EXPERT INSIGHT

CADSkills On What It Takes To Bring a 3D-Printed Implant Into the Hands and Jaws of Patients

CADskills is a medical device startup based in Ghent, Belgium. Their expertise lies in patient-specific implants, with a focus on CMF and neurosurgery patients. What is putting them in Materialise's spotlight however, is their AMSJI: a revolutionary 3D-printed titanium jaw implant that will make life better for extreme maxillary atrophy sufferers. Now there's something to chew on. Or with.

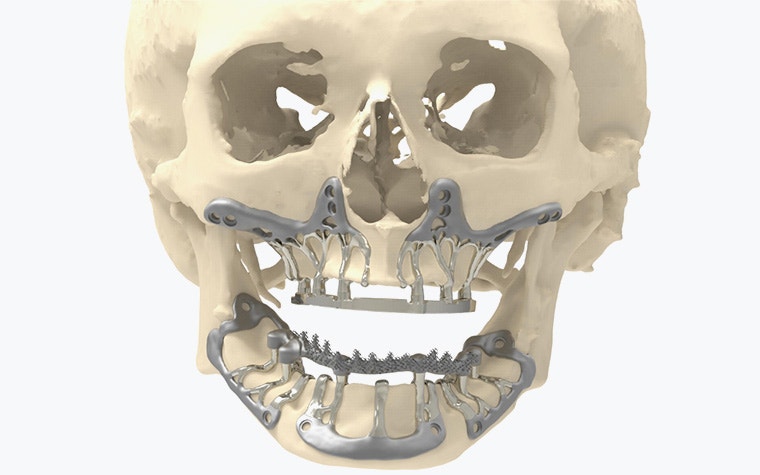

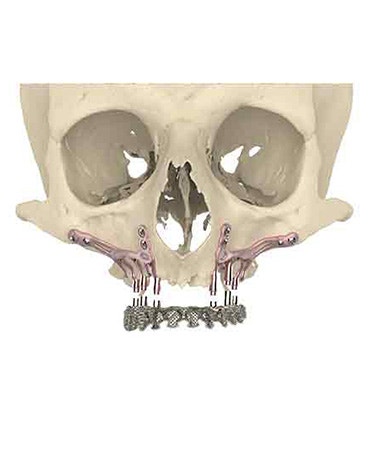

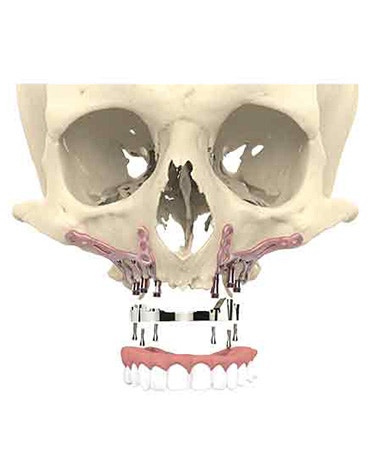

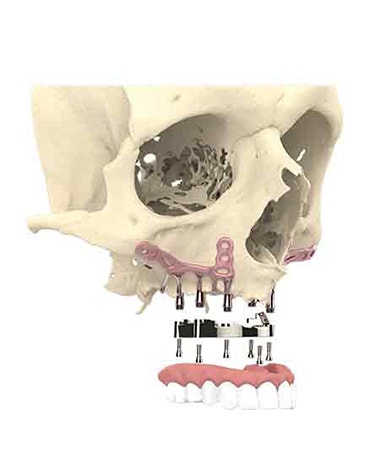

The Additively Manufactured Subperiosteal Jaw Implant, or AMSJI, devised by CADskills, originated in the mind of Prof. M. Y. Mommaerts from the University of Brussels. It's a viable alternative approach for patients with extreme jawbone atrophy, and who seek full maxillary rehabilitation, or similar treatment. The customized 3d printing implant avoids having to go through the process of bone grafting and the associated months of recovery, saves the patient from possible inflammation, takes a bite out of surgery time and provides the patient with fixed teeth the same day of surgery.

