LINEE GUIDA PER LA PROGETTAZIONE

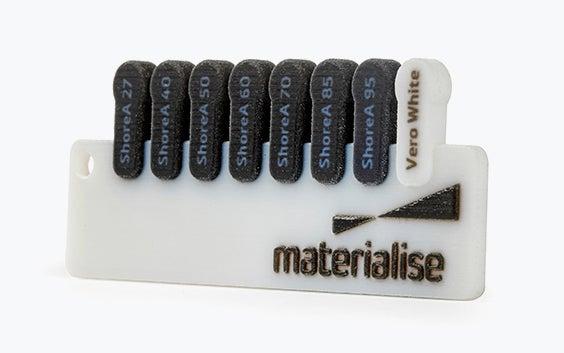

Composite materials

Wall thickness

In 3D printing, wall thickness refers to the distance between one surface of your part and the opposite sheer surface. For PolyJet, the minimum wall thickness you can use is 1 mm, which will provide you with a strong solid surface.

Dimensional accuracy

PolyJet technology is among the 3D printing processes (for plastics) with the highest dimensional accuracy. Dimensional accuracy does not relate to the detail of your part but to the deviation from the nominal size. The standard accuracy of PolyJet materials ranges between 0.1 – 0.3 mm (varying depending on geometry, part orientation and print size).

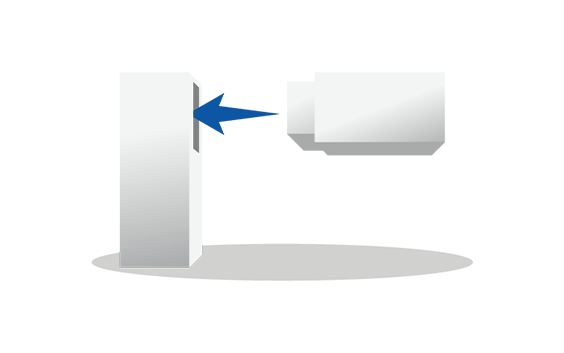

Interlocking or moving parts

It’s possible to print interlocking and moving parts (e.g. a ball bearing) in PolyJet because it uses water-soluble support material. Parts that are printed together should have a minimum clearance of 0.4 mm.

But please get in touch with our team before ordering these kind of parts to check printability.

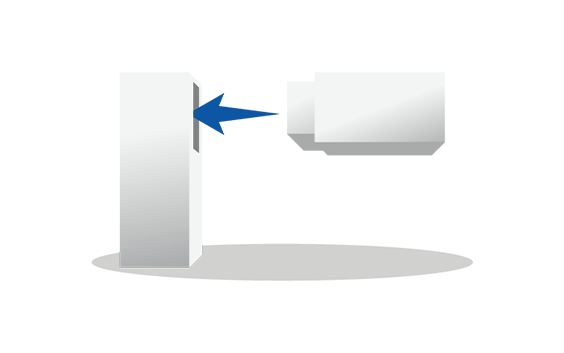

Assembly

When designing parts that need to be assembled, it’s important to provide enough distance between the parts that will be attached together. A perfect fit in your software package does not mean a perfect fit after printing because your software ignores the friction present in the real world. Therefore, always leave at least 0.6 mm between the different parts.

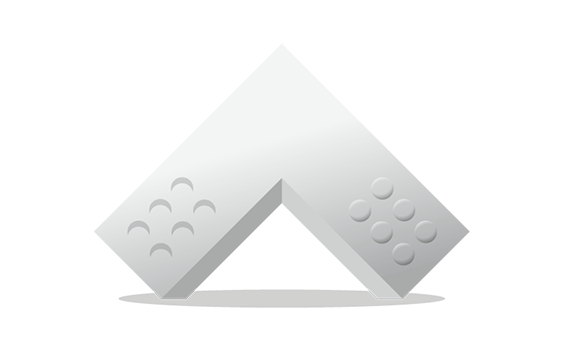

Embossed and engraved details

For engraved text or surface details, we recommend letters with a minimum line thickness of 0.5 mm and a depth of 0.5 mm. For embossed text and surface details, we recommend letters that have a line thickness of at least 0.8 - 1 mm and a depth of at least 0.5 mm.

File requirements

We accept file formats STL, 3DS, 3DM, OBJ, WRL, MATPART, STP, SKP, SLDPRT, STEP, CATPART, IGES, MODEL, MXP, and MGX on Materialise OnSite.

As well as the need to respect these file formats, there are also constraints related to the content of those files. To deliver the best possible quality and ensure traceability, we only allow one model per part to be ordered via our online platform OnSite.

This means per file, there can only be one shell. If there are multiple shells in one file, we will only process it as it is recognized as one model or part meaning that the shells are intersecting or interlocking each other (if applicable see the technical specifications below). Otherwise your part will not be processed correctly.

Specifiche tecniche

| Dimensioni massime del pezzo | 350 x 250 x 100 mm |

| Precisione standard | 0,1-0,3 mm (varia in base a geometria, orientamento del pezzo e dimensioni di stampa) |

| Spessore del layer di stampa | 0,032 mm |

| Spessore minimo della parete | 1 mm |

| Dimensione minima del dettaglio | 0,5 mm |

| Pezzi mobili o collegati | Sì |

| Canali interni | No |

| Struttura della superficie | Superficie leggermente ruvida e opaca |