EXPERT INSIGHT

Qualifying Aerospace Parts: The True Roadblock Slowing AM’s Rise

Additive manufacturing’s value has been proven in the aerospace industry time and time again. But the industry has yet to use the technology to its full potential. In this article, Erik de Zeeuw, Market Manager for Aerospace at Materialise, explores why this is the case.

Although aerospace frequently turns to additive manufacturing (AM) for prototyping — 78% of companies, in fact — only 18% of them utilize it for flight-ready end-part manufacturing.

It’s not a lack of suitability that’s limiting these numbers. 3D printing is a valuable addition to aerospace manufacturing — from quick lead times for part replacement to cost reductions and design optimization. So, what is the factor holding the industry back?

The answer: part qualification. This gap is due to a lack of standardized performance data for 3D-printed components. It’s certainly an issue worth finding a solution for, but AM’s relative infancy compared to other forms of manufacturing doesn’t make it a simple task.

Why should we find a solution?

Before diving into the options, let’s quickly review the advantages offered by AM in the aerospace industry. There’s one fast-growing opportunity in the aerospace sector to go over in particular: low/no criticality part production.

There are many examples of this where AM shines: interior cabin panels, functional brackets, ventilation system components, and more. At Materialise, we print approximately 700 part series in this category per year. And 26,000 of these individual parts are printed for the Airbus A350 ecosystem alone.

AM offers numerous valuable advantages for these types of parts: quick lead times; no tooling costs; spare parts taken from virtual shelves that eliminate excess stock storage costs; reduced risk with tight overhaul, maintenance, refurb, and manufacturing schedules; and no minimum order quantities. You can understand the impact these have on supply chains and sustainability goals.

But it doesn’t stop there. This list covers printing like-for-like parts, but by designing parts with AM in mind from the get-go, the benefits multiply. For example, lightweight parts, quick and easy iterative part adjustments to optimize part performance, and part consolidation for uncomplicated assembly make a major difference. A recent study carried out by PWC showed that reducing the weight of an aluminum bracket by 40 – 50% — through component redesign and optimization with AM — enabled up to $700 million in fuel savings over a five-year period.

The need for standardized part qualification

Although many organizations are already reaping these benefits, it’s fair to say that there’s much more potential for AM when manufacturing low criticality parts. A key factor for why there is so much room to grow here is because part qualification for low criticality parts is less stringent. In 2020, the European Union Aviation Safety Agency (EASA) released a memorandum recognizing the distinction between low and high criticality parts. They also encouraged design organizations (DOAs) and production organizations (POAs) to collaborate on part qualification for low criticality parts.

This suggestion makes a lot of sense. Collaboration is absolutely crucial to ensure that part qualification is systematic. However, that doesn’t mean it’s a simple task. High requirements for part performance make it a bit more challenging.

But AM is up to the task. It has the capability to build reliable, high-performing parts, but the challenge lies in demonstrating that the parts meet the expected performance, are consistent in quality, and reach the relevant safety criteria.

The major roadblock is that DOAs need data from POAs to assess and qualify parts. And there isn’t a clear consensus from DOAs on the required data. It wouldn’t be surprising to see three different DOAs request entirely different data sets to validate just one part. Consistency is a difficult target to reach without a standard approach for these specifications. The industry is constantly ‘reinventing the wheel,’ hindering progress.

What are the next steps?

If we’re to overcome this challenge, the long-term solution is introducing an ISO standard for 3D-printed parts to specify data and performance parameters for a part qualification process that meets universal needs. In the meantime, there are actions that POAs and DOAs can already take to help the industry meet this goal.

