INTERVIEW

3DP&Me: “Unique Eyewear Was The Goal, 3DP The Enabler”

An interview with eyewear designer Fabián Hofmann, co-founder of NEON BERLIN

Welcome Fabián. Could you tell us about when you first encountered 3D Printing (3DP)?

I actually first explored 3D technologies in relation to ceramic tablewear – that was about 20 years ago at my design agency in Berlin. 3DP was in its infancy then and while everyone was curious and excited about what could be done, the capabilities available at the time didn’t really match expectation or imagination which for me was incredibly frustrating. The processes and materials were still immature, and also extremely expensive. I ended up losing touch with 3DP at that point but it was always a technology I intended to revisit.

That happened about 7 years ago when one of my eyewear clients asked me to look into options. Suddenly I had a fantastic opportunity to examine how techniques and technologies had evolved. To find out if the frustrations I had faced many years ago were now a thing of the past, particularly in terms of design optimization. For me, there is no point in using a particular production method unless it can become part of the design DNA. It was around this time that I first began speaking with Materialise who already had a strong reputation in this field.

As it turns out, the project for that particular client didn’t end up progressing. But when it came to 3DP, I was once again hooked on the incredible opportunities that I could see unfolding.

Could you give us a little background on NEON BERLIN? Was 3DP involved right from the start?

3DP completely fascinates me so I always saw it as having a big influence on my future. I’d worked with a lot of global eyewear brands of course, but in going out on our own with Neon Berlin, I knew we would have the chance to do something really new and creative with 3DP - to push the limits of technology.

And I wanted to drive that. Be active, not passive in the process. My business partner Coerte Voorhees and I wanted to be part of the creation flow, so we developed a very interesting relationship with Materialise; a true partnership with both sides sharing expertise and original ideas. Working together this way, you can really innovate, do things that you couldn’t do if you were a client that just says, ‘hey, I’ve heard about 3D printing and I want to do some stuff that would be cool’. That’s not what makes this whole process successful. You need to understand how the technology works and have some idea of how to produce the look and feel you’re aiming for. It goes back to my earlier point about DNA.

“The more good designers show different ways of using 3DP, the more it becomes the norm. I’ll be happy when everybody is doing the right thing with 3DP.”

For you, where does 3DP production score most highly for independent eyewear designers?

3DP’s design freedom is a really big attraction. You can create impressive shapes that are impossible with conventional processes like injection molding or milled materials like acetate which can shrink and buckle. It’s the same with titanium – you could never take a block of titanium and mill a component from it that is both thick and then immediately super thin like you can with 3DP.

People think that design is about making things pretty but what I always say is that design is about making things work. The 3DP design process is not just a visual thing, it’s a whole way of thinking and engineering is a big part of that. If you fully understand how weight and torque are distributed in such a delicate product, you can use complex surfaces and curves to make super-lightweight components.

3DP is also super sustainable. You print what you need, wasting very little. In addition to the positive environmental implications of that, it’s a process that offers innate flexibility in terms of design iteration; you can be incredibly responsive which allows you to be much more ‘in the moment’ which for a designer is incredibly powerful.

Of course, 3DP is also famous for letting you customize each set of 3D-printed glasses to the customer but I’m not completely convinced that we should be going too far down the road of scanning faces and so on. I think some might be surprised to hear me say that. Customization is interesting but not often necessary. For example, our Bestiary range has a selection of temples so opticians can change between different temple lengths and colors immediately, giving them easy in-house customization without the need to go “all out”. It’s about balance.

How hard was it to take Bestiary from initial design to additive production?

