CASE STUDY

Helping Heal Injured Poor around the World with SIGN

SIGN Fracture Care International is dedicated to treating victims of orthopaedic injury throughout the developing world and uses Materialise Mimics to develop and conduct computerized strength tests on implants.

"SIGN has been using Mimics to develop and conduct computerized strength tests on SIGN implants since 2002 when Materialise first donated the product to SIGN," said Lewis Zirkle, President and Founder of SIGN Fracture Care International. "Fried Vancraen, CEO of Materialise, partnered with SIGN to help injured victims in Iraq during the height of the conflict. Materialise continues to assist us with new designs and innovations of existing designs. We are very grateful for this technology."

Throughout the world, untreated leg fractures are leading to permanent disability and long-term hardships for those injured as well as their families — with the majority of accidents affecting the working poor. With more than 50% of the world’s population surviving on less than $2 per day, a disabled family member who cannot work can drag the entire family further into poverty for as many as three generations. In order to prevent this bleak outcome, SIGN Fracture Care International is dedicated to treating victims of orthopaedic injuries throughout the developing world. To do this, the organization collaborates with local surgeons to develop specialized training and implants, thereby supporting local efforts to provide effective orthopaedic surgery to the poor. With SIGN’s help, surgeons in the developing world are able to treat more patients and speed up the healing process, enabling patients to return to work and continue supporting their families. Materialise proudly supports SIGN in its efforts by donating software that enables the design of new implants and innovations in those that already exist.

Bringing treatment to the working poor

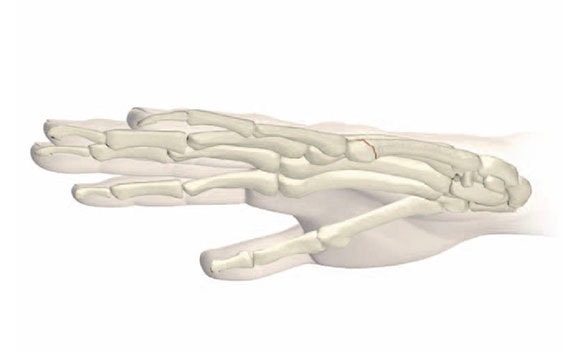

In order to bring fracture care to patients in developing countries, SIGN implants are designed specifically for the conditions faced by local surgeons. SIGN’s system resembles the standard solution used to treat fractures in developed countries (using intramedullary nails which are held in place with interlocking screws), but the SIGN system is designed for use in facilities that do not have C-arms or power equipment. With SIGN, surgeons are educated to use tactile sensation instead of C-arms, and this training is combined with depictions of what is happening inside the bone to help the surgeons better accomplish their job. For the design of their standard nails and screws and a better understanding of what is happening inside of the bone, SIGN uses the Mimics platform.

Implanting hope through innovative design

Using Mimics, SIGN segments bones of interest (e.g., the tibia, femur, and humerus) in order to better understand the process of fixing the implants from within the bone canal. For example, SIGN uses straight instead of curved nails, and in Mimics, they were able to determine that a 3-point fixation using their straight nails was superior to the curved nails currently on the market. Likewise, in order to further develop their own unique intramedullary nails with stable fins, which they have been using in the femur for many years, SIGN used Mimics to better understand the canal of the tibia. This gave SIGN an understanding of how to use the fin nail for the tibia, which is especially important as the fins take the place of the interlocking screws.

SIGN has also developed a pediatric femoral nail based on the fin-like nail, a solution that is already working very well. For the pediatric femoral nail, the measurements of the pediatric femur were of great importance. SIGN again turned to Mimics Core to make these measurements, which in turn allowed them to make important decisions about the size of the shaft and the size of the fin, in addition to understanding the dynamics of the nail. Development is ongoing as SIGN is currently increasing the size of the nail’s shaft to give surgeons more choices.

Innovating for a brighter future in fracture care

As the physical and social damage caused by trauma continues to spread in the developing world, so does the need for SIGN’s training and implants. Fortunately, in order to not only meet this constant demand but to also improve the care they are able to provide, SIGN continues to innovate — creating new solutions as well as improving those they currently use, aided in part by Mimics. Read more success stories and see how you can help bring fracture care to the world’s working poor at signfracturecare.org.

Share on:

This case study in a few words

Healthcare

Orthopaedics

Materialise Mimics

Enabling efficient and cost-effective surgical treatments in areas with limited resources