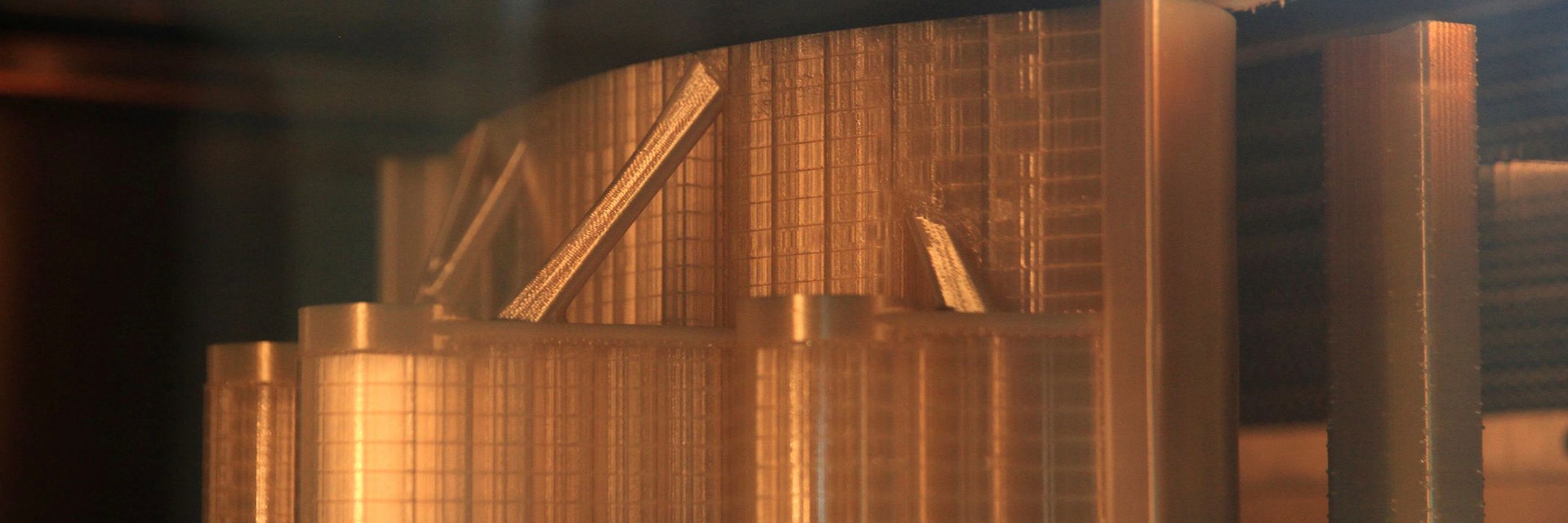

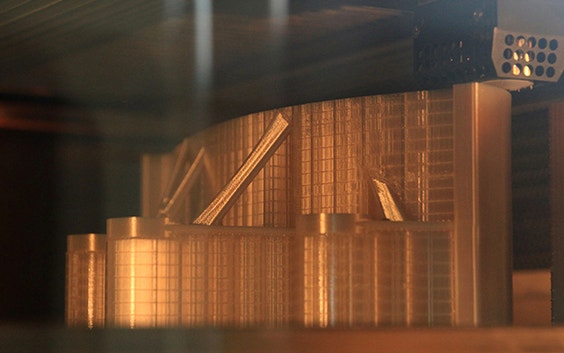

POAs should focus on demonstrating reliability and repeatability while providing DOAs with as much data as possible. Here at Materialise, we’ve been an EASA 21.G-certified production organization since 2015, so we have a wealth of part performance data to leverage. With more than 3,000 data points from approximately 200 builds, this ‘data lake’ illustrates the impact of design on mechanical properties, part density, tensile strength, and more. Factoring in process control documentation, this information demonstrates results over time. Documentation is critical for consistency, so it’s our aim to constantly update this ‘data lake’ to use as a resource for optimal decision-making.

And for DOAs, they’ll need to collaborate with POAs and other DOAs in order to ensure that this approach to data is the norm. The sooner we take these steps, the sooner a standardized part qualification process will be attainable.

What does the future hold for aerospace and 3D printing?

I believe that standardized data is indeed the most significant obstacle we’re currently facing in the use of 3D-printed aerospace parts, but this evolution will be two-sided.

For example, as 3D printing grows as a manufacturing option for critical components, additional fine-tuning of the processes and materials will be necessary. And along with this comes the importance of data collection and analyses of part performance.

The key factor is collaboration. We’re well on our way — with initiatives in the industry already in place — but we need to ensure that it remains a priority. And soon enough, AM as a mainstream production method for end-use parts will be our reality in the aerospace industry.

Share on:

Meet the author

Erik de Zeeuw, Market Manager, Materialise

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.