CASE STUDY

Unlimited Design Freedom and Short Lead Times for Titan’s Jewelry Business

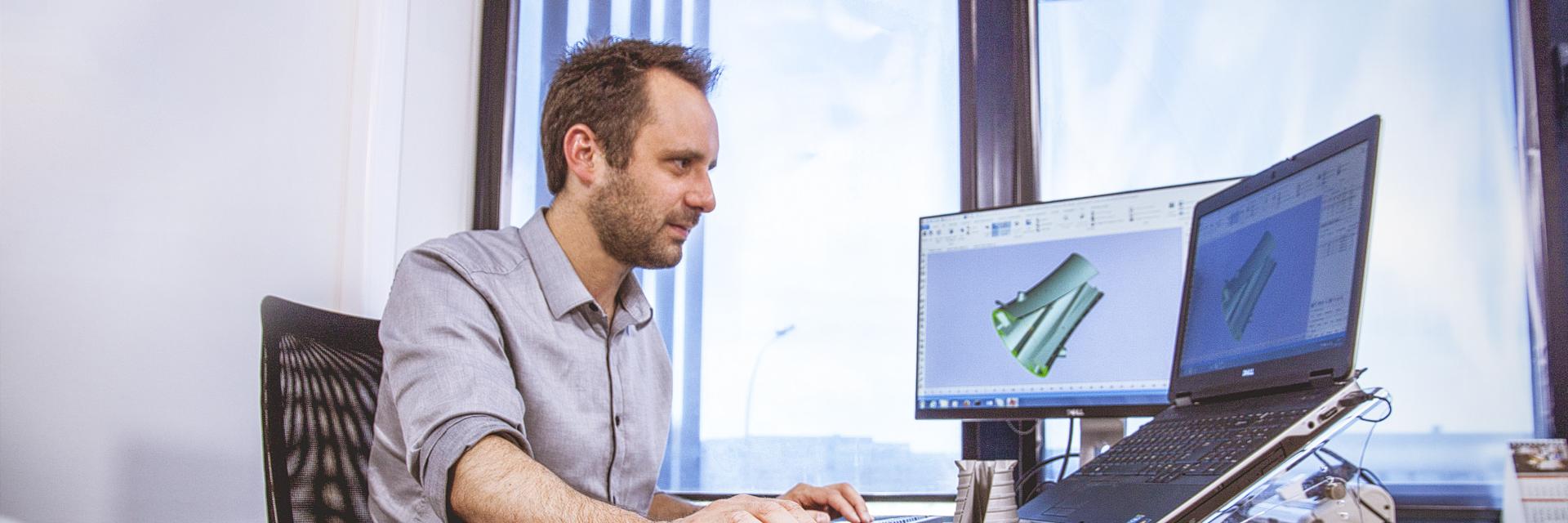

Jewelry lovers, especially in India, are familiar with the names Tanishq, Gold plus and Zoya. Three exclusive brands created by Titan Company Ltd, a company with decades of experience in manufacturing quartz watches and exquisite jewelry. To keep up with the demand for innovative and intricate jewelry products, Titan Company relies on 3D printing technology. 3D printing gives them unlimited freedom of design, and it also shortens their lead times significantly. With Materialise Magics, they are able to take full control of the data preparation process.

