INTERVIEW

"Aha!": When People Can See What’s Possible and Practical with Additive Manufacturing

In this interview, we talk to Jurgen Roekens, Materialise’s Design and Engineering Director, about how the Design for Additive Manufacturing (DfAM) process helps his clients produce exactly the right engineering solution that adds value in many different ways.

Welcome Jurgen. 3D Printing for manufacturing is becoming more mainstream – does that mean customers have more design expertise in-house?

They do. We work with some very talented teams. However, a lot of expertise is still based around prototyping. Consequently, while many customers have the skill and appetite to design their own parts internally, they can struggle to take that initial concept through to manufacturing and so come to us for help in creating a CAD model or optimising an existing model to make it fit for serial AM production. What we do see time and time again is that in-house expertise plus external specialist knowledge is a powerful catalyst for creative, and ultimately more effective, design. The earlier we start working with a customer the better in this respect.

Why is that exactly?

Our position as an "objective outsider" and 3D printing expert means – right from the word go – we are thinking about options for AM. The possibilities and the constraints. Paired with the product, sector and engineering knowledge our customers hold, this means we can often come up with completely new solutions to leverage more added value from AM.

Design options regularly emerge during the early stages of our Design for Additive Manufacturing (DfAM) process that customers never even knew were possible. Smart solutions that can only be produced using AM, like printing a hinge as a single piece instead of multiple components that must be assembled.

Similarly, getting involved early means we are in the perfect position to make customers aware of solutions that do already exist, often in entirely different sectors to their own, in order to avoid "re-inventing the wheel". When customers can see exactly what’s possible and practical with additive, it leads to that “Aha!” moment.

You mention leveraging “added value” through design. How do you make sure these opportunities are always maximised for your customers?

Value engineering traditionally balances cost against functionality or performance, but we think that is a little narrow. For us, there should always be two more factors in the mix.

Interface is one. Improving how a component fits into the overall design, links with other components as part of a system, or fits with the user’s body. Is it going to be easy to assemble with the other parts? Will customised eyewear match your face or will the 3D-printed insole fit your foot? These are key questions – 3D printing is ideally positioned to answer in a range of innovative ways.

Conversely, added value also comes from minimising the negative impact on the user or other components. In other words, minimising "harm". Harm can be an ecological consideration like avoiding wasting material. Very often it comes down to weight reduction and/or improved ergonomics, with the ultimate goal being a harmless solution – one that has no negative impact on user, system, or environment.

So a design’s greatest "added value" comes from maximising performance and interface while minimising cost and harm. Bringing those metrics into the added value equation makes the end solution much more powerful than simply focusing on function and cost alone.

Do you always look at these factors during the early stages of the design process?

Yes. It gives you areas to explore with customers – four anchor points if you like – which will always guide discussions towards an optimal outcome.

How does that work? We’ll start by looking at the specific goals for the new design. Does it have to be customised to fit different users or applications? Is it a full-size prototype of a new product? Or a lightweight version of an existing part for series production – which is one of the most common requests we receive.