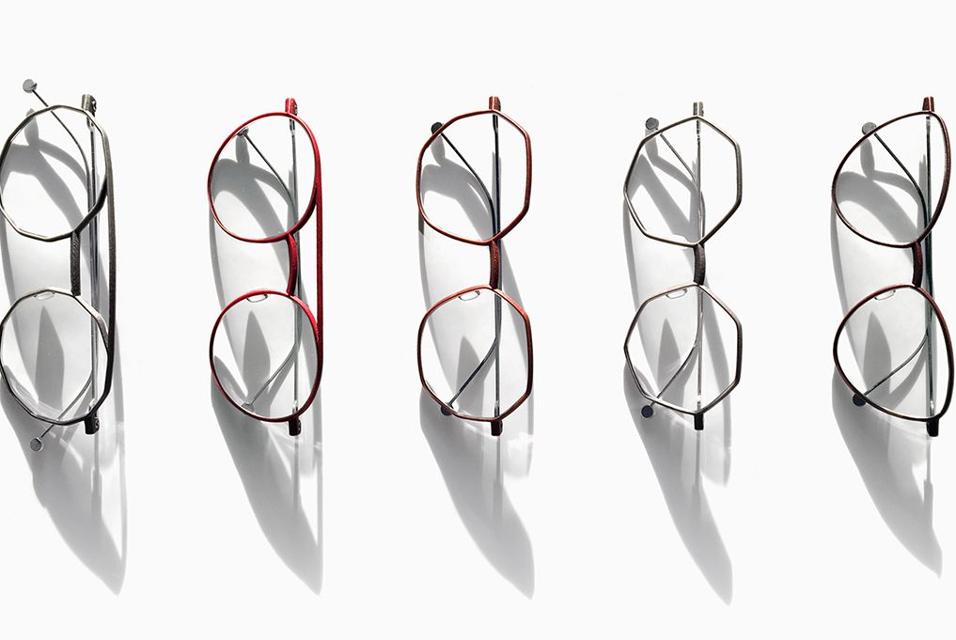

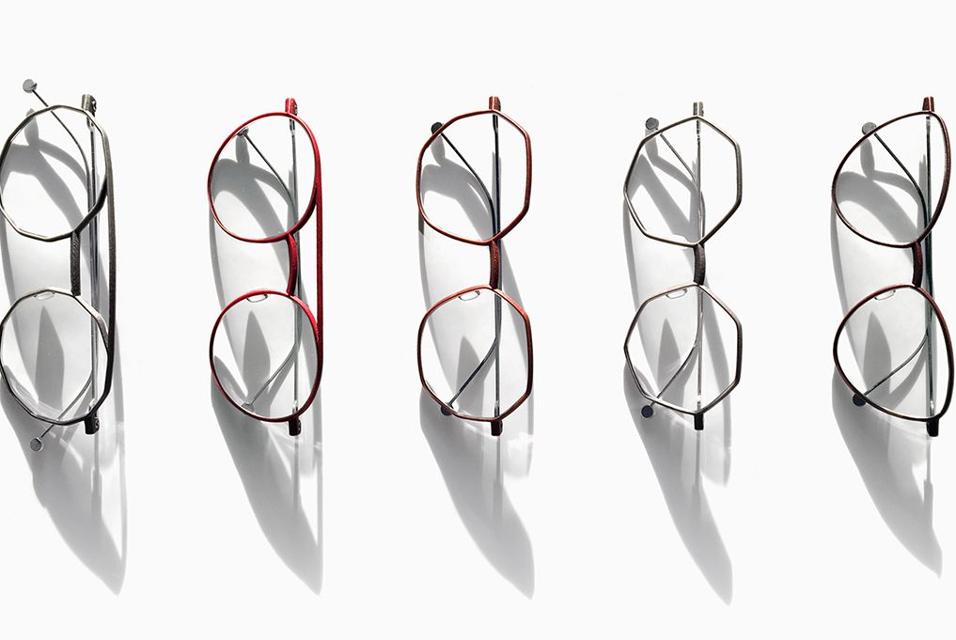

Developing the Bestiary collection was a two-year journey of experimentation and discovery unique to the process. It was never about just recreating 2D subtractive designs, we really wanted to exploit 3DP’s potential and find solutions that make the most of the materials available in ways that simply hadn’t been done before. Unique eyewear was the goal, 3DP the enabler.

Were elements of that process difficult? Sure. For example, when we were designing a specific titanium part and marrying that with polyamide for Bestiary, we had different materials, different tolerances, and different production processes. You might think that’s simple to accommodate but this precision with tiny working parts is something new for 3D. Making these two parts happy to live together and suitable for series production took months of engineering time. The same kind of effort went into the temple arm which cold bends to give an exact fit.

And of course, we wanted to push the limits, and become super-thin, almost like a wire frame made out of metal. So we started to think not in terms of creating, extruding, and sculpting a shape from a 2D pattern like it is quite common in 3DP, but to think of the glasses as if they were bent in 3D space, made out of wire instead of a virtual flat slab of material. Quite similar to designing classic acetate frames in comparison to metal eye-rim glasses. That was the game changer, it enabled us to create a completely different work environment for us. It completely changed the workflow right down to the actual production processes.

In the beginning, I’m convinced everyone at Materialise must have been sighing and saying, ‘can’t you do something simple?’ But they put 100% creative effort into all the different ideas, just like we did, which meant we could reach new endpoints. Both sides learned so much from this journey.

What did you enjoy most about Bestiary and applying 3DP to eyewear in general?

New processes have to be invented all the time, and that is what makes working with this technology so worthwhile; and exciting. I’ve done so many acetate and metal designs, I find it almost too easy. This is precisely where I want to be in my life and I have a lot of passion for it.

With Bestiary, we don’t just design a pair of glasses, print them, and that’s it. We developed a new surface treatment with Materialise, which was then hand polished to give a leathery yet glossy, extremely luxurious finish with incredible depth. Those complex, folded, facetted origami style surfaces help bring a look from the late 50s and 60s right into the here and now, just thinner. There is something so satisfying with that marriage of new and old.

Coloring is another interesting and, for me, enjoyable 3DP challenge. It’s one of the most important eyewear features – opticians are always asking for new colors. Remember with 3DP it’s not like simply dipping white plastic into a color of choice; color is created. There are physical and chemical processes involved with inhibitors and activators. You might start with green but the end product might be brown. Color creation isn’t just about decoration in this respect, at least it shouldn’t be. It is part of the design itself – part of the physical process.

Why is it so important to have products that are at the leading edge?

It’s necessary to demonstrate what 3DP can deliver, to explore. Even the craziest designs are a showcase to attract people. Opticians will come and look, then ask if you have more mainstream glasses as well. That’s beneficial for the whole industry. On the flip side, if 3DP eyewear goes too cheap, too fast, that could hurt and even temporarily halt progress. Low-end products with garish colors and bad surface treatments, uneducated opticians who don’t explain to their customers why 3DP eyewear is different – these are growing problems.

The more good designers show different ways of using 3DP, the more it becomes the norm. I’ll be happy when everybody is doing the right thing with 3DP.

Share on:

Biography

Fabián Hofmann

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.