Materialise Magics

The most powerful 3D data and build preparation software

Simplify and optimize data and build preparation with Magics — our comprehensive, industry-leading 3D printing software — with both CAD and mesh tools. Gain advanced control over your processes, automate repetitive tasks, and increase print success rates — supporting you no matter which 3D printing technology you use.

Why Magics?

Advanced control over workflows

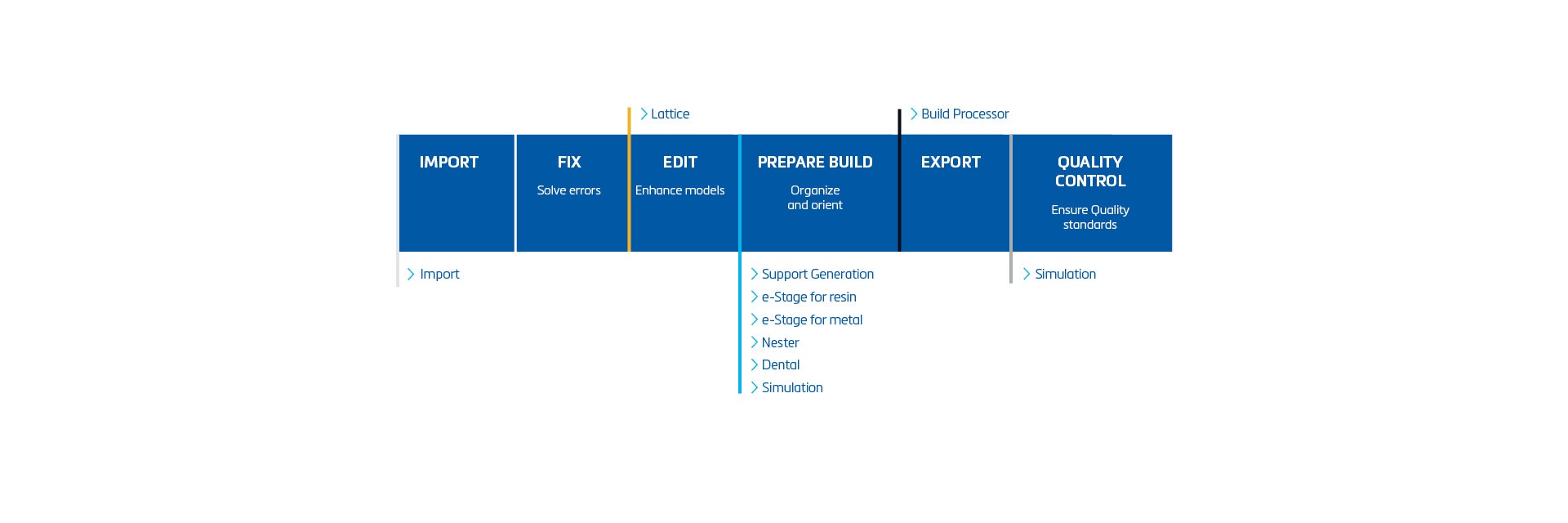

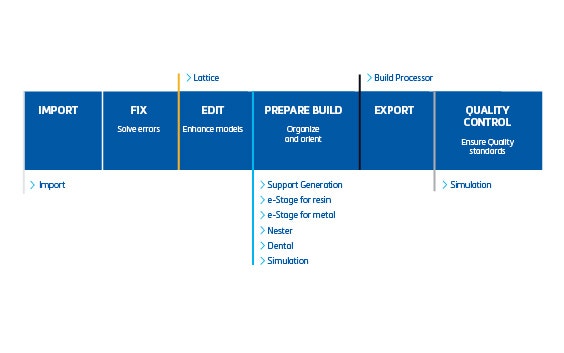

Import files, edit, cut, and label parts, create lattices and supports, optimize nest density, slice models, simulate metal builds, and more in one software environment.

Optimize and automate repetitive tasks

Reduce lead times, human error, and excessive manual effort with workflow automation software for support generation, nesting, labeling, and simulation.

Robust integrations cover your entire workflow

Experience enhanced additive manufacturing traceability and connectivity by linking Magics with our CO-AM Software Platform, offering insights into revisions and more. Plus, manage basic machine parameters with Machine Manager.

Dependable support

From training courses to our Help Center to personalized advice, our team of experts is here to help you. Learn to embed Magics into your processes, optimize your use of Magics, and get the most out of its features.

Technology neutral

No matter the technology or materials you use, you deserve one solution to meet all your needs.

Key features — from import to print

Import data types and formats

Import nearly all relevant file formats, retain native color information, and stay in control of your original data.

