EXPERT INSIGHT

Three Big Benefits Provided by Optimal Metal Supports

In metal additive manufacturing, support structure fulfils three major functions. It has to ensure process stability (conducting heat, reducing stress and avoiding a build crash), guarantee part quality (both on a geometrical and surface level) and be as easy to remove as possible. In this blog post, we focus on process stability, which is deeply connected to quality. The three elements listed below; managing heat, avoiding deformation and reducing build crashes, are hard to separate, as not managing heat will lead to deformation, which may lead to a build crash. Keeping that in mind, let’s see what the best practices are for each element. More on support removal in our next blog!

1. Manage heat

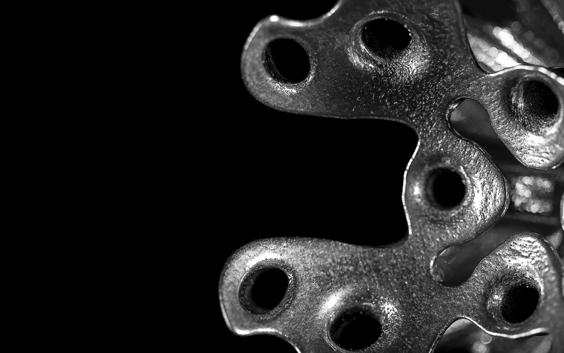

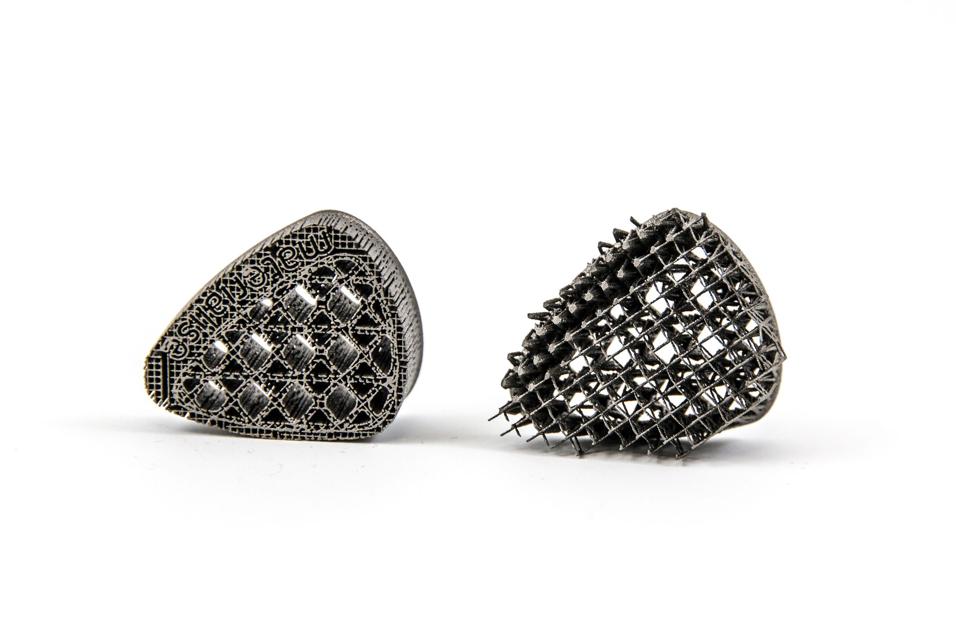

Heat can be managed both on a large and a small scale. On a large scale, heat can be conducted efficiently from the part to the build platform by using solid support structures. In Materialise Magics software, solid support structures consist of volumetric support, cones and tree support. The solid support will conduct large parts of the heat, thus reducing internal stress and deformation. To manage heat locally, it’s best to use non-solid support like block support. Block support structures look like a grid of lines, each line with the thickness of the melt pool. Small teeth attached to the part will also dissipate heat and avoid dross formation.

2. Avoid deformation

In case the heat is not completely redirected to the build platform, thermal stresses may cause deformation. This can be the deformation of the entire part (warping) or local deformation, such as the affected geometrical accuracy of holes or the appearance of shrink lines. Solid support structures will counteract deformation by anchoring the part firmly to the build platform. Non-solid support will prevent deformation locally. By changing the orientation of your part or supporting it exactly where two zones within the same slice merge and create a shrink line, you can avoid local deformation.

The Magics orientation tools help you orient parts intelligently. This can lead to a reduction of support structures, decreasing material usage and reducing post-processing work. With the orientation optimizer tool, for example, you can mark the zones of the part where they do not want to have any support structures. You are then guided to an orientation in which the zones are self-supporting.

The orientation comparator allows you to compare and analyze in-depth statistics on various orientations making it easy to choose the best fit for your needs.

3. Reduce build crashes

A powder-bed machine’s recoater system can have a significant impact on the part and its support structure during the build process, which might result in the part shifting or a collision that could damage the part and/or the recoater mechanism.

With the rescaled platform projection area tool in Materialise Magics, you can expand support structures and strengthen the connection with the platform. The teeth size, shape, penetration level and other parameters also influence the strength of the support structures. A strong connection to the platform with solid support (e.g. cones) is necessary to reduce build failures.

Metal support in Materialise Magics

There is a wide range of different support structures available in Materialise Magics, each with its own unique benefits. Depending on the geometry of your part, a specific selection will lead to the best results. For instance, cones and tree supports are particularly interesting for small, thin parts and jewelry.

Our SG+ software provides support structures using a semi-automatic process. You can set custom parameter profiles and easily tweak them afterwards when needed. You can also create your own support structures in CAD and then import them into Materialise Magics.

“The Materialise Magics SG+ Module is fascinating software that enables us to print beautiful, high-quality metal parts. The support generated by the software really satisfies our needs.”

— Sung Min Kang, Deputy General Manager at Research & Development, Daegun Tech.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.