research is essential. Researchers should strive to understand patients' individual needs and work to develop solutions tailored to their specific conditions.

Secondly, collaborate with other disciplines, including clinicians, engineers, and data scientists. These opportunities will help you develop more comprehensive and effective solutions.

Last but not least, embrace emerging technologies; artificial intelligence, 3D printing, wearable devices, and others are changing how we approach personalized care. Researchers should be open to using new technologies to develop innovative solutions that improve patient outcomes.

And finally, what's next for the Centre?

Professor Pivonka: We plan to become one of the biggest shoulder research centers in the world. We want to be on the cutting edge of personalized and accurate patient care — using the latest technologies and techniques and providing the best training so our graduates can significantly impact the biomedical industry.

There are so many success stories from our students and graduates as they enter the workforce, and we want to continue highlighting this work by hosting industry events and celebrating exciting achievements, such as Dr. Lavaill's research on the effects of marker misplacement on shoulder kinematics and kinetics, which was the cover story of Life in June 2022. Having the students here to get that hand-in-hand training with clinical partners is essential and really a testament to this type of training setup.

L-103357-01

Share on:

Biography

Professor Peter Pivonka

Biography

Dr. Maxence Lavaill

Biography

Mr. Marco Branni

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.