Production Tooling

Supercharge your production line

Has your productivity hit a plateau? Through additive manufacturing at Materialise, you can produce the jigs, fixtures, assembly aids, and other crucial tools you need to evolve, enhance, and de-risk your production lines. By maximizing uptime, reducing costs, and embracing flexibility, you can break through the productivity barriers slowing you down.

Why choose 3D printing?

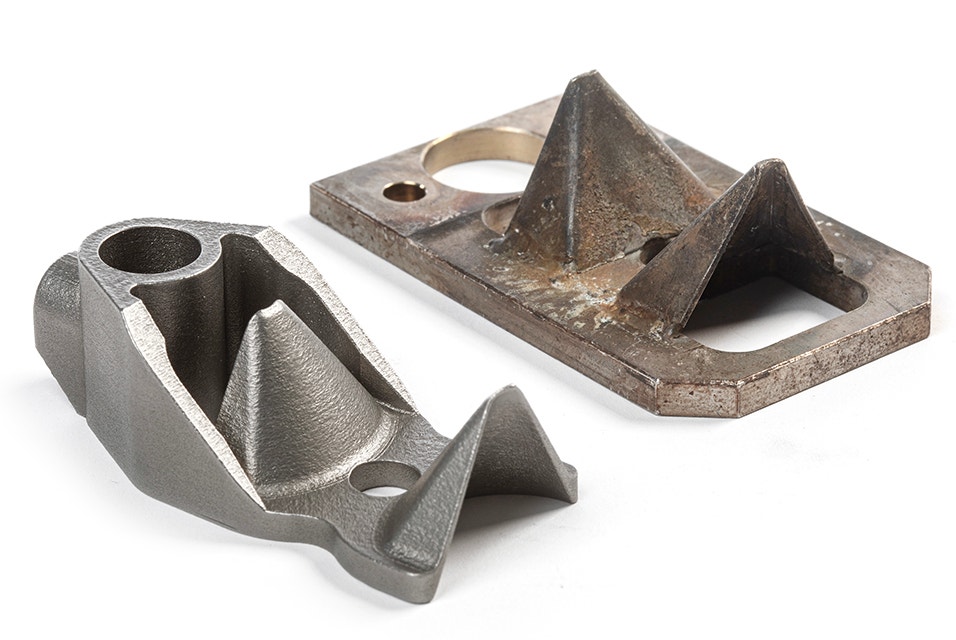

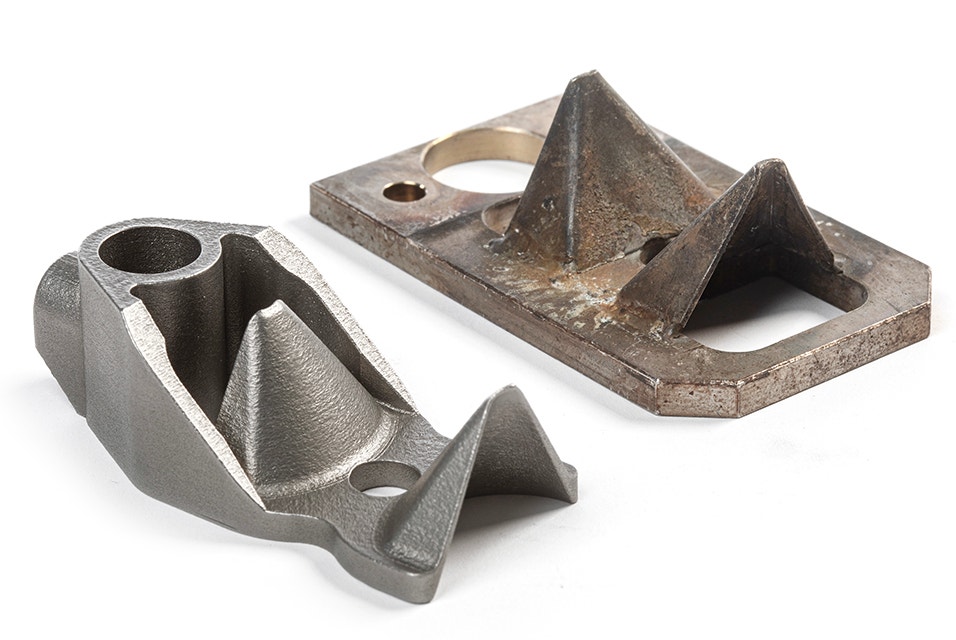

Improve part performance

Design freedom allows you to design-in functionality or create complex structures. With design for additive manufacturing, you can optimize the internal channel flow of liquid or air, lower downtime and maintenance costs from failing components, or reduce weight to decrease cycle time.

De-risk supply chains

Reduce risk and reap the rewards — reduce lead times and unnecessary stock storage with additive manufacturing. By manufacturing on-demand from a digital inventory, you get only what you need when you need it, avoiding the risks of waste, obsolescence, and delays.

Increase efficiency

Work smarter, not harder. With the added efficiency of additive manufacturing, you can improve the performance of parts and machinery and optimize uptime — reducing costs and increasing the speed of your cycles.

Focus on innovation

With 3D printing, you have the freedom to do things differently. Find the niche that sets your product apart, provide something unique and customized for every customer, react to changes in the market quickly and easily, and improve your offering with every iteration.

Our services for production tooling

Ready to start your project with us? Discover our services, ideal for your application.

私たちのエキスパートとのコラボレーションで、ものづくりを革新し、スピードアップしてください。あらゆる産業、用途に対応する充実の自社技術にお任せください。

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

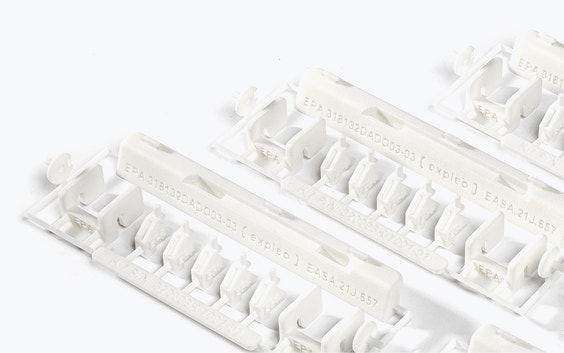

Through expert knowledge of engineering, 3D printing, and software development, the RapidFit team provides jigs, fixtures, and tools for the automotive industry that save costs, time, weight, and space.

Production tooling success stories

Discover how additive manufacturing helped these companies improve their productivity.

Inspiration

Get inspired for your next project with a look at how others have benefited from 3D-printed production tooling.