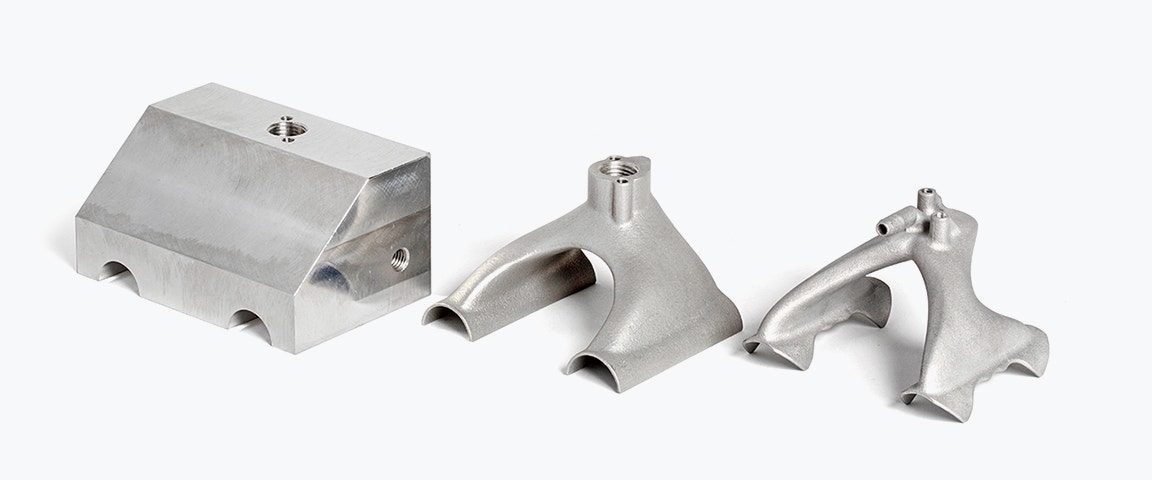

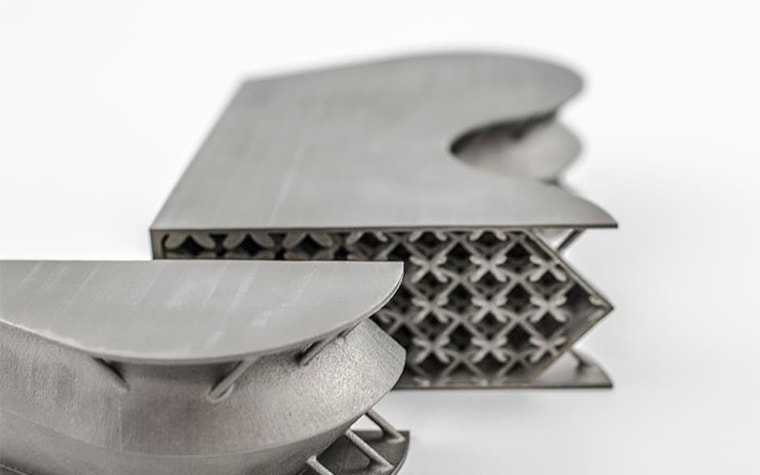

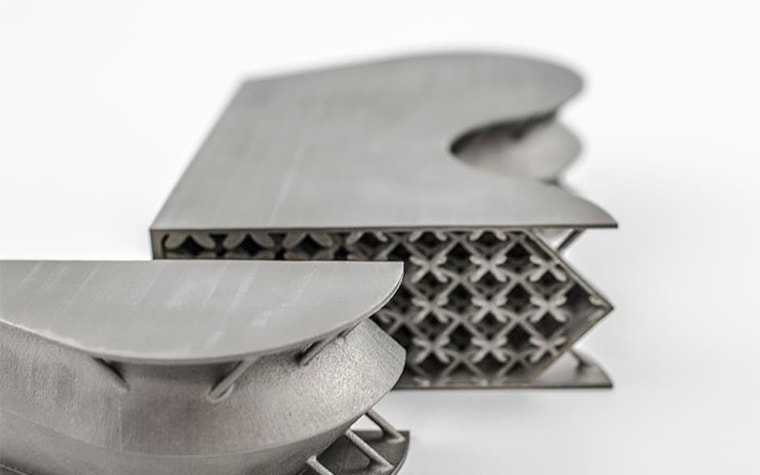

With AM’s design freedom you can optimise the topology and incorporate internal lattice structures to lightweight the hell out of metal parts, without compromising the strength, thermal resistance and so on, in a way you just can’t with traditional approaches like casting. So, if we match the current performance through AM but lower the weight, cut costs and improve the interface, then that is very much a win.

That’s what happened when we worked with Volvo to build a gluing jig used to align car badges on the production line. With the required 0.2mm tolerance, our design matched the performance of the previous welded aluminium jig but cut weight by 64% so it’s much easier to manipulate, reducing harm to the users. The guys on the line certainly don’t want to go back to the old solution. On-demand printing removed the need for expensive stock and the solution can easily be customised to fit any other car, so the interface is excellent too.

Great – could you give us another example where DfAM ‘ticked’ all four metrics?

The satellite insert we designed with ATOS is a good example. A 66% weight reduction that cut the launch costs by €20,000/kg. Thanks to topology optimisation and AM’s design freedom, this metal part was also stronger with tighter tolerances – so performance increased – and its shape helps hold structural panels together more effectively, so its interface is great as well.

Another project involved redesigning a metal production line suction gripper. Through DfAM, we made it faster to manufacture with a 70% lower cost. We combined the six parts they were using into one and cut weight by 75%.

Have you been involved in the early phases of any other production line tooling projects?

In a project with Philips to create a new metal bracket, we were involved right from the start and were able to create a truly holistic solution that again delivers in all those four areas of added value. Improving on the previous unreliable design was a priority and Philips thought that, at best, they would have to replace our design less often but in fact, there is just no part failure at all. That saves thousands of euros a year on maintenance technician hours but with no production line downtime, the cost benefit becomes huge.

Interface-wise, the bracket used to be assembled from four parts but now it’s printed as one metal component. From a harm point of view, we can produce the part just in time with the minimum amount of material so Philips don’t need to be milling metal parts or holding stock.

Is there a magic ingredient to ‘turbo charge’ the DfAM process with customers?

Obtaining different viewpoints is hugely beneficial. It’s not magic, but it is the most effective route to the best outcome.

During the exploration and concept development stages, we interview customer staff and run workshops, encouraging ideation and creating visuals that help them assess candidate solutions. The people looking at costs are very often in purchasing, but on the factory floor, the people who are actually working with the components will have different goals like safety, ergonomics, and working conditions.

Applying these varied viewpoints and using them to look at our four metrics in isolation is a really good springboard; you can design against each one and then look at how those four if you like, partial solutions, can be combined into one holistic design.

It’s very satisfying to be able to help customers consider and visualise all the different options, they can see where each part of the solution comes from and why. Ultimately this helps them be confident that their application is right for AM.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.