CASE STUDY

3D Printing Meets Prehistoric Preservation: Materialise Prints Life-Size Mammoth Skeleton

Discovered near the Belgian city of Lier in 1860, the Lier mammoth had been displayed in the Royal Belgian Institute of Natural Sciences (RBINS) in Brussels since 1869. With the re-opening of Lier’s City Museum just months away, the local Kiwanis community approached Materialise with an exciting idea: use 3D printing to create an exact, life-size replica of the skeleton for Lier’s own museum.

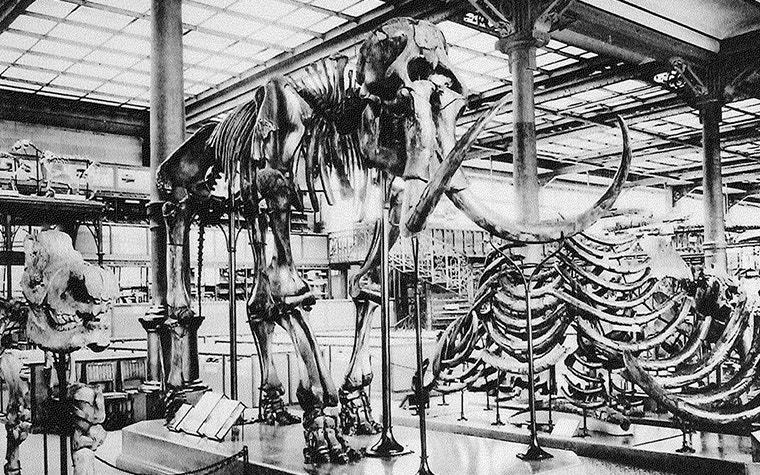

Founded in 1846, the Royal Belgian Institute of Natural Sciences (RBINS) in Brussels is home to over 250 research scientists, 38 million specimens and, since 1869, the Lier mammoth — the first skeleton of its kind ever to be displayed to the public in Western Europe.

Discovered, as its name suggests, in the municipality of Lier in Antwerp, the skeleton is still one of only a few full mammoth skeletons in existence. This rarity makes it of vital scientific importance, not to mention a thrilling exhibit for natural history enthusiasts the world over. With this in mind, the re-opening of the City Museum of Lier presented an exciting opportunity. The original bones couldn’t be moved from Brussels, but they could be recreated.

The challenge

Recreate a life-size replica of a mammoth skeleton

The design freedom and precision possible with 3D printing made the technology an obvious choice for recreating the mammoth of Lier, which counted over 300 individual bones. As Dr. Mietje Germonpré, Paleontologist at the RBINS notes, “3D printing is increasingly proving to be an extremely useful tool in the field of paleontology, allowing us, for example, to study fossils without damaging the precious originals, and collaborate virtually on the same fossil with colleagues around the world.”

But with some of the mammoth’s bones over two meters in length (bigger than a fully grown adult!), would it be possible to print bones as large as the originals? Coupled with the need to avoid any invasive or potentially damaging work on the original bones, this project presented a unique challenge.

“When the skeleton first came to the museum back in 1869, innovative engineering meant that we didn’t have to drill into, or in any way damage a single bone in order to display the mammoth in its entirety,” explains Dr. Germonpré. “We certainly didn’t want to risk its natural integrity in any way with this new endeavor.”

The question of how to display the new model was also cause for reflection. The original Lier mammoth was supported by several external supports, but the hope was that the new model could rely on an internal, more discrete support structure to really bring the mammoth to life.

Timing would be crucial for the project, as the team wanted the skeleton to be the highlight of the re-opening of Lier’s City Museum. “With just two months to go until the launch date,” adds Project Manager Gertjan Brienen, “every step had to be planned meticulously.”

The solution

3D-printed bones with a custom-built internal frame

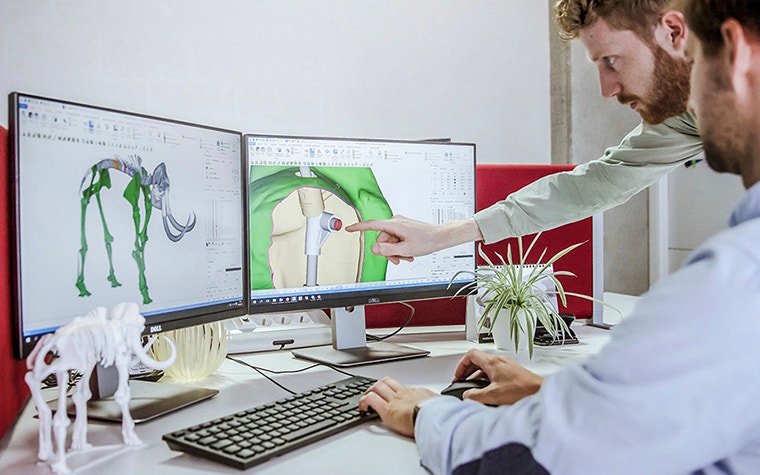

Bringing the Lier mammoth to life would require Materialise’s aptly named Mammoth stereolithography printers, along with what would eventually become a team of 19 people — including engineers, CAD specialists, post-production professionals, and the institute’s own experts including Dr. Germonpré.

