Servicios de impresión 3D

Desde la creación de prototipos hasta la producción de pequeñas series.

Tanto si su producto es único como el primero de muchos, puede confiar en Materialise Manufacturing. Nuestros servicios de impresión 3D industrial ofrecen un rápido desarrollo de productos y una innovadora fabricación digital, desde el concepto hasta la ejecución. Confíe en nuestros medios e instalaciones de fabricación aditiva, líderes en el sector, y en nuestra experiencia inigualable para acelerar su proyecto de fabricación aditiva hoy mismo.

Obtenga acceso directo permanente a las tecnologías y materiales que necesita para convertir sus diseños en realidad. Presupuestos instantáneos, rápidos plazos de entrega y sistema de pago sencillo.

Innove y acelere su fabricación en colaboración con nuestros expertos. Confíe en nuestra completa gama de tecnologías propias adecuadas para todos los sectores y aplicaciones.

Transforme su ciclo de desarrollo de productos y consiga que los mejores productos salgan al mercado de una forma más rápida. Obtenga un asesoramiento realmente imparcial y un apoyo dedicado de equipos comprometidos con su éxito.

Aplicaciones

¿Por qué elegir Materialise Manufacturing?

Una amplia selección de servicios, tecnologías y materiales

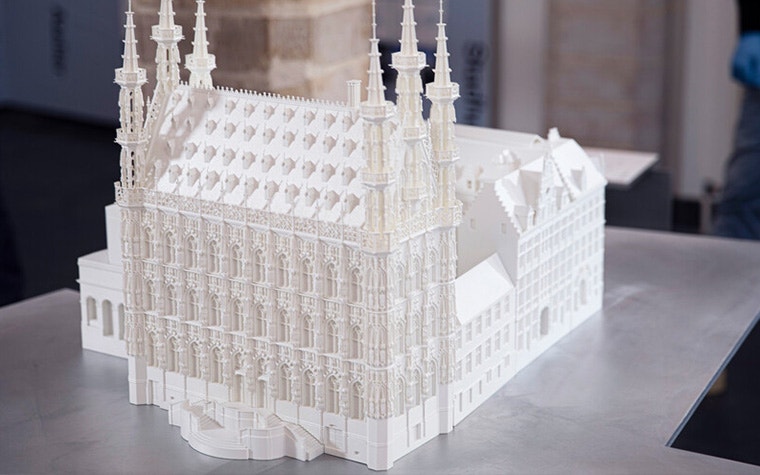

Cuando trabaje con Materialise, tendrá acceso a mucho más que la mayor fábrica de impresión 3D de Europa y una increíble selección de tecnologías, materiales y acabados. Encontrará líneas de fabricación especializadas y servicios de creación de prototipos listos para usar, además de nuestra experiencia en diseño para fabricación aditiva y servicios de consultoría. Todo esto en el mismo lugar y con la facilidad de manejar un único proveedor.

Garantía y control de calidad

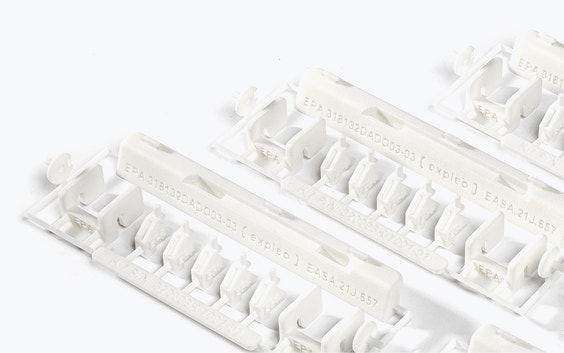

Desde nuestro sistema de gestión de calidad con certificación ISO 9001 hasta nuestras certificaciones ISO 13485 y EN9100, garantizamos que nuestras instalaciones y procesos cumplen las normas más exigentes. Descubra nuestras certificaciones, nuestro enfoque de la garantía y el control de calidad, y la documentación que puede solicitar.

Trabajamos a su manera

Tanto si quiere crear un prototipo único como si prefiere hacer una producción de bajo volumen, tenemos el servicio que se adapata a su necesidad. Desde proyectos complejos desarrollados junto con nuestro equipo hasta una pieza que puede imprimir en línea cuando lo requiera; estamos aquí para ayudarle de la forma que más le convenga.

Pasión por la impresión 3D

Nadie apreciará tanto su proyecto como usted, pero nosotros estaremos muy cerca. La impresión 3D es nuestra pasión, por lo que nos dedicamos de lleno en cada paso y prestamos mucha atención a cada detalle. Combinamos nuestra experiencia y posición global con el apoyo local para que se sienta como en casa cada vez que trabaje con nosotros.

Compartimos el conocimiento

Creemos que el conocimiento debe compartirse. Nuestro equipo se centra en conseguir soluciones, lo que le permitirá acceder a todo lo que hemos aprendido sobre la impresión 3D en los últimos treinta años para garantizar el mejor resultado para su proyecto.

Sectores en los que trabajamos

Avance hacia el futuro del sector aeroespacial con plazos de entrega más cortos, tiradas cortas más asequibles y la inigualable libertad de diseño que ofrece la fabricación aditiva.

Desde prototipos y modelos visuales rápidos y eficaces hasta la fabricación de series de bajo volumen y herramientas para la automoción, abarque todos estos aspectos al incorporar la impresión 3D industrial en los flujos de trabajo de producción ya existentes o nuevos.

Entre en una nueva era de fabricación más sostenible y a la carta, en la que la creatividad y la innovación no tienen límites y en la que la rapidez de comercialización y el riesgo cero en las existencias impulsan la agilidad empresarial.

Independientemente de las tecnologías o máquinas, el software de Materialise gestiona y optimiza cada paso del proceso de producción, desde el pedido hasta la entrega.

Cree soluciones realmente únicas, permita la personalización masiva en toda su línea de productos, pase del diseño a la producción en serie de forma rápida y asequible, y benefíciese de cadenas de suministro sostenibles y sin riesgos.

Cree herramientas de producción y prototipos innovadores, optimice el tiempo de funcionamiento y haga que la obsolescencia quede obsoleta con piezas de recambio impresas en 3D que nunca dejarán de ser útiles y que se imprimen bajo demanda.

Tecnologías

En Materialise creemos que todos los diseñadores deberían poder crear productos sin limitaciones. Nuestra capacidad de impresión 3D, que comprende la gama más completa del mundo de tecnologías, materiales y grados de acabado, le ofrece un acceso realmente imparcial a la mejor solución para su proyecto.