INTERVIEW

How Is Materialise Becoming Greener? Through ISO 14001

Reducing the impact Materialise has on the environment is a complex task — it ranges from thinking about the plastics used in 3D-printed parts to the commute of its employees to what happens in case of an emergency. Materialise’s Director of Quality Management, Risk, and Compliance, Ward Callens, heads a team that uses ISO 14001 to reduce Materialise’s footprint. In the interview below, he describes the ins and outs of what this certification actually means and the important role that sustainability plays at Materialise.

What exactly is ISO 14001?

ISO 14001 is an environmental management system. When you pass the external audit, you get a certification to state that your system is in compliance with a generally accepted international standard. That’s true for all ISO certifications. We already have certifications for quality management systems — in medical, in software, in general manufacturing, and specifically for aerospace, etc. And a few years ago, we added this one for the environment. And what it means is not necessarily that we are a green company or that we make green products, but rather that we have a system in place to assess, control, and lower the impact we have on the environment in general.

How do you get ISO 14001 certification?

You first have to start with a full analysis to know every possible environmental impact the company has. So that can be in terms of garbage and pollution, or in terms of leaks or what can be put into the water, air, or soil. But it also includes other things, like noise, odor, and so forth.

The certification is all about plan, do, check, act. It’s about setting up a plan of what you are going to do, identifying your impact, monitoring it, and systematically trying to lower them. Also, it’s about having plans in place for emergencies or accidents. For example, what are we going to do if there is a fire? A fire typically has negative environmental impacts, apart from everything else, so there are things we need to close off to prevent explosions or pollution. And it’s not enough if they’re simply there; they need to be used in practice.

Could you give an example of how you have lowered Materialise’s environmental impact already?

A good example is that we have hundreds of people commuting on a daily basis to Materialise. That has a negative impact on the environment — you have the CO2 emissions if they come by car, you have traffic, you have insecurity for pedestrians and cyclists, etc., so these are all elements to take into account and then you state, ‘Ok, we are going to set a target to reduce that.’

So how can we do that? Well, by stimulating the use of bicycles. By giving people more money to compensate them for train passes. We also introduced a bike leasing plan for all Belgian employees. They can lease a bike — even an electric bike — like you would a company car. We also have some charging stations for electric cars that employees can use. And we are trying to find ways to promote and stimulate carpooling.

As a result of all of this, by the end of 2018, more than 40% of Materialise Belgium employees at least occasionally rode their bikes to work. And I think that’s a fantastic result. It doesn’t mean on a daily basis, that is lower, but it is something that is really showing results.

Why is it so important for companies to have this system in place?

The main advantage of having this certification is that it forces you to think about environmental management systematically. Once we know what the main issues are, we can then look at all the impacts and decide which ones are most significant or at a level that we just cannot accept.

You could probably also come up with ideas to be greener if you didn’t have the ISO 14001-certified system. But the system forces you to do a number of important things. At least once a year management needs to come together and think about objectives that we can state with respect to the environment. And we need to think about actions, monitor the progress of those actions, and take action if things are not progressing quickly enough. Those are things you wouldn’t necessarily have the discipline to do if they weren’t part of the system.

And why is it so important for Materialise specifically to have ISO 14001 certification?

Materialise is all about sustainability. Even in our mission statement, we say that we are innovating product management to lead to a better and healthier world. So inherently, in everything we do, we want to have less impact on the environment and be more sustainable for the very long term.

