DIRECTRICES DE DISEÑO

PA 12 (SLS)

Wall thickness

In 3D printing, wall thickness refers to the distance between one surface of your part and the opposite sheer surface. For PA 12, we recommend a minimum wall thickness of 1 mm but living hinges are possible at 0.3 mm. High wall thickness can give you a strong solid surface, while lower wall thickness can create a flexible and expandable surface. For example, thin surface walls are ideal when designing a spring that needs some suspension properties. This makes your part light and flexible. The opposite effect can be achieved by making your surface walls thicker.

Hollowing

If possible, try to hollow out your part. This avoids deformation and discoloration during the printing process. You can either hollow out your part without a surface hole, which means that unsintered powder will remain trapped inside, or you can design a strategically placed hole (two would be even better) so that the unsintered powder can be easily removed after printing. If the part needs to be reclosed, design a lid with a diameter allowing for 0.5 mm play between the part and the lid.

If your part has walls thicker than 9 mm, our production team may hollow out the part to prevent deformation and discoloration. For parts with wall thickness higher than 20 mm wall thickness, this is done by default. In that case, the powder will stay trapped inside.

Warpage and deformities

We strongly recommend that you do not design large, flat plains in dimensions like an A4 page. In most cases, your model will deform. This process is called “warping”. Creating support ribs under your plane does not solve the problem, but rather increases the chance of deformation even more. The key here is to avoid large flat planes.

Interlocking parts

It is possible to print interlocking and moving parts or single-build assemblies in PA 12 (SLS). Parts that are printed together should have a minimum clearance of 0.5 – 0.6 mm. If you want to print a chain, spacing between your surfaces is crucial. The more space you can afford the better. The more complex your part is, the more difficult it becomes for us to evacuate unsintered powder from the interior when the part is taken out of the 3D printer. Please get in touch with our team before ordering parts of this kind to ensure printability and avoid disappointments.

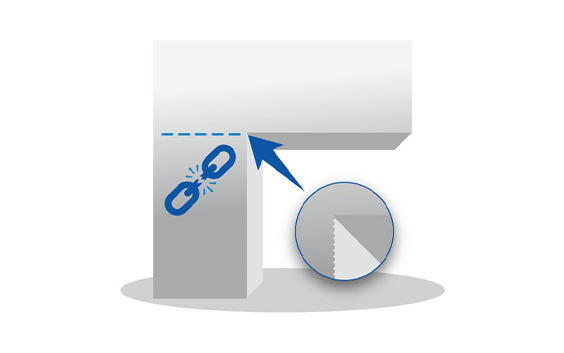

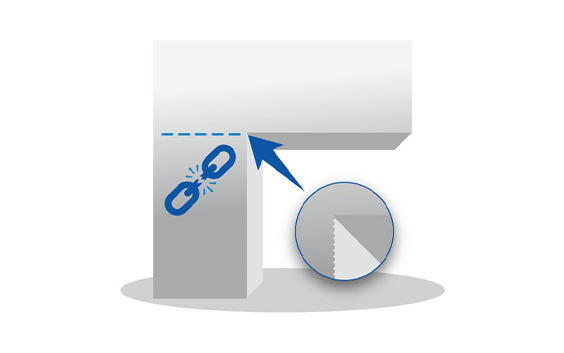

Assembly

When designing parts that need to be assembled, it’s important to maintain enough distance between the parts. A perfect fit in your CAD software does not necessarily ensure a perfect fit after printing because your software ignores the friction present in the real world. Therefore, always leave at least 0.6 mm between the different parts. For parts with large surfaces and wall thicknesses, you will need to maintain even more distance between the parts. In cases like these, please get in touch with our team to check printability.

In order to help us print your parts with the best possible dimensions for assembly, please design your files with an orientation equal to the relative orientation of your parts in the final assembly.

Embossed and engraved details

For engraved text or surface details, we recommend letters with a minimum line thickness of 1 mm, a depth of 1.5 mm, and an overall height of at least 4.5 mm. Embossed text or surface details should be thick enough that they will not break during production or transport. We recommend letters that have a line thickness of at least 0.8 mm, an overall height of at least 3 mm, and a depth of at least 0.8 mm.

Holes and channels

Holes with a small diameter are exposed to a lot of heat during the sintering process. This can cause the powder inside the holes to become fused. To make sure that holes in your parts remain clear, design a diameter of at least 1 mm.

Longer internal channels can be difficult to clear out, especially if the powder is partially sintered together. We recommend a diameter of at least 3 mm for internal channels. In the case of complex channel geometries with several turns, please get in touch with our team to check printability.

Smoothing: Strength and fragility

Several factors make it hard to fully predict the outcome of the polishing process. One of them is the geometry of your part, which can act differently each time it is put in the tumbler. In general, you should have wall thicknesses of at least 1 mm throughout your part.

Although we carefully place and orientate your parts in our printers to minimize 'weak points' created by the layered buildup of your part, certain elements of your design may be more sensitive to the impacts of the polishing stones than others. Therefore, we suggest adding some extra wall thickness if your design can allow for it. Smoothing is not advised if your part has tiny details like pins because they are likely to break off during the polishing process.

The largest dimension of your part should not be more than 200 mm, as bigger parts can get stuck during the smoothing process. The smallest dimension should not be less than 30 mm, as smaller parts can break in the process.

