DIRECTRICES DE DISEÑO

Silver

Wall thickness

In 3D printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. For most models in Silver, the minimum wall thickness you can use is 0.6 mm for the gloss finish and 0.8 mm for the high gloss finish. However, when making something small such as the band of a ring, the wall thickness should be at least 1 mm. The fragility of the silver might cause the ring to break when you wear it if the model is too thin.

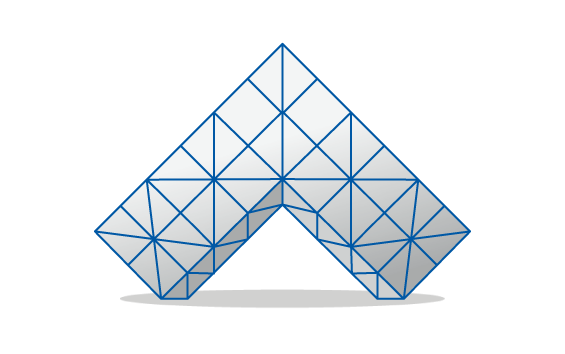

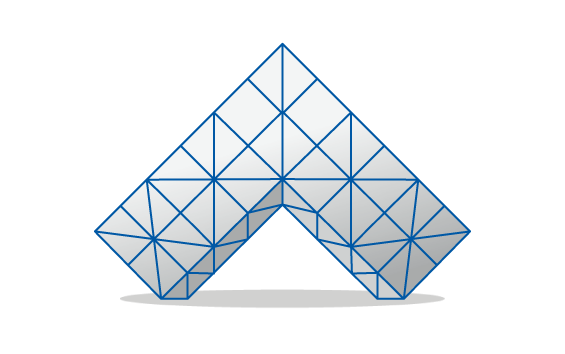

High definition

Since the resolution of the wax printing process is so high, make sure that you create your model and export your file with enough definition so you don’t see the triangles.

Geometry

Be careful when having large areas of your model connected or supported by thin rods. Compare it to a big head resting on a thin neck. Your model needs to be designed to adequately support itself, so make sure the rods are strong enough to ‘carry’ the weight of the larger area. Also, it is possible to print internal structures, but removing support structures, cleaning them and casting them can be difficult or even impossible. If you have doubts about whether your model is feasible, please contact us.

Hollowing

This material allows you to print hollow models. However, keep in mind that you need to incorporate multiple holes or slots so that we can get rid of any unprinted wax resin. Make as many holes or slots as you possibly can. We recommend making two or more holes or slots. Make sure the holes are spread out equally; for example on opposite ends of your design. The holes should have a diameter larger than 1.5 mm. In addition, you will need to make sure that the casting plaster is sufficiently supported or your model will not be able to be cast properly.

Feature size

The smallest features in your design should be at least 0.35 mm in diameter and 0.4 mm in height and attached to a solid surface. Details this small are suitable for delicate projects such as micro pavé settings.

Because Silver is not a very strong material, longer features such as rods or prongs (in mesh-like structures) should be at least 0.8 mm in diameter. Otherwise, they might break during casting or even when you wear the piece.

