EXPERT INSIGHT

6 Questions to Ask Before Starting with 3D Printing in Your Hospital Part 3

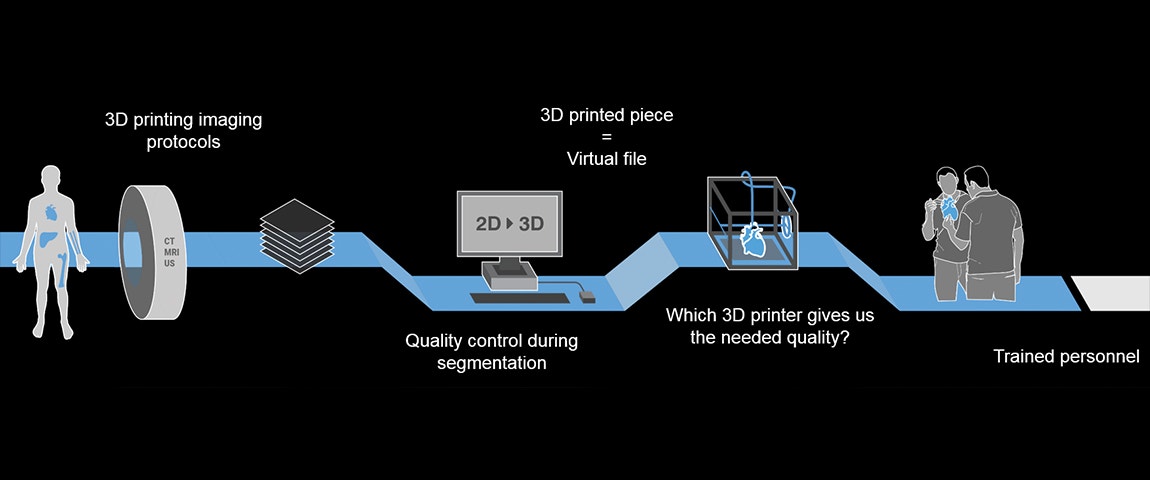

As we saw in parts one and two of this series, 3D printing has enormous potential for hospitals, but it requires software tools and know-how. In this final chapter, we discuss the hardware options as well as the need for an efficient communications process.

How can you streamline communication within your hospital?

Communication

The key to good communication is fostering close collaboration between staff members. The scope and use of the model should be defined with the surgeon or interventionist before starting the process, and should be verified additionally near the end. This can be facilitated through web meetings or face-to-face discussion. It can also help to have a software solution capable of exporting a file format which can be interrogated by the surgeon. It is doubtful whether your surgeon will be able to open an STL file, and exports such as 3D PDFs can be an excellent tool for this purpose.

Ordering

How does a surgeon indicate when they would like a model to support a procedure? Do they send an email or walk to the lab to discuss in person? When does it make sense to implement a more sophisticated ordering system? There is no clear answer for this. However, this shouldn’t hinder your ability to get started. Start simple and develop close working relationships with your surgeons before building a more robust system into the clinical workflow.

To insource, or to outsource?

Insourcing or outsourcing? That is the question. Outsourcing allows you to minimize your upfront investment, but it is typically associated with longer lead times. Outsourcing can also be advantageous in the rapidly evolving market of 3D printers. What you buy today could soon be obsolete with better and lower-cost technology being brought to market. From a purely economic standpoint, outsourcing would be the best strategy.

However, if you do decide to invest in a printer, where should you start? 3D printers come in a variety of different technologies that all have their advantages. FDM, PolyJet, laser sintering, stereolithography, and ColorJet Printing all have unique advantages for certain applications. Resolution, speed, materials, color, and, of course, cost are all key factors you should consider. It is always good to consult experts in the industry to understand which technology makes the most sense given your use case and budget.

In addition to understanding what the best 3D printer is for your program, you’ll also need to take into account the space required to house it. Certain printing technologies take up a very small area, while others may require dedicated facilities. Some machines require additional equipment to clean the models after printing or will have greater maintenance associated. It is necessary to fully understand all of these considerations before making your choice.

Is it worth it to train personnel?

You will need specific skill sets to run an effective 3D printing service. Knowledge in imaging and anatomy/pathology is required for accurate segmentation. A level of engineering skill is also needed to prepare your 3D models in the best way for printing. Additional resources may be needed to clean models and maintain machines. The scale of your operation will determine the resources. Start small and lay out a plan for growth.

Starting at a small scale will help build momentum with clinicians and administrators to support the activity. Make sure to learn from experts in the field. Master the process from image acquisition through 3D printing. This will ensure that you avoid common pitfalls and are operating in the most efficient way possible.

Other considerations

Although 3D printing as a core service in hospitals is still in its infancy, many innovative institutions have been blazing a path. Consult the experts both in the industry and among your peers who have developed similar programs. This might mean visiting other established medical 3D printing facilities or working collaboratively on a few cases as a service. Establishing a new technology such as 3D printing can seem like an overwhelming endeavor, but by taking into account the many considerations and requirements, you will be able to develop a starting plan and grow a successful service for your institution.

If you haven't had the chance to do so yet, check out the first and second part of this blog series. Or watch the webinar recording on implementing 3D printing in your hospital to learn more.

This blog is based on an article first published on auntminnie.com

L-102880-01

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.