EXPERT INSIGHT

35 Years of Making a Difference: Expanding Access for a Healthier Tomorrow

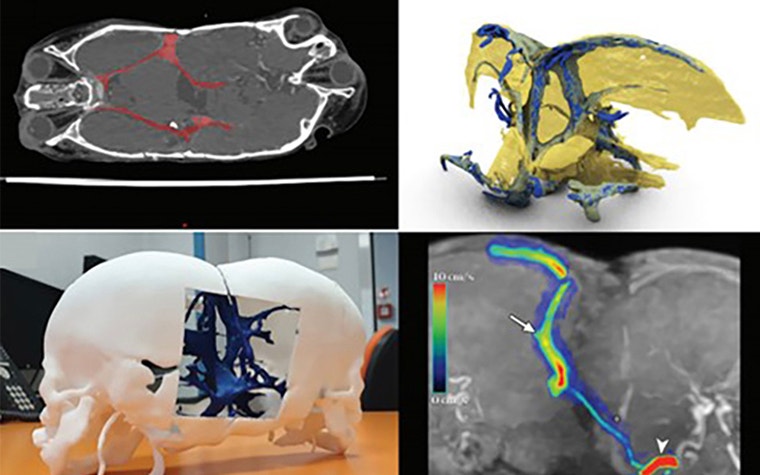

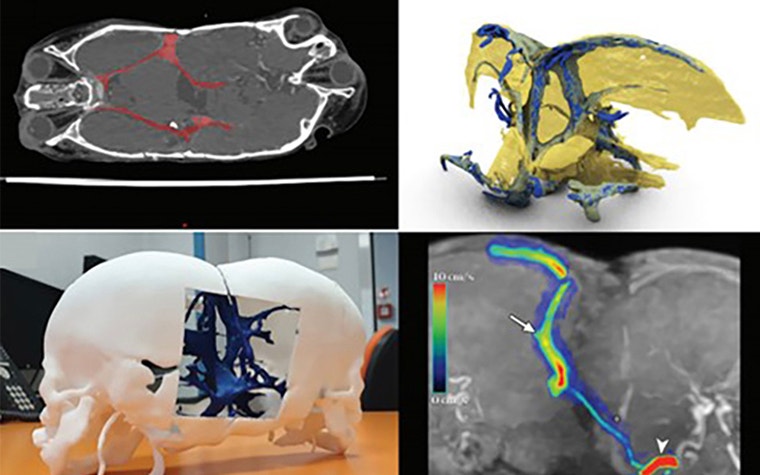

Healthcare advancement isn't about quick wins — it's about sustained progress. Over the past 35 years, we've innovated and collaborated to advance our goal of making personalized treatment available to all. One size does not fit all. Each patient deserves care tailored to their unique needs, and 3D technology is instrumental in making that possible — from 3D-printed anatomical models to virtual surgical planning. To date, hundreds of thousands of patients' lives have been touched by our solutions, and this is only the beginning.

A belief that inspired change

"When you look at the impact that this has on the life of the child, there is no doubt that the value added to that child, let alone the healthcare system, is substantial." It's stories like Dr. David Hoganson's that Fried Vancraen dreamt of when he started Materialise 35 years ago.

These days, the Department of Cardiac Surgery at Boston Children's Hospital has fully embraced 3D technology in its routine. It's used in about 500 cases per year, which accounts for half of their workload — a number that continues to grow. 3D planning and modeling provide insights that were unobtainable with traditional 2D imaging. Dr. Hoganson uses virtual planning software to plan and perform in-depth analysis of each treatment option, ultimately determining the right choice in a risk-free environment.

"The peace of mind cannot be underestimated," he says. "You’re doing your best, but without this workflow, you don’t know for sure what should be done. Fundamentally, that’s unsettling."

This is a powerful representation of how Fried's vision has impacted the industry. And there are countless more cases like it.

From world firsts to standard procedure

Materialise's early history in healthcare was driven by a mission to improve accuracy. A 3D-printed anatomical model was only as good as the imaging it was based on, and distortions from patient movements during CT scans were prevalent. Determined to bring innovation to the field, our team developed spiral CT scanning technology — a breakthrough that laid the groundwork for everything that followed.

