CASE STUDY

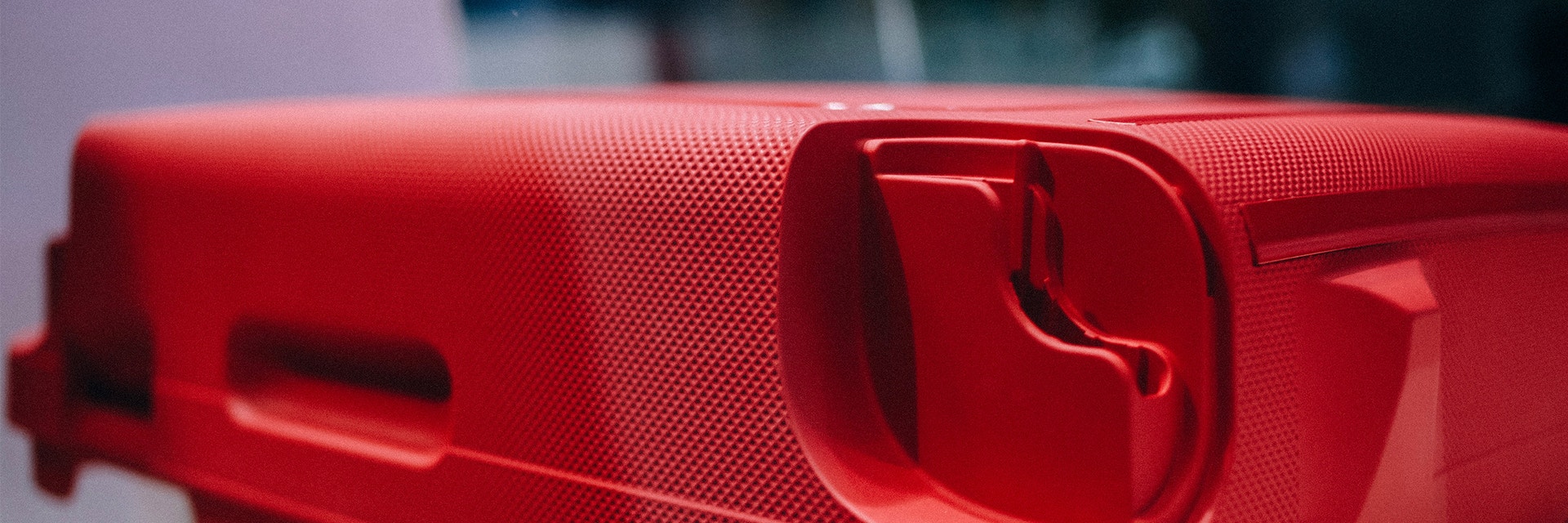

10 Years of 3D Printing at Samsonite: Innovation from Design to the Production Line

From concept to mass production, innovation is wired into Samsonite’s manufacturing DNA. Every year, the design team at Samsonite Europe in Oudenaarde, Belgium, creates several fresh collections of hard-shell suitcases for the European market. Some are facelifts, some are completely new collections with all-new functional components. All of them go through a rigorous process of design reviews and functional testing before making it onto the production line in one of Samsonite’s three European facilities in Belgium and Hungary. Over the last ten years, 3D printing has helped the design team find original solutions to complex challenges as they move new projects forward.

業界

Consumer Goods

ソリューション

Laser sintering

PA 12

アプローチ

Improved production efficiency

Design freedoms

Reduced tooling costs

Product innovation

“3D printing helps us get the right design on the market fast — while meeting the high standards our customers expect from the brand,” explains Vivien Cheng, Head of Product Development at Samsonite Europe. “Every single one of our cases has to be lightweight as well as super-strong; durable as well as user-friendly. Initially, we used 3D printing mainly for visual, then functional, prototypes. Today, we use the technology at every stage of the process: for visual prototypes, proofs of concept, functional prototypes, and production line tools.”

Despite the high volume of 3D-printed parts now required by Samsonite on a weekly basis, the company has made a strategic decision to rely on external suppliers like Materialise rather than setting up its own 3D printing production facility — a decision driven by cost-benefits, flexibility, continued access to leading-edge technology, and fruitful creative partnerships with 3DP domain experts.

Preventing unnecessary costs with prototyping

Most of the components used in Samsonite’s hard-shell cases are injection-molded. Making the real part, therefore, comes with a significant price tag. The mission for the design and engineering teams: avoid having to do expensive mold modification or even ordering molds in vain.