Fix, edit, and enhance

Leverage both CAD and mesh (STL) editing tools to ensure high-quality, printable parts with tools like automatic fixing, offsets, and lattice structures.

Optimize nesting

Nest parts with speed and control using tools that range from manual to fully automatic in the Nester module.

Automate support generation

Optimize the speed and process of support generation with Magics modules tailored to specific 3D printing technologies.

Analyze builds

Avoid costly build failures and reduce scrap rate using analysis features that detect potential issues.

Transfer designs to your machine

Slice builds with precision and communicate clear building instructions to your printer with our Build Processors.

Generate reports

Extract nearly any parameter from Magics to keep track of builds and ensure repeatability with fully customizable automatic reports.

Magics modules that suit your AM workflow

Find the modules for your technology

Optimize metal support and heat transfer to avoid detachment or warpage with a combination of non-solid and solid structures.

Identify error-prone areas of your build before printing so you can get it right the first time, every time.

Automatically generate metal support structures to reduce human error and save time during build prep and support removal.

Reduce weight, preserve strength and stability, or make parts more porous to ensure optimal performance.

Bridge the gap between CAD software and 3D printers by importing nearly all standard CAD formats.

Quickly and easily prepare high-quality metal crowns, copings, bridges, and partial bases for printing.

Generate thin support structures with minimal contact points to prevent deformation, facilitate heat transfer, and improve surface quality.

Nest parts quickly and efficiently to maximize build capacity, protect small pieces, and reduce human error.

Reduce weight, preserve strength and stability, or make parts more porous to ensure optimal performance.

Bridge the gap between CAD software and 3D printers by importing nearly all standard CAD formats.

Nest parts quickly and efficiently to maximize build capacity, protect small pieces, and reduce human error.

Reduce weight, preserve strength and stability, or make parts more porous to ensure optimal performance.

Bridge the gap between CAD software and 3D printers by importing nearly all standard CAD formats.

Automatically reinforce your parts with customizable, non-solid support structures to reduce SLA build failures and optimize part quality.

Bridge the gap between CAD software and 3D printers by importing nearly all standard CAD formats.

Nest parts quickly and efficiently to maximize build capacity, protect small pieces, and reduce human error.

Reduce weight, preserve strength and stability, or make parts more porous to ensure optimal performance.

Automatically reinforce your parts with customizable, non-solid support structures to reduce SLA build failures and optimize part quality.

Automatically generate resin support structures to reduce human error, decrease material consumption, and save time during build prep and support removal.

Bridge the gap between CAD software and 3D printers by importing nearly all standard CAD formats.

Reduce weight, preserve strength and stability, or make parts more porous to ensure optimal performance.

Generate thin support structures with minimal contact points to prevent deformation, facilitate heat transfer, and improve surface quality.

Automatically reinforce your parts with customizable, non-solid support structures to reduce SLA build failures and optimize part quality.

Automatically generate resin support structures to reduce human error, decrease material consumption, and save time during build prep and support removal.

Bridge the gap between CAD software and 3D printers by importing nearly all standard CAD formats.

Generate thin support structures with minimal contact points to prevent deformation, facilitate heat transfer, and improve surface quality.

Reduce weight, preserve strength and stability, or make parts more porous to ensure optimal performance.

Bridge the gap between CAD software and 3D printers by importing nearly all standard CAD formats.

Offers supports for two technology types: stands during heat treatment of binder jet parts and stabilization walls for parts made using extrusion technologies.

Reduce weight, preserve strength and stability, or make parts more porous to ensure optimal performance.

Bridge the gap between CAD software and 3D printers by importing nearly all standard CAD formats.

Offers supports for two technology types: stands during heat treatment of binder jet parts and stabilization walls for parts made using extrusion technologies.

Reduce weight, preserve strength and stability, or make parts more porous to ensure optimal performance.

Learn about Magics

Access training, tutorials, customer support, and more information on using our software with the following resources.

Frequently asked questions

Discover how others use Magics

Related products & services

Generate lattices, create textures for an aesthetic finish, and achieve post-topology optimization.

Automate data and build preparation workflows to prevent human error and boost efficiency.

Slice and send jobs to 3D printers based on machine-specific strategies or optimize custom scan path strategies with our software development kit.

Centralize order requests, ensure on-time delivery, and streamline pre-print workflows with the Magics integration.

Plan and manage the entire AM process to maximize throughput, optimize capacity, and gain complete visibility across your operations.

Connect 3D printers and auxiliary equipment to the cloud to monitor real-time sensor data with alerts and ensure production parameters meet specifications.

Track non-conformances and CAPA reports to drive continuous improvement and meet regulatory compliance.

Leverage business intelligence to gain insights, drive demand, optimize costs, and enable sustainable growth plans while de-risking AM deployment.