Since then, Materialise's impact has grown exponentially. From academia to medical device companies, cranio-maxillofacial to respiratory — our technology has made a difference in nearly every corner of healthcare.

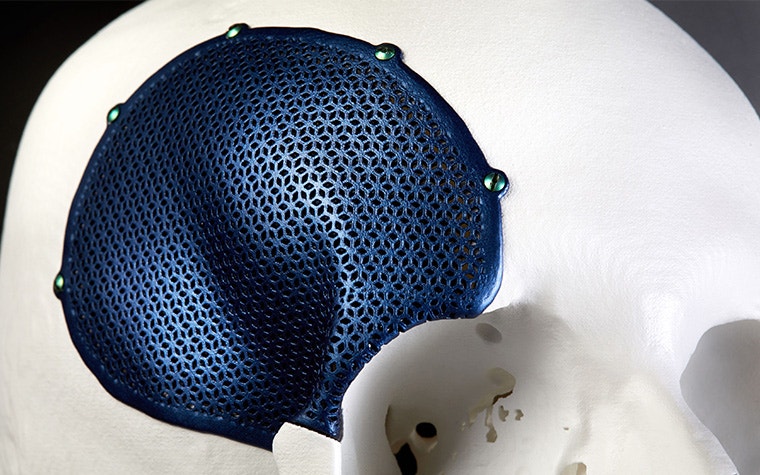

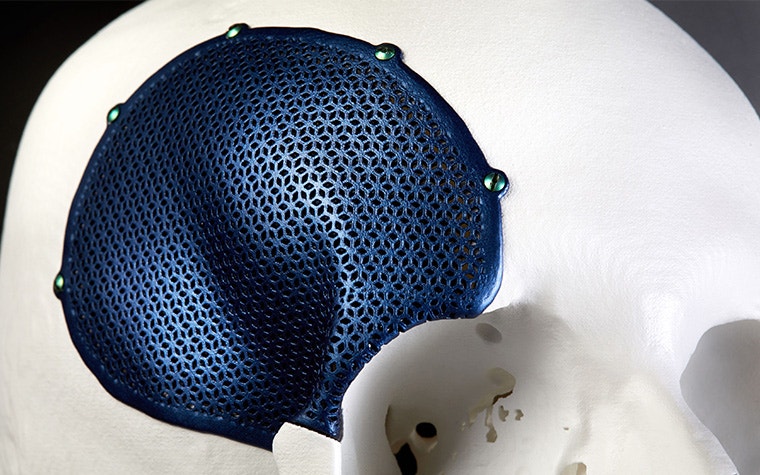

One notable milestone was reached in 2006, with the launch of the first titanium 3D-printed skull implants. These patient-specific implants feature intricate porous structures that mimic natural bone, demonstrating the power of 3D printing in healthcare. Based on patient scans, surgeons could receive the implant relatively quickly — today, in as few as seven business days for certain orbital procedures. From there, the surgeons are ready to enter the procedure with a clear plan, restore symmetry, and attain more predictable outcomes.

The 3D printing innovations for solutions designed to work seamlessly with human anatomy didn't stop there. One important case sparked a groundbreaking, life-saving treatment in early 2012. Each day, this infant patient stopped breathing. A collapsed bronchus due to severe tracheobronchomalacia was blocking the crucial flow of air to his lungs. The solution? 3D printing a tracheobronchial splint with polycaprolactone, a biodegradable material that is gradually absorbed into the body over the years.

In 2012, this innovation addressed an unmet need and saved a patient's life, paving the way for a major accomplishment this year: entering a pivotal clinical trial for the technology. This eight-year study will enroll at least 35 infants and children at the University of Michigan Health C.S. Mott Children’s Hospital and other study sites. Materialise Mimics has played a crucial role in the device development, supporting image-based design for more than 40 pediatric patients since the first case.

A project of this magnitude doesn't come without hurdles, of course. In order to secure the FDA’s Investigational Device Exemption, a lot of effort went into validating mechanical properties and demonstrating consistent manufacturing quality. By closely collaborating with the FDA, we shaped a regulatory pathway unique to this technology.

