Technology

Selective Laser Sintering

Get high-quality polyamide and polypropylene parts quickly — even those with the most complex geometries. Our ISO-certified selective laser sintering 3D printing services deliver high precision and a wide range of production-grade polymers to meet your requirements throughout the production lifecycle.

Selective laser sintering 3D printing service

Count on our ISO-certified facilities and processes to bring even the most complex designs to life. Choose from a wide range of polyamides and finishing degrees and feel the benefits of more than 35 years of 3D printing experience from design to series production.

Need quality parts fast? We’ll have your order shipped in as little as 48 hours with our Fast Lane service.

What is selective laser sintering used for?

Technical specifications

| Maximum build dimensions | Dimensions are unlimited as components may be composed of several sub-parts. The maximum build envelope is 630 x 330 x 550 mm |

| Standard accuracy | ±0.3% (with a lower limit on ±0.3 mm) |

| Layer thickness | 0.12 mm |

| Minimum wall thickness | 1 mm, but living hinges are possible at 0.3 mm |

| Surface structure | Unfinished parts typically have a grainy surface but various post-production finishes are possible |

Selective laser sintering materials

Choose from a broad selection of materials when you come to Materialise for your laser sintering projects.

PA 12 Medical-Grade (PA 2201)

Technology

Selective laser sintering

Description

PA 12 Medical-Grade offers high strength, chemical resistance, and detail resolution, making it ideal for high-quality and fully-functional biocompatible plastic parts for settings such as operating rooms. This material is subjected to testing for cytotoxicity, sensitization, irritation, acute systemic toxicity, and material-mediated pyrogenicity.

Key characteristics

- Biocompatible material

- High strength and stiffness

- Good chemical resistance

- High selectivity and detail resolution

- Max part dimensions: 170 x 215 x 320 mm

PA 12 (SLS)

Technology

Selective laser sintering

Description

PA 12 (SLS) is a general-purpose material that offers excellent long-term stability and good chemical resistance, making it suitable for functional prototypes and end-use parts, as well as consumer goods.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High strength and stiffness

- High chemical, mechanical, and thermal resistance

- Fast Lane service available for online orders of PA 12 (SLS) – Normal finish

- Max part dimensions: 630 x 330 x 550 mm

- Max part dimensions (Fast Lane orders): 270 x 270 x 270 mm

PA-AF (Aluminum Filled)

Technology

Selective laser sintering

Description

PA-AF blends polyamide with aluminum to produce strong, stiff parts resistant to temperatures of up to 130°C. With a metallic appearance, it is ideal for models, rapid tooling, and fixtures.

Key characteristics

- Strong, stiff material printed without a support structure

- Slightly sparkly metallic appearance, suitable for post-machining

- High temperature resistance (130°C)

- Max part dimensions: 630 x 330 x 550 mm

PA-GF

Technology

Selective laser sintering

Description

PA-GF blends polyamide with glass beads to offer higher durability, stiffness, and thermal resistance. It is ideal for prototypes or applications where temperature or wear resistance are key.

Key characteristics

- Strong, stiff material printed without a support structure

- High tensile strength, wear resistance, and temperature resistance (110°C)

- Suitable for post-machining

- Max part dimensions: 630 x 330 x 550 mm

Polypropylene (PP)

Technology

Selective laser sintering

Description

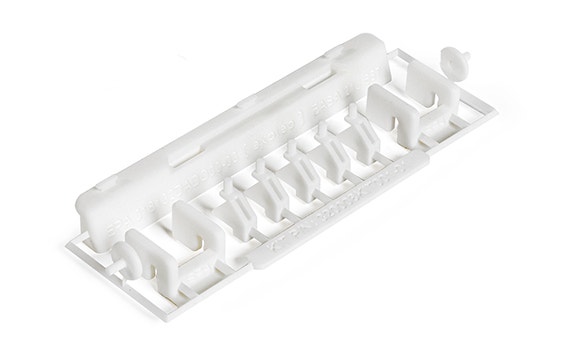

A tough, fatigue-resistant, and lightweight material, polypropylene (PP) is ideal for functional prototypes of snap-fit assemblies or living hinges in automotive components, packaging, and consumer goods.

Key characteristics

- Tough yet flexible material printed without a support structure

- Very high elongation at break (> 500%)

- Lightweight and fatigue resistant

- Max part dimensions: 480 x 480 x 430 mm

PA 2210 FR

Technology

Selective laser sintering

Description

PA 2210 FR is a high-performance, UL Blue Card-certified polyamide containing a halogen-free flame retardant. Excellent long-term stability and good chemical resistance make it ideal for functional prototypes or end-use parts.

Key characteristics

- Strong material printed without a support structure

- Flame retardant — UL Blue Card-certified (UL 94 rating of V-0 at 3 mm wall thickness), CS/FAR 25.853 compliant

- High chemical, mechanical, and thermal resistance

- Max part dimensions: 280 x 280 x 550 mm

PA 2241 FR

Technology

Selective laser sintering

Description

PA 2241 FR is a high-performance, flame-retardant polyamide. Its excellent long-term stability and good chemical resistance make it ideal for functional prototypes or end-use parts.

Key characteristics

- Strong material printed without a support structure

- Flame retardant — CS/FAR 25.853 compliant, available in Airbus certified grade, according to AIPI 03-07-022

- Excellent long-term stability and high chemical resistance

- Max part dimensions: 630 x 330 x 550 mm

Work with us: discover our products and services

Want to bring laser sintering into a future project? Discover the 3D printing services that can help you do it.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Train and learn

Get more from your next project with helpful resources dedicated to selective laser sintering.