CUSTOMER STORY

World’s Fastest Electric Racecar Breaks Record at Zandvoort by 16 Seconds

The passionate students behind InMotion had an ambitious goal — to create the fastest electric formula racecar in the world. Years of research and development led them to an outstanding achievement in the summer of 2017. At Zandvoort, the largest racetrack in the Netherlands, their IM/e racecar completed the circuit in a record-breaking 1:48.371 seconds — that’s 16 seconds faster than the previous electric lap record!

A big day at Zandvoort

Zandvoort is the most prestigious racetrack in the Netherlands, perfect for the InMotion team to test the limits of their electric racecar, the IM/e. In June 2017, the goal was simple: they intended to break the electric track record at Zandvoort, in preparation for competing at the legendary 24 Hours of Le Mans. Did they succeed? You bet they did! The IM/e performed even better than expected, achieving a time of 1:48.371 seconds in the capable hands of driver Beitske Visser.

As Arthur van der Werf from InMotion told us, “We’re incredibly excited by this result. It’s just one step closer to achieving our ultimate goal: completing the 24-hour race at Le Mans. The IM/e is an ideal testing ground for new technologies, and racing at Zandvoort is a great way to see what’s working and what needs to be changed.”

3D printing titanium parts for the IM/e

The IM/e is a test platform, which the team is using to test out systems that will eventually be incorporated in their finished product, the IM01 racecar which InMotion plans to take to Le Mans. We contributed to the suspension of the car in particular.

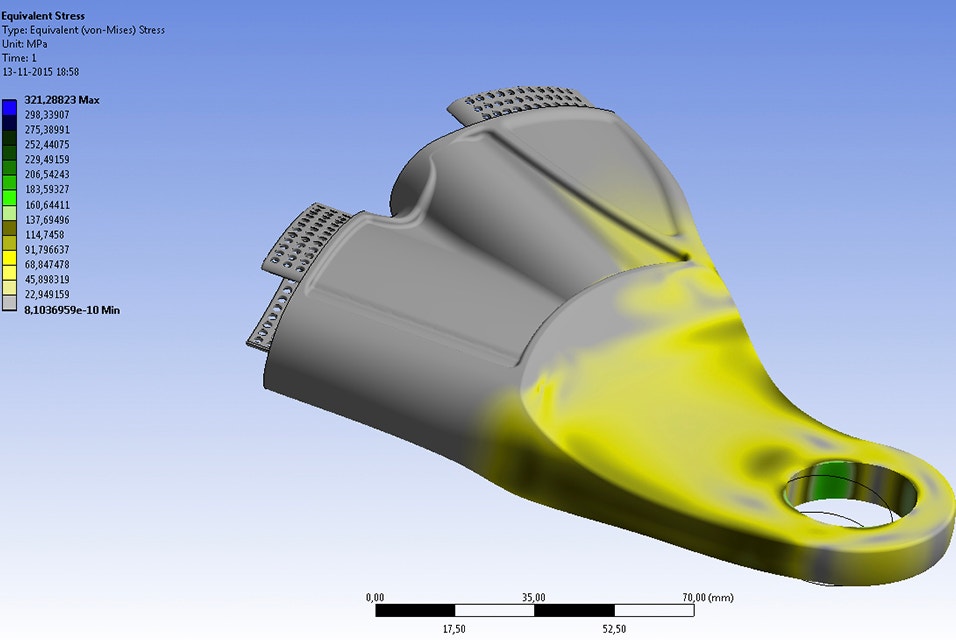

One of 3D printing’s strengths is design optimization, and when you’re creating the fastest electric car in the world, you want the structure to be as light and economical as possible. We 3D-printed the wishbones, or Y-joints, of the car in titanium — these crucial parts connect the uprights to the chassis of the car, and perform the dual job of holding the wheels in place as well as coping with all the forces the car is subjected to.

By incorporating a lightweight honeycomb structure, we reduced the weight of the suspension part while maintaining its load-bearing capacity.

The team are determined to compete at the legendary Le Mans racetrack — a grueling 24-hour race, which is tough even on a conventional racecar. But before they get there, they’ll be testing out some more racetracks to fine-tune their car’s performance. After the result at Zandvoort, we’re feeling confident about their chances!

Images courtesy of InMotion

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.