“We first introduced our Mammoth stereolithography printers in 2001 to realize projects that require extra-large capacity. With a printer bed dimension of 2100 x 700 x 800mm, they are perfect for ‘single build’ part production,” says Brienen. “At the time, we were thinking of applications such as automotive dashboard prototypes, architectural scale models, bespoke large parts for industrial or manufacturing environments, that kind of thing. But bones? That was a new challenge, one we were honored and excited to take on.”

“The original skeleton was mounted over 150 years ago based on that era’s anatomical knowledge. This was a golden opportunity to virtually adapt the skeleton to match the new insights we now possess.” Dr. Germonpré, Paleontologist at the Royal Belgian Institute of Natural Sciences

But before any printing could happen, dimensional data had to be captured, then optimized for 3D printing. Conveniently, the skeleton’s original external support structure allowed the museum to remove and scan each individual bone in situ, passing the data on to Materialise.

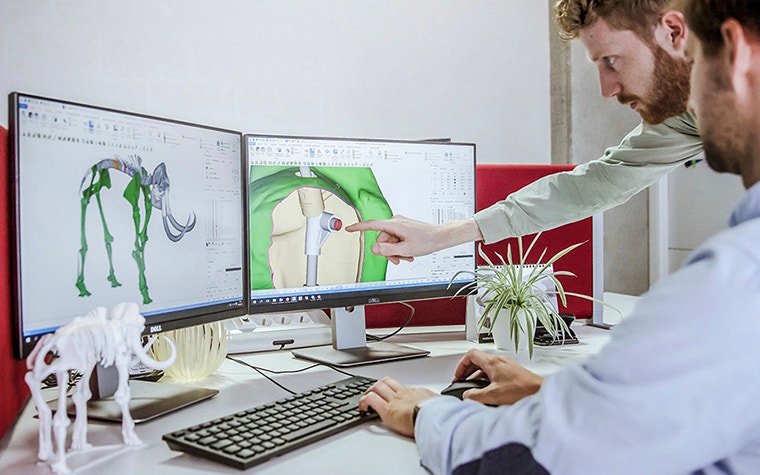

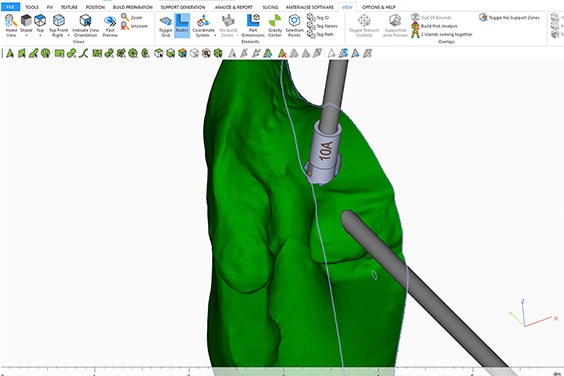

For replicas that would accurately reproduce the original bone dimensions, each scan was cleaned up and optimized specifically for 3D printing using Materialise Magics software, with every single bone digitally orientated over three axes for precise positioning. This allowed the full skeleton to be digitally reconstructed and analyzed in conjunction with Dr. Germonpré and Materialise’s in-house engineers.

“This was a really critical point in the project,” recalls Dr. Germonpré. “It meant we could check consistency against the original skeleton but also apply evolved scientific thinking and discovery. Don’t forget, the original skeleton was mounted over 150 years ago based on that era’s anatomical knowledge. For instance, in the 19th century they assumed the mammoth had a tail as long as that of an elephant, but due to frozen mammoth bodies found in Siberia, we now know that it’s actually shorter. This was a golden opportunity to virtually adapt the skeleton to match the new anatomical insights we now possess.”

3D printing reproduction gave the team the chance to address another issue with the original skeleton: missing bones. “The original Lier mammoth was missing a few bones, including its left tusk,” explains Gertjan Brienen. “On the original, these had been created using sculpted wood. With Materialise 3-matic, we were able to achieve a more precise replica by creating a mirror image of the right tusk. The broken upper jaw was also restored accurately by mirroring the original bone structure.”