“Spending a large amount of budget on prototypes might seem like a big investment,” continues Vivien, “but if it helps us make each part perfect before we order molds worth hundreds of thousands of euros, then that is money very well spent. 3D printing allows us to go through fast cycles of iteration and thoroughly test and assess each variation in between. We can quickly answer key questions like ‘Is this new type of handle comfortable? Does it look good? Will it break?’ and ultimately ‘Does this new concept do what the user needs it to do on a practical, functional level?’. New technical concepts can involve highly complex shells with new functionality — internal compartments, for example, that turn the suitcase into a mobile office. Being able to see these ideas and concepts in real life before we commit to a specific design is incredibly important. Sometimes, we have a large part of the suitcase printed for design verification and product optimization, so that we could make sound decisions faster.”

Functional prototypes are used for product quality testing. Shell reinforcement parts can be printed specifically for drop test evaluation, and depending on the QA results, reinforcement parts can be further optimized before we confirm the order of expensive injection molds. In this way, Samsonite can mitigate the risk of product failure before the final product is produced.

Visual 3D-printed prototypes can be useful for marketing purposes, too, allowing the team to show concepts long before they go into production, with the same cosmetic attributes as the final product. The ability to print textures, a unique benefit of 3D printing, and replicate the appearance of different materials ensures the team can create a visual twin of the final product.

A gripping tale: 3D-printed production line tools

Beyond prototyping, Samsonite has also been using 3D printing for real, functional parts: tools on its production lines in Belgium and Hungary.

As of 2011, Samsonite has used 3D printing technology to facilitate its laser cutting operation in production. To prevent smoke generated by the laser from staining suitcase shells, Samsonite 3D printed jigs to act as a mask. This “mask” consists of 2 components: the carrier is printed in PA 12, and the sleeve is printed in Duraform Flex. Making such 3D-printed jigs offered a simple and fast way to facilitate production, and today, 50 to 60 such jigs are in operation on the production lines at Samsonite.

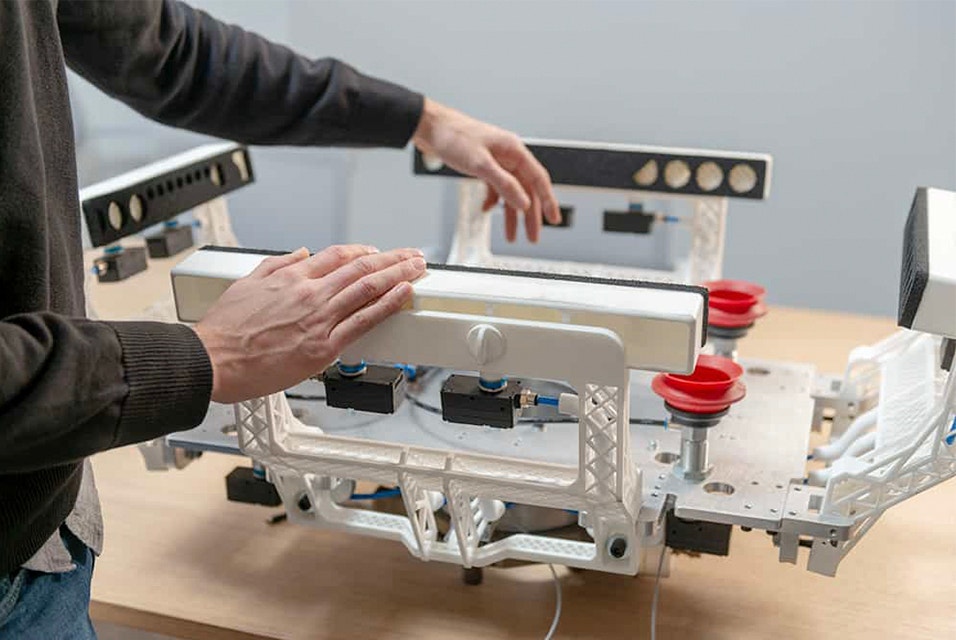

Other tools created additively — whether to be lighter, more ergonomic-by-design, or to add specific functionality — include various grippers for robots to carry out picking tasks and a wide range of jigs that can be more easily mounted on shells for the countless gluing, placing, and cutting tasks involved in making a hard-shell suitcase. 3D-printed parts are also used as control and calibration tools to carry out checks on the line.

