EXPERT INSIGHT

3 Ways Virtual Reality Can Supplement Your Medical 3D Printing Activities (And 3 Ways It Won’t)

Medical 3D technology has a wide range of applications, but when 3D modeling is confined to a 2D computer screen, crucial benefits can be lost. In situations where printing 3D models is not feasible, 3D visualization in virtual reality can unlock many of those benefits.

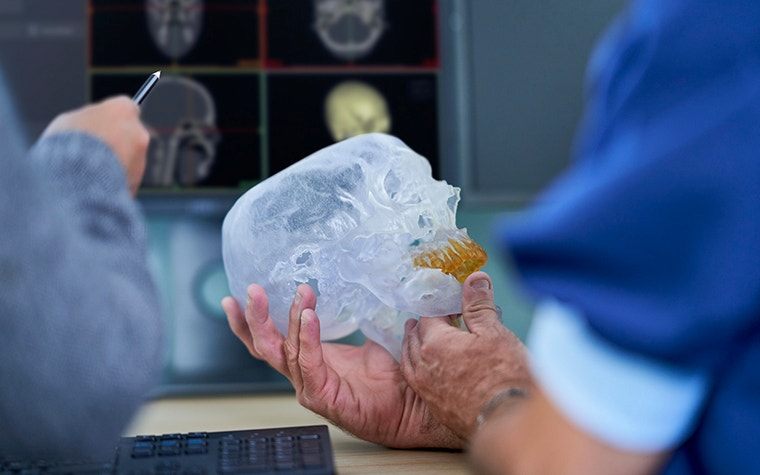

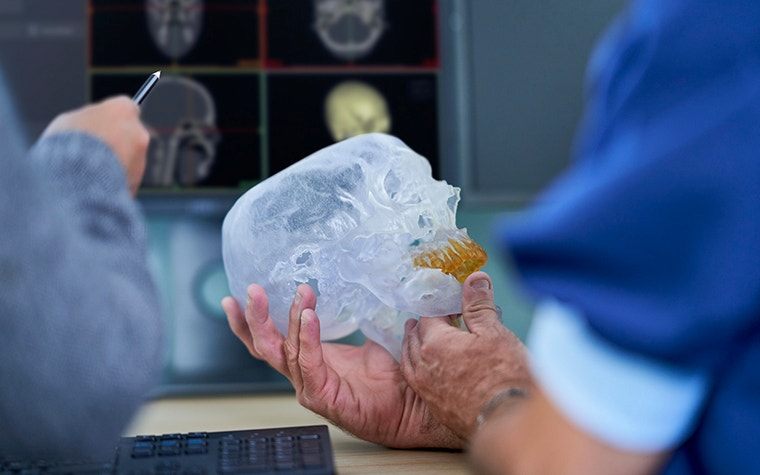

There’s no doubt that medical 3D technology is here to stay, whether it’s for training and education, patient communication, device development, research, or pre-surgical planning. But 3D modeling happens on a 2D computer screen. Leaving it there would be missing out on the crucial benefits of designing 3D models, like the ability to visualize CT and MRI data in a form that’s closest to life.

The obvious solution is 3D printing, an answer that an exponentially increasing number of US hospitals have embraced, as we saw in the rise of hospital-based 3D printing facilities in 2010 – 2016. On the other hand, printing anatomical models is best suited for individualized cases, like patient-specific pre-surgical planning, where a single model needs to be produced. For applications like training and education, several trainees need access to the same models. Mass production is not the best application for medical 3D printing, nor is it an efficient approach. The solution? Visualization in virtual reality (VR), as a supplement to 3D printing.

VR tools have taken the gaming world by storm, but an application that keenly interests Materialise is the potential of virtual reality for multidisciplinary collaboration and education. And there are three big reasons why we see medical applications as one of the top beneficiaries of this technology.

1. It’s cost-efficient

Regardless of how many students need access to the model or where they’re physically located during the demonstration, the cost of scaling virtual models is virtually zero. As a result, hospitals are able to bring the benefits of 3D modeling to an ever-increasing number of trainees while keeping the cost per case low.

Using VR for training purposes would allow hospitals to deploy their 3D printing budgets more strategically for applications where 3D printing can stand to make a meaningful difference, such as in preoperative planning and implant placement preparation.

2. It’s fast

3D printing is a famously fast production technology compared to conventional manufacturing. But translating data from 3D modeling software into a VR environment is even faster. In an educational context, this is ideal as trainers can demonstrate changes on the 3D model in real time. Users of 3D modeling software like Materialise Mimics will also benefit from being able to repurpose the same data in the VR environment.

Nils Faber, Concept Development Engineer at Materialise, has been working closely with our clinical engineering team to create a VR environment where clinicians can interact with patient-specific anatomical models and use them for live demonstrations.

“Next to 3D printing, virtual reality is the only technology that allows you to view any patient’s anatomy in real size and interact with it in real time,” explains Nils. “That makes VR the perfect classroom complement to a 3D printing lab.”

3. It’s true to life

For hospitals with point-of-care 3D printing labs, the quality of 3D-printed models often depends on the printers and materials available. This can translate into a loss of detail when color and texturing suffer as a result of the limited availability of printing materials.

“With VR, the stereoscopic 3D view allows for a better understanding of the structures, just as you would with a 3D-printed model,” says Nils. “What you see is what you get, really. This makes VR the ideal solution for demonstrational and training environments where visual information is more critical than the haptic feedback and sense of scale that 3D printing excels at.”

The flipside of virtual reality

To put it simply, VR can’t replace your sense of touch. VR cannot replicate the nuances of the haptic and tactile feedback you get from holding an exact 3D-printed replica of a patient’s anatomy in your hands. For this reason, we don’t expect VR to replace 3D-printed anatomical models in the role of preoperative planning.

Similarly, virtual reality doesn’t convey the same sense of scale that a life-size 3D-printed replica does. While this still works for visualization purposes, it becomes a handicap for applications like preoperative planning unless a 3D-printed model is also available.

Besides, VR devices can be non-intuitive for new users to navigate. Even though interacting with the 3D model follows an easy learning curve, particularly for those used to working with 3D modeling software, operating the hardware is unlikely to become a mainstream competence in the next few years.

“Like all tools, the success of VR depends on its suitability for a given application. Is VR the tool of the future for hospitals? I strongly believe it has a lot to offer; that’s why we’re investing in exploring VR for medical training purposes. But its real strength comes when VR is a complement to 3D printing rather than a tool used in isolation,” concludes Nils.

L-102932-01

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.