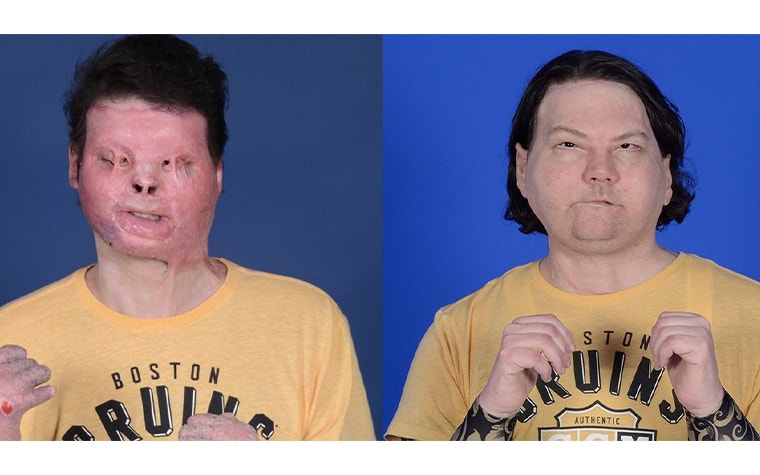

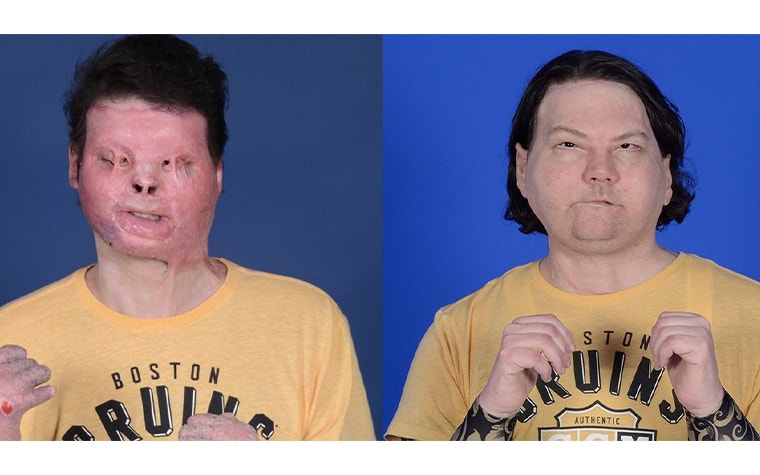

Our contributions don't stop there. We've supported more world firsts, including face transplants, eye transplants, and the separation of conjoined twins with a total posterior craniopagus.

These are all incredible accomplishments, but our mission goes beyond innovation — it's about accessibility. The numbers demonstrate the growth, with 6 million patient scans analyzed with our software, 500,000+ patient-specific models, guides, and implants created, and recently, an astonishing 60,000 patients helped annually. And there will be many, many more to come.

What do the next 35 years hold?

Looking ahead, we see endless potential in personalized care. Advances in digital tools are reshaping treatment planning and delivery, with AI and machine learning accelerating our current manual processes. In the not-so-distant future, we believe that what now takes 10 – 12 hours will take just one.

One specific AI advancement we've already implemented to support surgeons is within our planning tool for shoulder operations. It advises a recommended approach based on successful surgeries from other specialists, providing surgeons with a promising head start for each procedure. In Mimics, users are also getting more out of their workflows with AI-enabled segmentation. AI handles the previously manual and time-consuming task so teams can direct their energy towards higher-value work instead.

Augmented reality (AR) is also making waves, allowing surgeons to virtually rehearse surgeries before entering the operating room. Eventually, we envision AR replacing physical surgical guides, offering next-level visualization and precision.

3D printing and planning at the point of care are rapidly becoming integral to everyday clinical practice. What started as a technology embraced by early adopters is now transitioning into broader implementation on a global scale. This shift is fueled by significant advancements in automation, AI integration, and operational efficiency.

As reimbursement initiatives gain traction, the value of 3D printing is becoming increasingly clear — not just in improving individual patient outcomes but in driving cost-effective solutions for healthcare systems. With a steadfast commitment to innovation, we're building a future where 3D planning and printing are cemented as the standard.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.