““Another area where the benefits of 3D-printed parts really kick in is weight. With traditional methods of making the grippers for these, we're constantly at the weight limit. With 3D printing, we're nowhere near it, giving us room to add extra functionality to the grippers.””

— Nicolas De Vogelaere, Mechanical Engineer Tooling

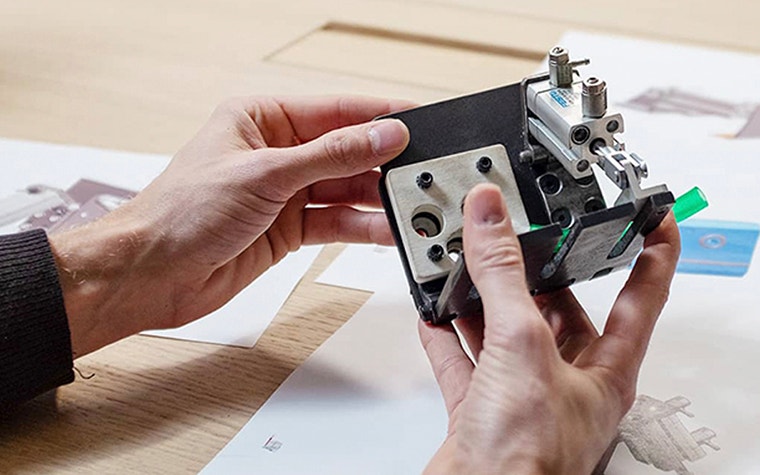

“We use a lot of pneumatics, in grippers, for example,” explains Nicolas De Vogelaere, Mechanical Engineer Tooling. “Functionality previously built into the part using plastic tubes can get damaged easily, which can then lead to downtime on the line. A major advantage of 3D printing is that we can design air channels directly into the part without separate tubing. It’s cheaper because you have no extra assembly time and it's more reliable.

“Another area where the benefits of 3D-printed parts really kick in is weight. This is not just about making it easier for our employees, who don’t have to lift as much. We’ve got robot arms that come with a maximum load, say 10 kg. With traditional methods of making the grippers for these, we’re constantly at the weight limit. With 3D printing, we’re nowhere near it, giving us room to add extra functionality to the grippers.”