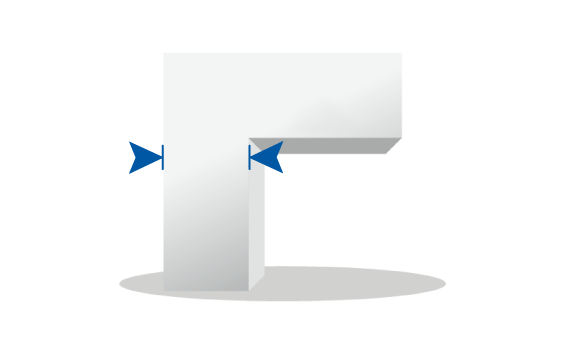

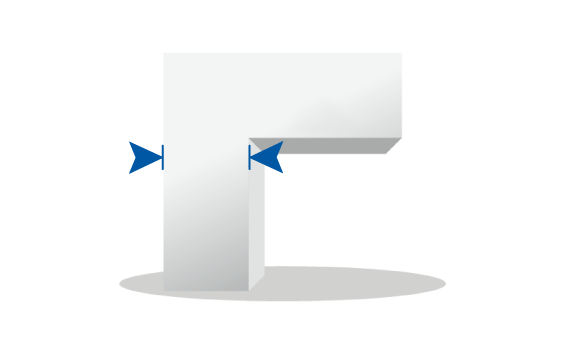

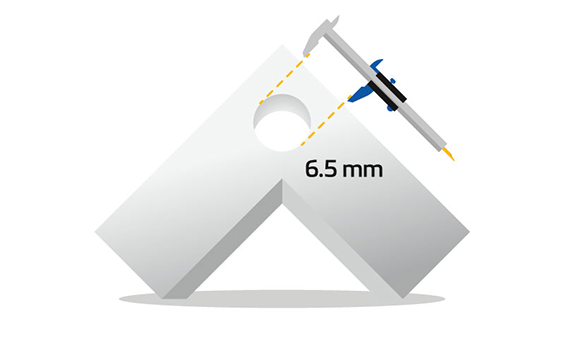

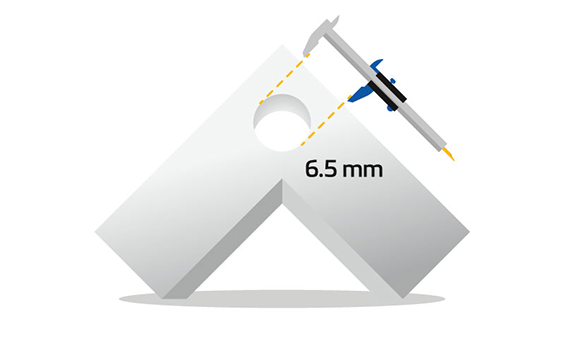

Clearance

The distance or space between two or more parts in your model is called clearance. If there is too little clearance between the parts, they might become fused during the casting of your model. Your model is first printed in wax, placed in a container, and covered in a liquid plaster. Then the wax is burned out, creating a cavity in the now-hardened plaster, leaving a plaster mold ready for casting.

If the gap between the different parts in your model is too small, the plaster may not fully flow in or may create overly-thin walls in the mold that break when liquid metal is poured in. Both of these will result in defects in your casted model. Therefore, we advise a minimum gap of 0.3 mm. If it is impossible to increase the gap in your design, you can consider fusing the features if their separation is unnecessary.

Polishing

In order to polish, we have to be able to reach the surfaces. As a rule, we can't file, sand or polish cavities, and small sharp edges will be rounded off. Also, complex internal, mesh-like structures are impossible to reach.

Influence of finishes on level of detail

Once your model is cast, it will go to finishing. The post-processing techniques for gloss, satin, sandblasted and high gloss silver are all unique and each will have a different effect on your model’s level of detail.

- Polished: Models are post-processed in a magnetic tumbler. This technique is the least aggressive process for silver and will erode your model by about 0.05 mm to 0.075 mm. This finish is best suited to maintain a high level of detail; however, surfaces will be left uneven and not as smooth as high-gloss models.

- Corundum blasted (Matte): Models are post-treated with an abrasive blasting operation. The surfaces of your model will get a smooth, matt look. This finish will erode your model by about 0.10 to 0.15 mm.

- Brushed: Models are manually post-treated with a wire brush. This finish will eat away 0.10 to 0.15 mm of material from your model.

- Hand polished: Models will undergo a manual mechanical polish. The polishing technique is the most aggressive and will erode your model by about 0.10 to 0.15 mm. Sharp corners will be rounded. Therefore, this technique will result in the lowest level of detail for Silver but provides the highest level of smoothness and shine.

- Polished + Black patina: Models undergo a manual mechanical polish. This polishing technique is the most aggressive; it will erode your model’s outer surfaces by approximately 0.10 to 0.15mm and will round sharp corners. Therefore, this technique results in the lowest level of detail for silver but provides the highest level of smoothness and shine.

It’s good to take the amount of erosion from these finishes into account when you are designing your model.

Nested objects, hinged and interlocking parts

Nested objects (objects floating within another object), hinged parts, and interlocking parts, such as chains, cannot be made with lost wax casting. The reason is that support structures have to be removed before being cast in Silver.

Embossed and engraved details

For embossing or engraving details such as text, we advise you to keep a maximum height/depth-to-width ratio of 1:1. Also, keep in mind the minimum wall thickness of 0.35 mm.

Antique models: Dimensions

Antique models — with a Polished + Black patina finish — are finished in two steps. First, your model undergoes an oxidation process in which a sulfur mixture causes the silver to become duller and darker. Then, the elevated surfaces of your model are polished manually. Recessed or sunken areas are left untouched and therefore stay darker than the elevated, polished areas.

Minimal dimensions of sunken 'darker' areas: Sunken areas need to have a minimum area of 0.4 mm long x 0.4 mm wide x 0.4 mm high to give visible results. Because the final polishing is a manual process, each model will be unique.

File requirements

We accept file formats STL, 3DS, 3DM, OBJ, WRL, MATPART, STP, SKP, SLDPRT, STEP, CATPART, IGES, MODEL, MXP, and MGX on Materialise OnSite.

As well as the need to respect these file formats, there are also constraints related to the content of those files. To deliver the best possible quality and ensure traceability, we only allow one model per part to be ordered via our online platform OnSite.

This means per file, there can only be one shell. If there are multiple shells in one file, we will only process it as it is recognized as one model or part meaning that the shells are intersecting or interlocking each other (if applicable see the technical specifications below). Otherwise your part will not be processed correctly.

Especificaciones técnicas

| Dimensiones máximas de la pieza | 88 x 88 x 125 mm |

| Precisión estándar | ±5 % (con un límite inferior de ±0,35 mm) |

| Grosor de capa | 0,016 mm |

| Grosor de pared mínimo | 0,6 mm |

| Tamaño mínimo de detalle | 0,35 mm |

| Piezas de enlace o móviles | No |

| Canales internos | No |

| Estructura exterior | Superficie rugosa y ligeramente brillante |