The AMSJI – Rethinking technical challenges

The AMSJI is a new generation of subperiosteal implant. It surpasses its predecessor because of the new type of material it uses now. Earlier versions were made with a cobalt-chrome alloy, a stiff material lacking in bone ingrowth properties. CADskills’ AMSJI is made of titanium and fixed by screws to provide strong primary stability. It was selected for its biocompatible properties; bone ingrowth and conductivity. Additionally, as it's 3D printed instead of being made with a lost-wax process, the design possibilities for the implant are much more extensive – including the possibility of creating porous structures – and the process is easier to control.

One of the big challenges of jaw implants is bone atrophy. When there are no longer any teeth on the maxilla, or upper jawbone, bone density will decrease and the bone will become weaker. This makes it difficult to use a classic dental implant on the patient. These patients often don’t opt for implants and settle for a removable dental prosthesis. As it's not fixed onto anything, the prosthesis can loosen or even slip out, and can cause pain. It also puts mental strain on patients, when, for example, they're trying to have a conversation without having the prosthesis falling out.

One option is to add autologous bone on the patient's jaw. However, it's invasive, and necessitates a number of operations that can collectively take up to a year. Using the AMSJI, the patient and surgeon obtain the same result in a 60-minute surgery.

Where will CADskills be in five years?

CADskills aims to become a leader in subperiosteal implants as well as patient-specific TMJ implants. They hope that the concepts they're working on will become the new standard in the CMF niche they're currently focused on.

One year ago, CADskills started with an idea, two people and Prof. Mommaerts, their source of knowledge and inspiration. Since then, their team has been steadily growing.

AMSJI hasn't reached the status of the main breadwinner in the family of CADskills' products. Yet. The company is acting responsibility by having taken on just a few cases from the beginning.

“For the past year, CADskills has studied each case meticulously and we’ve waited to see how soft tissues around the implant are reacting. We have been learning from every case and have continuously worked at perfecting the AMSJI's design for each new patient,” says Robin Detaille, COO at CADskills.

CADskills also works with orthopedic patients and are looking to explore the veterinary field. They are pursuing other concepts to improve temporo-mandibular joint prostheses and cranial plates. Now, confident that the clinical results for the AMSJI will be satisfying, CADskills is ready to hit the international market. For the next five years, one of their main goals will be to build a global network of key opinion leaders and support surgeons with their new implant.

How did Materialise Mimics support CADskills in their innovation?

For CADskills, Mimics has been fast, user-friendly, and reliable.

One of the typical issues related to replacing implants is that there are a lot of dental implants or titanium plates in patients already. This creates scattering in normal segmentation software. Mimics is very helpful in cleaning up CT scans and makes the whole process much smoother.

Another big plus for AMSJI, orbital plates and other implants, is that they can import their implant design in Mimics, and position it correctly on the 3D model of the patient’s anatomy. This makes communication with the surgeons much easier, as they get a better view in 3D of how the implant will look with the surrounding soft tissue and the positioning of the nerves. CADskills can also import screws and easily inform surgeons about the optimal screw length. In the end, this makes the surgeon feel more confident about using their products.

Finally, they also chose Mimics because of its certification and long history in many pre-surgical planning innovations. In order to have a validated quality system, a lot of administrative work and proof is required. As Mimics is already certified, documents for that purpose already exist.

And as for CADskills’ favorite feature in the software? Multiple slice edit is their winner. It speeds up the whole process. It's intuitive, accurate, there's no need to edit each slice and some can even be skipped.

Would CADskills recommend Mimics?

“Definitely. Compared to competitors, Mimics' speed is magnificent,” as Ruben Van de Sande from CADskills explains.

“It's also stable, reliable and certified. The Materialise Mimics support team are fantastic – they are incredibly fast at solving problems and we know we can rely on them. Another upside to Mimics is that it's user friendly which makes it very easy to train new employees to use it.”

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.