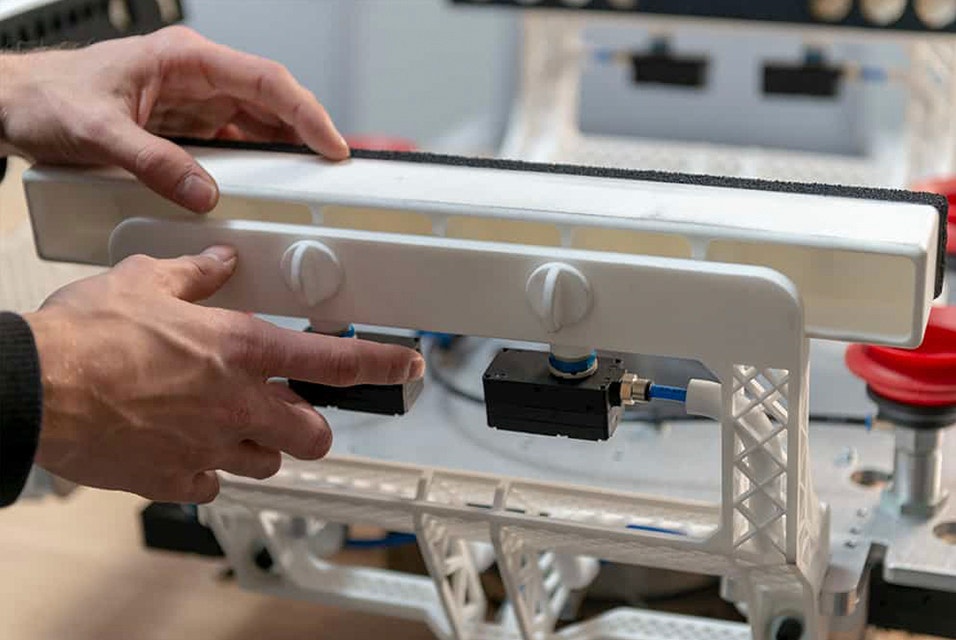

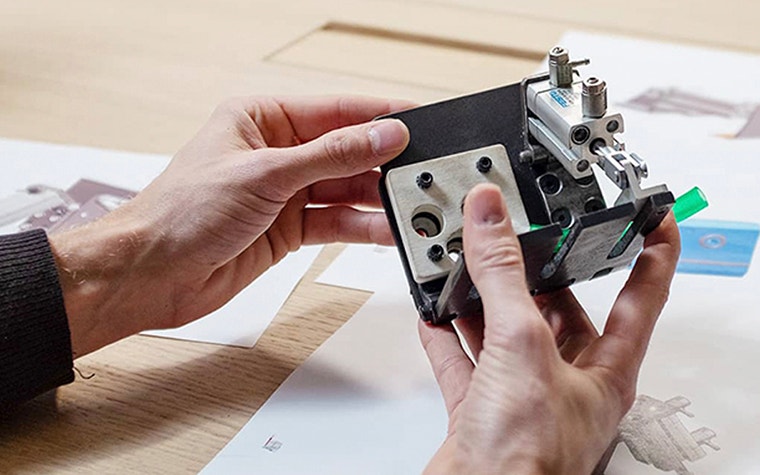

A live example of a gripper that has been reimagined with 3D printing is one created for the assembly of a new suitcase design.

The injection mold for the new carry handle has four cavities, producing two different pairs of pieces within every cycle. Normally, after each cycle, the four parts would fall onto a conveyor belt and then be sorted by an operator. From there, the sorted parts would be sent to the assembly line where they are put together and mounted on the suitcase.

The new gripper will be used to pick parts out of the mold and then click the corresponding pieces together straight away. This eliminates the sorting operation and skips a step-in assembly, thereby saving time.

“If we had to make the gripper with conventional methods and in full metal parts, it would weigh and cost significantly more than the 3D-printed part,” added Nicolas. “It is the first time that we have built something like this, and the benefits in terms of production efficiency and tooling costs are self-evident.”

Learning to design for AM

When Nicolas and his colleagues first started exploring 3D printing, they were able to draw on the experience already gained by the design and development team. However, applying additive technology to production tools meant designing real, functional parts that would have to work every day.

Working with Materialise, the Samsonite tooling team learned to think differently about how to approach the design of a part when making it additively, deepening their understanding of the benefits and design freedoms of 3D printing, but also of its specific design rules (taking into account layers, build orientation, etc.). For Nicolas, this has led to an even better relationship with the 3D printing provider.

“Most of the time now, when we send a design file to Materialise, they can send it straight to the machine for printing, whereas in the early days, they would have had to modify and improve them. It has become a very efficient process, one which also means Materialise can focus on helping us with more specific or unusual design challenges as and when the need arises.”

— Nicolas De Vogelaere, Mechanical Engineer Tooling

“We’ve developed a really thorough in-house understanding of the design possibilities at our disposal,” says Nicolas. “This way, we can reduce the number of parts in an assembly, add functionalities, and make parts that would have simply been impossible to create using traditional methods. Most of the time now, when we send a design file to Materialise, they can send it straight to the machine for printing, wherein in the early days, they would have had to modify and improve them. It has become a very efficient process, one which also means Materialise can focus on helping us with more specific or unusual design challenges as and when the need arises.”

Why not invest in an internal 3D printing facility

The efficiency of this process is hugely important. In an average week, the design, prototyping, and production line teams request between 100 and 150 digital parts for a pre-agreed, fast turn-around. But at such high volumes, why hasn’t Samsonite decided to take 3D printing in-house? For Vivien, the answer isn’t just about convenience; it’s about competitive advantage.

“Additive manufacturing is still evolving incredibly fast, and we want to retain access to the most cutting-edge processes and materials,” she explains. “We know Materialise is very much at the frontier of the 3D printing industry; they’re always updating their machine park capacity and adding or developing new processes and software. For all the varied uses where we deploy 3D printing, we want to be sure we are always using the best method, the best technology. If we had our own machines, in addition to the associated maintenance and operator cost, we would be limiting ourselves to the processes we’ve got in-house. That’s currently not an attractive option for us.

“Our products, the way we make them, and ultimately, our customers benefit most when we exploit the possibilities of 3D printing to the fullest. A partnership like the one we have with Materialise delivers just that. We’re plugged directly into the latest thinking, best practice, and newest innovations.”

以下で共有する: