CUSTOMER STORY

How Automation Helped FEops Accelerate Structural Heart Planning

The FEops team are long-term users of the Mimics Innovation Suite software. Co-founder and CTO Peter Mortier explained to us how it helped automate their clinical workflow. Doing so helped them to discover how automation benefits structural heart planning.

Since its foundation in 2009, FEops has grown from a small academic spin-off to an internationally recognized team of almost 40. Its latest CE-marked structural heart planning service, FEops HEARTguide, is available in markets such as the EU, UK, Canada, and Australia. Such growth does not happen by accident. For CTO Peter Mortier and his team, it represents more than ten years of hard work. During which time they successfully shifted their focus from consultancy to development.

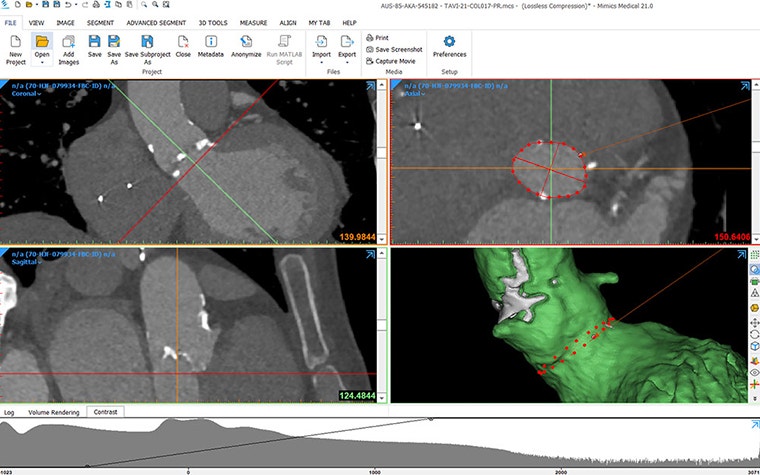

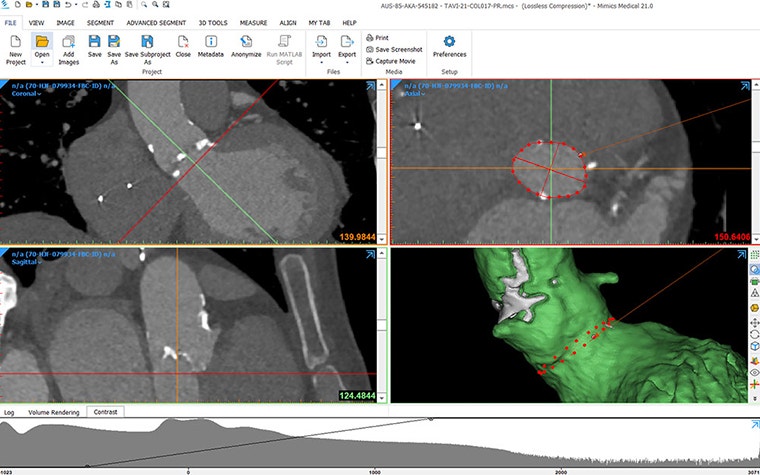

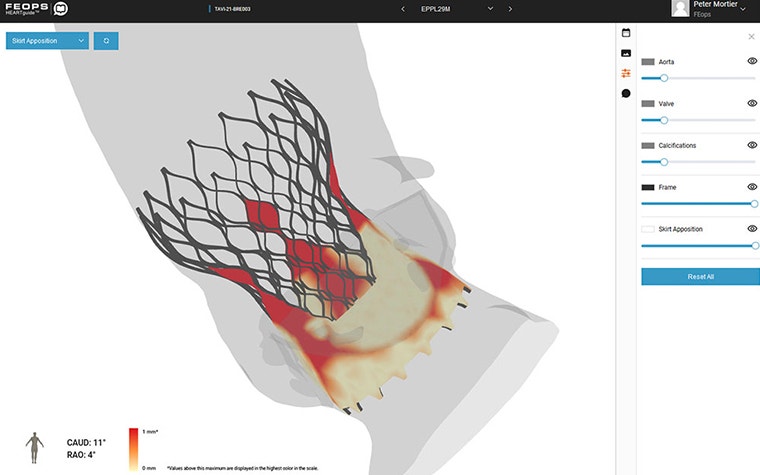

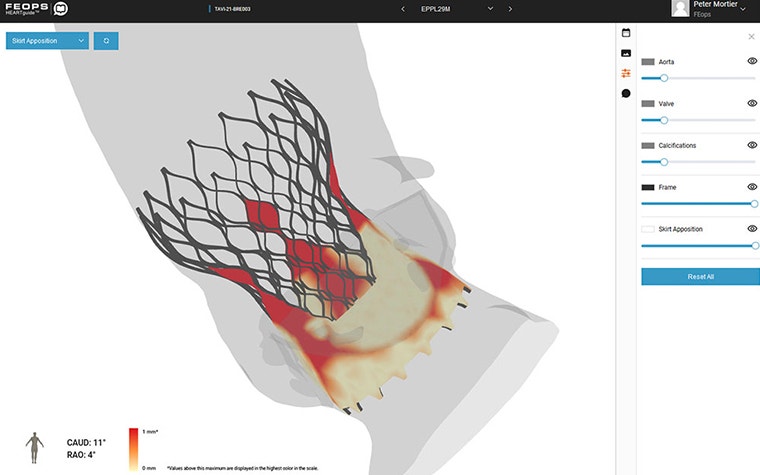

For physicians, this service provides valuable insights before they even set foot in the operating room. Using Mimics Innovation Suite (MIS), the team builds a 3D reconstruction of a patient’s anatomy from a CT scan, takes the necessary anatomical measurements, then performs a virtual intervention using computational modeling.

The Power of Mimics Innovation Suite

Within these models, the team can implant a device into a 3D reconstruction of each patient. They use this to predict how that implant - and the anatomy itself - will deform, along with certain complications. For many years, the FEops team has used MIS to build the 3D reconstruction, perform anatomical measurements with landmark identification, and take screenshots of the anatomy. The cardiovascular module is also appreciated, particularly for its ability to segment the different regions of the heart.

Understandably, time is of the essence with these procedures – and it’s a demand that FEops is proud to meet. The output is delivered to the physician within one working day for a left atrial appendage occlusion (LAAO) or two working days for a transcatheter aortic ventricular implantation (TAVI). Better yet, it’s a key performance indicator (KPI) that the team achieves in more than 90% of the cases.

Increasing Workflow Efficiency Through Automation

For Peter and his team, automating as much of the process as possible is key to hitting these KPIs. This is already the case for most of the initial setup and post-processing tasks. But the goal, as it has always been, is to improve even further. Developing in-house artificial intelligence (AI) models has helped them do that, though the process is still ongoing. The recent launch of the MIS Scripting Module came at the perfect time, with FEops seeing it as an ideal addition to their new AI approach.

