CUSTOMER STORY

Taking End-Use Additive Manufacturing All the Way to the TCT Awards

Partnering with Viridian Consultants, the Quigley Design team demonstrated the power of additive manufacturing for end-use products with a complex, highly innovative tool for nuclear decommissioning that saw them nominated for a coveted TCT Group design award.

“When you’re a designer, you’re only as good as the projects that come along for you to do.” Designer Kevin Quigley may be as modest as he is talented. He and his Quigley Design team collaborated with Viridian Consultants on a new design that demonstrates the power of additive manufacturing, not just for prototypes, but in end-use products. A collaboration that earned them a nomination in the Industrial Product Application category of the TCT Group’s annual design awards.

Innovating a faster, safer nuclear decommissioning system

Nuclear decommissioning is tricky and dangerous work. When a nuclear facility is shut down, a painstaking process is initiated to dismantle the facility and clean up any remaining nuclear material so it no longer poses a threat to safety.

This process requires a lot of sampling to determine the radiation levels contained within various materials at a site, and traditional methods are very labor- and time-intensive, often involving breaking parts down physically and sending them back to a lab for testing.

Viridian Consultants — experts in instrumentation solutions for the nuclear sector — saw an opportunity to improve this process. In collaboration with Quigley Design — a product design and development company out of Shrewsbury, United Kingdom — they created the game-changing ViridiScope system.

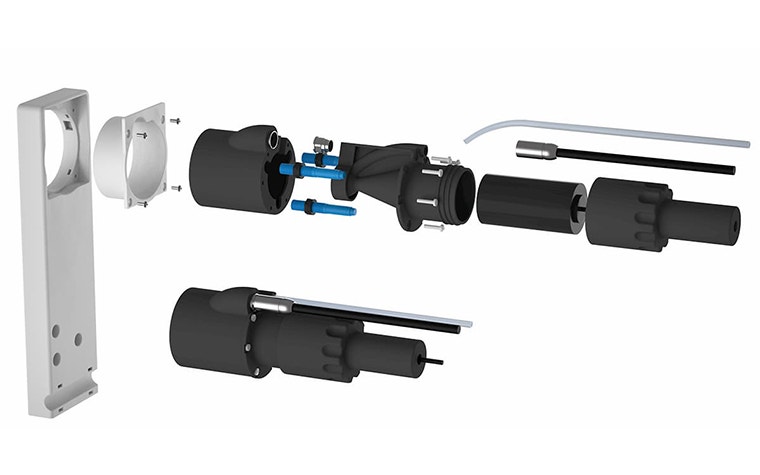

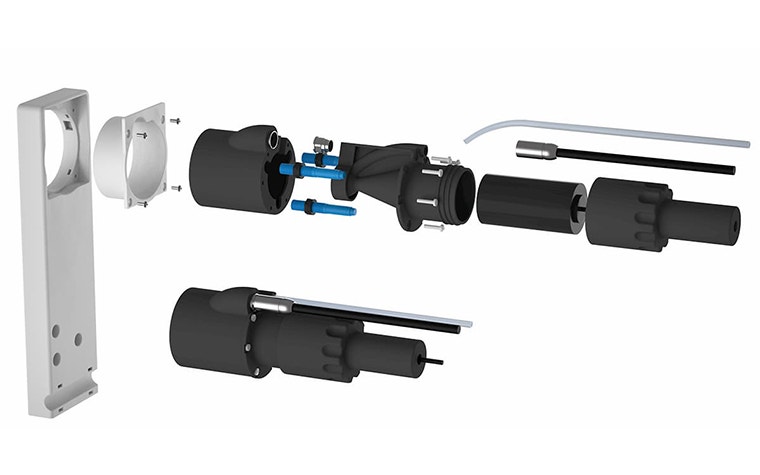

The ViridiScope is a nuclear characterisation sensor that brings an entirely new approach to sampling for nuclear decommissioning. Designed to operate on a remotely operated vehicle (ROV), the ViridiScope can climb walls and enter areas difficult for humans to access.

“This particular project was actually ideal for [using 3D printing] because it was a low-volume, high-value product and it had to be nylon because of the nuclear disposal route.”

— Kevin Quigley, Founder of Quigley Design

Using a sampling head housed within a 3D-printed exterior, the scope takes material samples directly from solid surfaces, reducing the sampling time for 100 samples from four to six days down to just four hours. The ViridiScope was also designed to integrate with on-site sample preparation and analysis, allowing samples to be analyzed instantly, giving a real-time measure of the radioactivity present in the material and immediate feedback to site teams, saving months of wait time.

Creating the perfect fit and function with additive manufacturing

To ensure the product worked exactly as the decommissioning staff needed it to, several versions of the scope were created, all with multiple intricate parts that needed to fit together precisely to securely hold the electronic and optical systems and allow it to operate in tight spaces.

“We really couldn’t have done the project if we hadn’t have used [additive manufacturing]. We designed it for AM right from the start.”

— Kevin Quigley

As Quigley emphasizes, “This particular project was actually ideal for [using 3D printing] because it was a low-volume, high-value product and it had to be nylon because of the nuclear disposal route. When you actually go into a hot area, there are only certain materials you can take in to actually be disposed and nylon was one of those materials, so that’s why we had to use selective laser sintering.”

And because of the use of 3D printing, as each iteration of the scope was tested, pieces could be tweaked and improved quickly, with no stop point in development.

“It’s been a good project to demonstrate the application of end-use additive manufacturing and it’s a very diverse project — it’s not one or two parts, the whole system was done using AM and we really couldn’t have done the project if we hadn’t have used it. That’s the big difference [from our usual projects]. We designed it for AM right from the start.”

Parts as you need them, when you need them

When performing proof of concept work, it can be very difficult to make changes to your design as you go, and the cost is often prohibitive to not getting it right the first time. That’s why Quigley chose to use Materialise OnSite for this project.

OnSite, Materialise’s online 3D printing service for professionals, was designed to help customers with time-critical projects. Dedicated fast-lane machines ensure short lead times for a wide range of technologies and materials.

By choosing to use additive manufacturing, Viridian saved approximately £200,000 in total production costs and reduced their time-to-market by almost three years.

“OnSite’s got a good system in the sense that there’s an option for rush laser sintering jobs, which is two days, and they’ve also got next-day stereolithography. Laser sintered parts are hard to get a hold of fast, most times it takes about five days and it’s quite a challenge to get them back any quicker than that.”

OnSite’s instant quoting feature also allowed Quigley to provide their clients with a ballpark figure for pricing. By choosing to use additive manufacturing for the development of the ViridiScope, Viridian saved approximately £200,000 in total production costs and reduced their time-to-market by almost three years.

As additive manufacturing is becoming more important and integrated into manufacturing in an end-use capacity, we are thrilled to see Quigley and Viridian Consultants’ innovative design nominated for the TCT Industrial Product Application Award 2019, showcasing the possibilities and advantages the technology has to offer.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.