Smoothing: Interior polishing

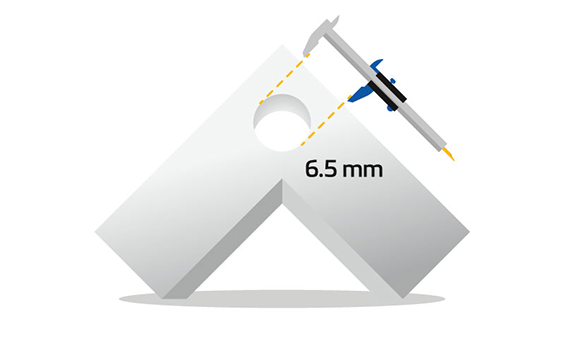

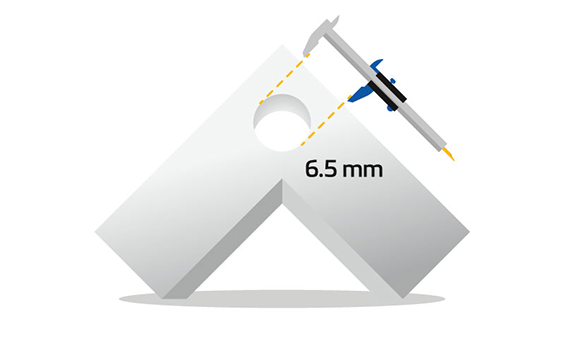

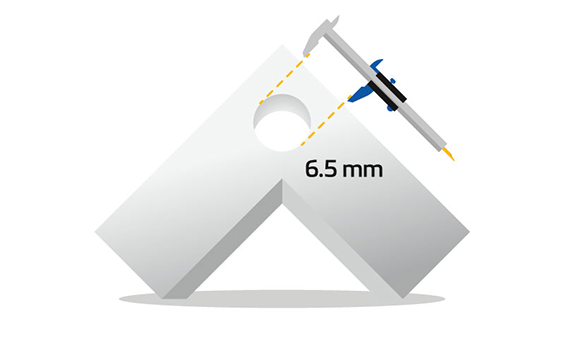

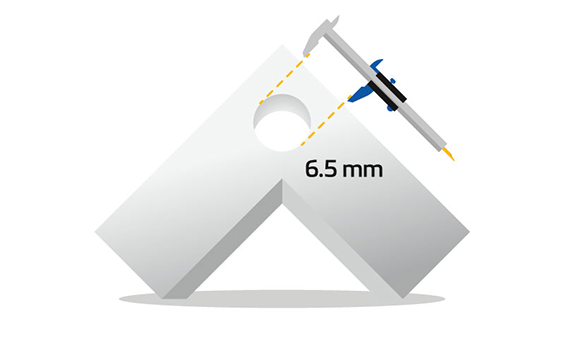

The small size of the polishing stones means that they can easily get stuck inside small holes. Therefore, we recommend that any openings which need polishing should be larger than 6.5 mm in diameter. This helps prevent stones from getting stuck inside your model.

Also, note that the inside of your model will always be less polished than the outside. In fact, your part will not be polished at all on the inside if the holes are smaller than 6.5 mm because the stones will not be able to enter.

Smoothing: Rounded edges

If your part contains sharp edges, these will be rounded off. Rounded corners and smooth transitions between surfaces will have a higher degree of polishing than sharp edges.

Smoothing: Embossed and engraved details

Embossed details on your model tend to be worn away by the polishing stones. Make sure to raise these details by at least 1 mm, otherwise they may disappear when your model is polished. Engraved details are less of a problem because, in most cases, the stones won’t be able to reach the inside of the engraving; however, the edges may still be affected. To be on the safe side, make sure your engravings are deeper than 1 mm.

Sealing: Accessibility

Due to the process described above, surfaces which cannot be accessed easily will most likely be treated less, leading to a lower level of sealing. For internal channels, make sure that the diameter is above 6 mm or the channels could get blocked with sealing agent.

Sealing: Watertightness

Please be aware that the sealing agent improves how watertight your design is but does not guarantee a fully watertight product as this depends on several factors, including the complexity of your design, the temperature of your surroundings, the pressure used, the liquid used etc. We recommend this finish for decorative use and advise testing your application first before fully using it.

File requirements

We accept file formats STL, 3DS, 3DM, OBJ, WRL, MATPART, STP, SKP, SLDPRT, STEP, CATPART, IGES, MODEL, MXP, and MGX on Materialise OnSite.

As well as the need to respect these file formats, there are also constraints related to the content of those files. To deliver the best possible quality and ensure traceability, we only allow one model per part to be ordered via our online platform OnSite.

This means per file, there can only be one shell. If there are multiple shells in one file, we will only process it as it is recognized as one model or part meaning that the shells are intersecting or interlocking each other (if applicable see the technical specifications below). Otherwise your part will not be processed correctly.

Especificaciones técnicas

| Dimensiones máximas de la pieza | 630 x 330 x 550 mm 270 x 270 x 270 mm (pedidos de servicio rápido) |

| Precisión estándar | ±0,3 % (con un límite inferior de ±0,3 mm) |

| Grosor de capa | 0,12 mm |

| Grosor de pared mínimo | 1 mm |

| Tamaño mínimo de detalle | 0,3 mm |

| Piezas de enlace o móviles | Sí |

| Canales internos | Sí |

| Estructura exterior | Estructura granulosa |