Peter says, “We could start using these AI models, but the next challenge was learning how to check and correct the AI output where needed. That’s when we started looking into the Mimics Scripting Module because that could be the interface between the output from our AI models and still allow our case analysts to make some modifications. Mimics Scripting was the perfect tool for that. We could import masks or landmarks, and then this can be inspected and modified if needed.”

Though this combination is still relatively new, FEops is already benefitting from some promising results - particularly in reducing the learning curve for new additions to the team. Used together, the in-house developed AI models and Mimics Scripting Module have created a time saving of around 20% for new case analysts since May 2021. They’re optimistic that further improvements will be seen in the future. Great news for a company seeing significant growth and an ever-increasing caseload.

The Future of Preoperative Planning

This increase in volume proved the main driver behind the adoption of automation, with the desire to improve scalability and reduce the costs of service a key consideration. By reducing the amount of manual work involved, Peter hopes this new process will lead to an exciting future for preoperative planning.

“Using our AI in combination with scripting, we can reduce the variability between case analysts. But mainly, it's to reduce the cost and the turnaround time even more than we have today. Twenty-four hours is already a very nice lead time, but sometimes we still feel that if we could be faster — if it was 12 hours, for example — we could serve the hospitals that do their CT the day before the intervention as well.”

The ultimate goal is to reach a point where physicians can self-operate the FEops software to receive results in real-time, but this is very ambitious. After all, fully automating an entire workflow when relying on CT images with a wide range in quality is a big challenge.

An intermediate step is one in which only quality control remains as a manual process, with 90% of cases going straight ahead. It’s certainly within the realms of possibility. FEops has reduced the time needed for each TAVI simulation from over twenty-four hours to around 90 minutes in only seven years.

In the near future, automation is likely to have a major role in the field of structural heart planning. With some hospitals providing over 500 TAVI cases each year, it will become necessary to handle the time-consuming analysis of each patient’s anatomy. For more complicated procedures, like those which require an analysis of multiple phases of a cardiac cycle, this process is even longer, creating a potential bottleneck for physicians.

Luckily, they need to look no further than FEops to see the benefits adopting automation can bring - to both a clinical workflow and the patients they care for.

L-102276

Partageons :

Vous aimerez peut-être aussi

Ne ratez jamais une histoire comme celle-ci. Recevez-les dans votre boîte de réception une fois par mois.