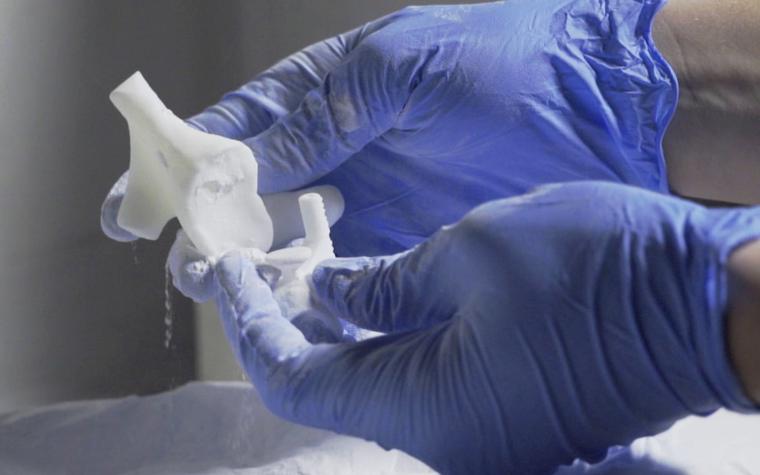

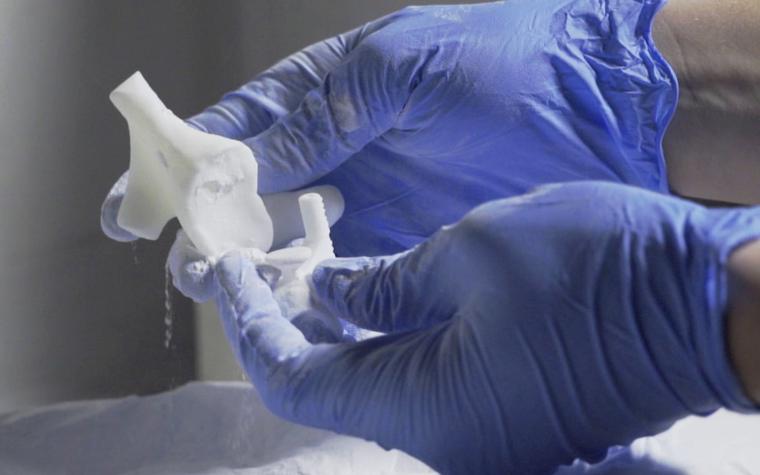

We’re also producing a lot of plastics, but we do it in the best possible way. 3D printing is a very good technique to make products because you use a lot less material. And by consuming less plastic as a raw material, you can then save on weight, which, in aerospace applications, for instance, can lead to a reduction in fuel use. You can also produce only the parts that you need at the time that you need them. So that means that you save on storage space and unused parts that have to be scrapped afterward because it turns out you didn’t need them in the first place. You can print locally — put your machine at the place where it will be used, which is what we do on the medical side. We do not print any guides in Belgium that are destined for the US market — we print them directly in the US, so we save on transportation costs and plane weight.

So if we know that sustainability is inherently linked to the technologies that we have, then as a company we want to show that it is not just 3D printing that is environmentally friendly or less impactful but that in our entire operations we want to limit the impacts that we have. That is why a system like ISO 14001 is something we absolutely have to have in place.

What other things are you thinking about under this framework?

We also use a lot of hot water to dye parts — for example, to color eyewear frames that we print. This process does not heavily pollute the water, but still, we don’t want that water to spill. So we have backup containers underneath the water dye collecting containers. This means that if there is a leak, it is still possible to collect the water. The next step will be to check our options on how to heat that water in a more efficient way.

When we built our newest building in Leuven we already had ISO 14001 in place and it helped to ensure that we asked a lot of questions during that project, like how the lighting would be done and how the air conditioning would be organized. And how we could ensure that there would be tanks to collect rainwater and use that rainwater to flush the toilets. So these are all things that were already in our minds before construction began.

The rooftops of all of our buildings at HQ are covered with solar panels. We’ve also been looking into the possibility of constructing a windmill which would cover quite a substantial amount of the energy that we need. Unfortunately, that is not going to be possible because we are really in a bad location for this — we’re too close to the railroad line, too close to the airport, so it would interfere with all kinds of radar systems. But we’re hoping to find another way that we can really make our energy consumption even greener.

All of these things have really been thought about. Not everything has been realized yet, but again the ISO system makes it possible to really implement and monitor all these kinds of actions.

What types of things would you like to do in the future to reduce Materialise’s environmental impact?

There are lots of things we’d like to do in the future. We’re continuously searching for further improvements, further reductions. There are many things we can still do on the product side, such as explaining to customers what they should do when the product that we printed for them reaches its end of life. And maybe even further than that. Can we help in the recycling process? Can we help customers think about end-of-life concepts, such as product lifecycle analysis? It can be as easy as just explaining, ‘Ok, this product contains this type of plastic. You can recycle it like this.’ Or, ‘This product is made out of this material, and there is no good recycling option, so this is going to be general garbage.’

For heavy users, we could recommend plastic collection so they reach the right kind of recycling strategy. We could help customers to consider producing less but in more meaningful ways. So again, you see how it fits with the strategy of Materialise as a company, how it fits with our vision. We just have to keep moving forward, keep reporting, learning, and becoming better. Even the smallest things can make a significant difference and help reduce our environmental impact.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.