Speeding up the product development process

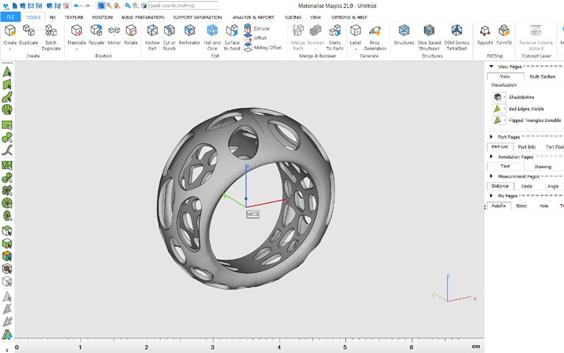

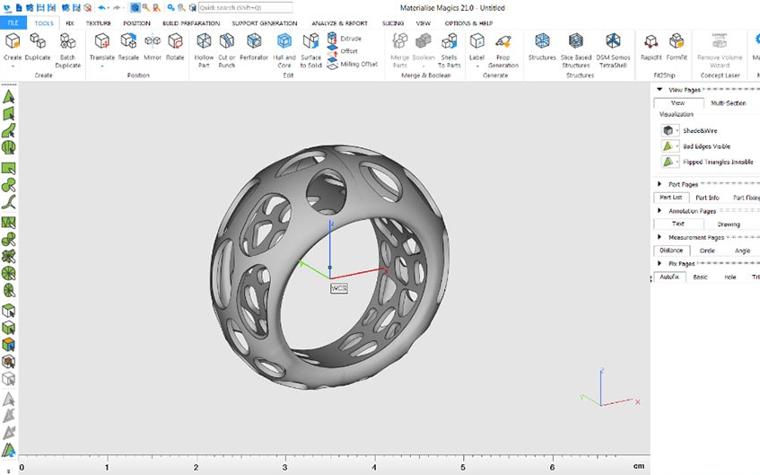

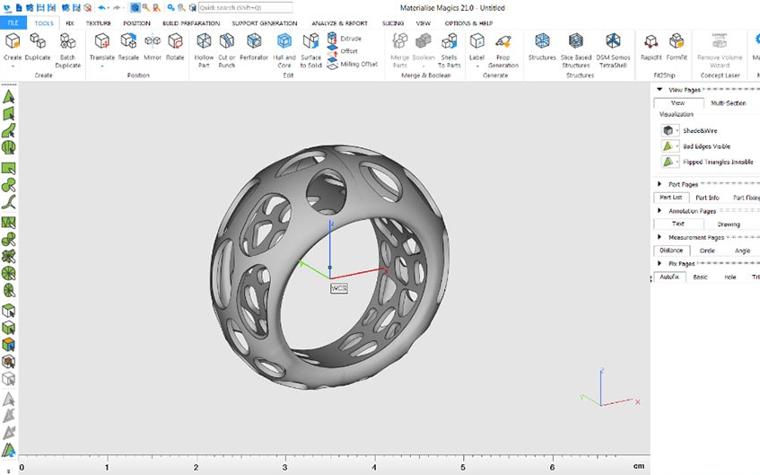

Before using 3D printing technology, Titan Company was more limited in the development of new products. They would cast their precious metals in a traditional way. Now they put their design in a CAD file, convert it to STL and make it ready for 3D printing with Materialise Magics software. A few hours later, the 3D-printed resin part is ready. This part is used in the casting process to replace the model that was crafted by hand. The next day, the stunning piece of jewelry can be delivered to the customer.

Materialise Magics plays a major role in Titan Company’s day-to-day 3D printing business. They use it to convert SLC files to STL, fix STL files, reduce the file size and smoothen the mesh.

“Materialise Magics makes STL validation and repair much easier. It also gives us more confidence to 3D print parts without any defects or deviation, leading to innovative, high-quality products for our customers.”

— Mr. Karthikeyan, Manager of New Product Development at Titan Company Ltd, Jewelry Division.

What did 3D printing technology change?

Design freedom and short lead times; these are in a nutshell the advantages of using 3D printing technology for the jewelry industry. Mr. Karthikeyan describes the advantages for his company in the following way:

- The turnaround time from design to product development is reduced drastically

- More clarity in meeting the objectives of the designer and development team at a very initial stage in the product development cycle

- We can modify the design with less effort and a shorter lead time

- We can reach an optimal level of dimensional accuracy

- Our design details can be more precise

- We can maintain a very accurate symmetry in the product

- Compared to the traditional process, the products can be sized and multiplied in quantity in a minimum of time

Share on:

This case study in a few words

Consumer goods

Art & Fashion

Print designs for the casting process

Materialise Magics

Speed up the product development cycle of jewelry production