Consultancy

Materialise Mindware

Helping you strategize and implement your AM ambitions

When you need guidance harnessing the power of additive manufacturing (AM), nothing beats first-hand experience. Our Mindware consultants apply 30+ years of proven AM knowledge and expertise to tackle your most pressing challenges with you, wherever you are in your AM journey. Let’s get started — your competitive edge begins here.

Tap into our AM expertise

Bespoke support

No one understands your business like you do, and no one understands 3D printing like we do. We’ll meet you exactly where you are in your AM journey to create a tailored program that suits your ambitions, needs, and timeline.

Proven experience

As industry pioneers, we’ve developed AM production lines for flying parts, patient-specific devices, and more. We live and breathe 3D printing, so we can quickly see where you are in your adoption journey and guide you to success.

State-of-the-art manufacturing

Gain access to advanced 3D printing facilities — our multiple sites and competence centers have 180 machines that offer nearly endless combinations of materials and finishes.

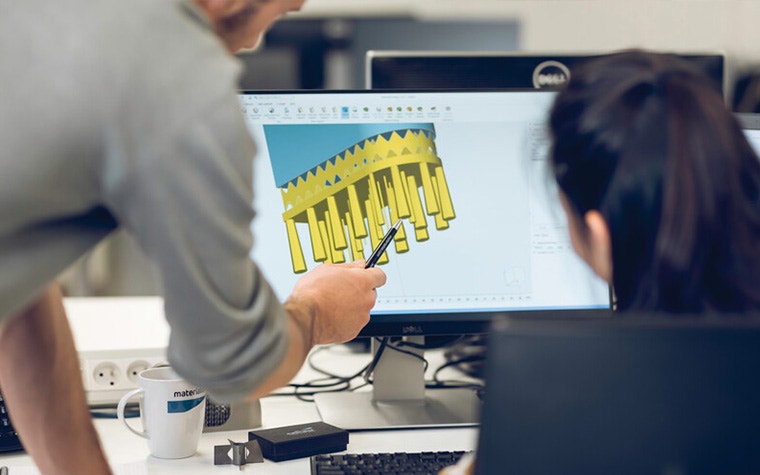

Advanced AM software

With our Magics and CO-AM software platforms, you have a complete suite of software tools for optimizing every stage of production, including application-specific software configurations designed especially for you.

Multidisciplinary teams

We bring together the profiles you need, when you need them, including experts in software, design and engineering, materials and technology, and R&D.

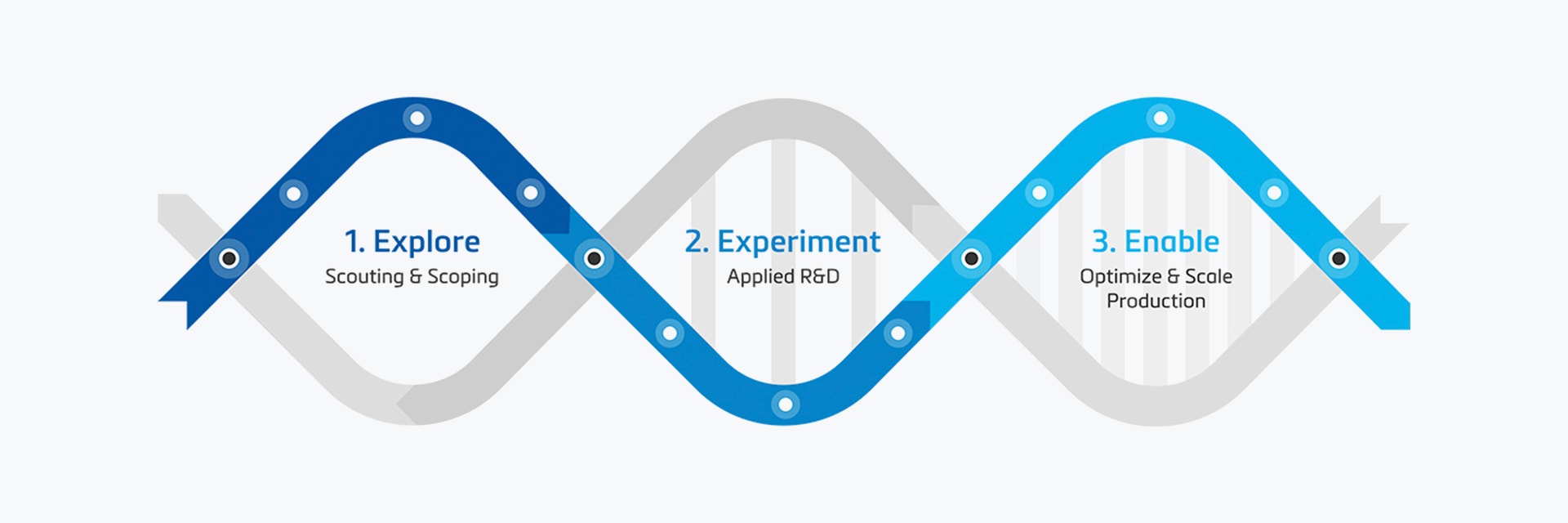

A unique offering tailored to you

Need help identifying your next steps with AM? We’ve got you covered. Whether you’re just exploring AM for your business, experimenting with application research, or enabling volume production by scaling up, we’ll build a bespoke program and provide proper training that suits your organization and budget.

Kickstart your AM adoption

Even when you’re convinced of AM’s value, there are hurdles every company needs to overcome — persuading stakeholders and finding optimal applications, for example. Our Explore programs help you translate business challenges into tangible AM opportunities. They include an AM Foundations Session, AM Strategy Roadmap Development, and an AM Application Scan and Assessment.

Research and develop applications

Once you’ve committed to an AM strategy, it’s time to make it happen. Our Experiment solutions are all about collaborative, hands-on research and development to validate your business case and ensure your investment is a success. The programs include a Technology and Materials Feasibility Assessment, Design and Engineering for AM, and Rapid Prototyping and Proof of Concept Validation.

Scale AM adoption

You’re no stranger to the benefits of AM, and you’re ready to take it to the next level. Together, we’ll fine-tune your production to ensure the repeatability and reliability you need with the help of programs like AM Process Optimization, AM Workflow Automation, and AM Factory — Digital Set-Up.

Mindware Connect: Experts on hand

Sometimes, a one-to-one conversation with an expert is all you need. Maybe you need to pinpoint exactly how to get started with AM or want to solve a specific problem. Mindware Connect is your opportunity to link up with our experts on a flexible basis. First, we set up an intake call to align on your goals. Then, we’ll create a tailored Connect package, whether that’s providing solutions to your challenges, offering advice, or acting as a sounding board.

Guiding innovation with unrivaled expertise

Impartial advice

We hold a technology-neutral position, so we identify the state-of-the-art techniques that best fit your needs, not the other way around.

A solid track record

We’ve helped companies in many industries make a difference with AM throughout our 30+ years. Our extensive journey will give you a head start on yours.

Result-oriented implementation

Putting strategies and plans into practice requires hands-on support. We dive right in with you, providing the proper tools, know-how, processes, and people.

Meet some of our AM specialists

Hanne Gielis

Alberto Cajiao

Lieze Chau

Wouter Maleux

Roman Plaghki

Dries Vandecruys

Toon Roels

Tom Cluckers

Nils Faber

Erik de Zeeuw

Giovanni Vleminckx

Jurgen Roekens

Frequently asked questions

Inspiration

Discover how other businesses are benefitting from working with our Mindware consultants.