“The reconstruction of missing bones and the correction of the original mounting mistakes means that the new, 3D-printed Lier mammoth is actually more scientifically accurate than the original.” Gertjan Brienen, Materialise Project Manager

This digital phase also demanded careful thought regarding the new ‘quasi-invisible’ mount system that would allow the mammoth to appear free-standing. For Gertjan Brienen, this was a key phase.

“Our daughter company, RapidFit, has a lot of experience in using carbon fiber frames for automotive tooling. This was a completely different context but the challenge was the same: to create a relatively lightweight but strong structure. RapidFit helped us to develop a custom, modular carbon frame that would sit predominantly inside the printed skeleton. So we needed the printed bones to exactly replicate their original counterparts, but also accommodate these internal carbon tubes — that would eventually slot together using specially designed, laser sintered connectors — to hold the complete display in place. Our designers met this challenge by integrating entry and exit points that, with pinpoint accuracy, perfectly aligned with the frame requirements.”

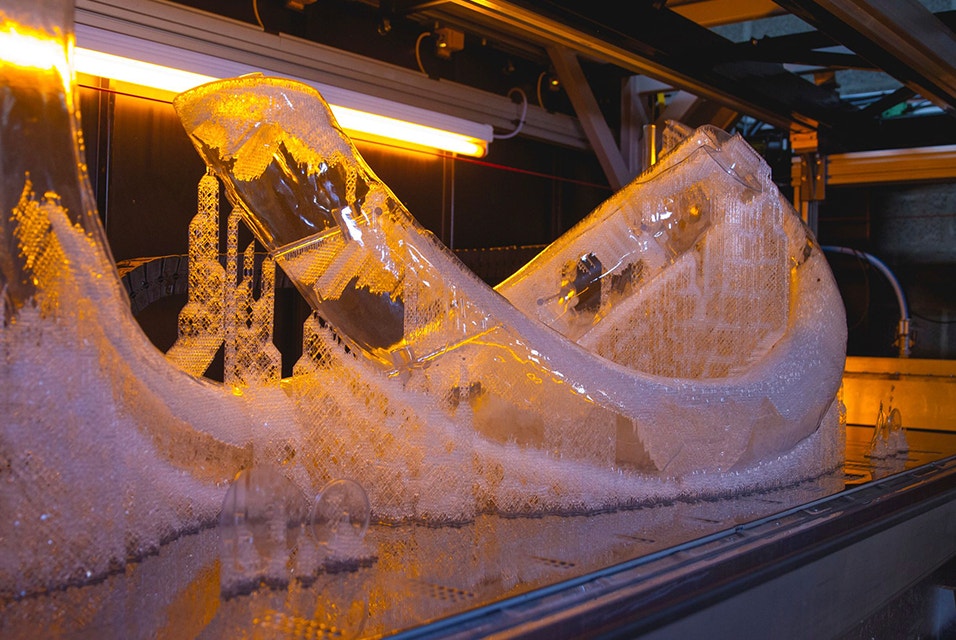

With the design fully ready, printing could start. Materialise’s Mammoth stereolithography machines deposit 1/10th of a millimeter of UV-sensitive liquid resin at a time, hardened selectively by lasers to exactly match build specifications. As well as creating tailored supports to allow scientifically accurate ‘bone shape’ development and laser sintering smaller bones (including the mammoth’s vertebrae) and connection points, the skeleton would take just over 52 days to print, with multiple printers running simultaneously to meet the tight deadline.

Once each new batch of bones was printed, Materialise’s dedicated finishing team took over, employing a combination of paints, textures, and lacquers to match the 3D-printed bones to the original skeleton’s appearance as closely as possible. Eventually, it was time for the new Lier mammoth to assume its final shape.

The result

A highly accurate, realistic mammoth skeleton replica

“During the digital phase of this project, we’d taken every measure to ensure all the bones, the frame, and the 3D-printed polyamide connectors would fit together exactly to form the final mammoth skeleton. But there was only one way to know for sure,” recalls Brienen. “So our finishing team set about assembling the mammoth at our Leuven site. It was quite a spectacle!”

The result was an exact, anatomically correct replica. In fact, thanks to the reconstruction of missing bones and the correction of the original mounting mistakes, “the new, 3D-printed Lier mammoth was actually more scientifically accurate than the original,” explains Gertjan Brienen.

But it was in the wrong place. Brienen continues, “With transportation in mind, we’d designed the bones and frame to essentially break down into six, easier-to-handle assembly units — four legs, the spine/core, and the head. For instance, the spinal section consisted of 30 individual parts connected over the carbon tubes.”

Once the sections arrived at their destination in Lier, Materialise’s finishing team re-assembled the mammoth, back in his original territory and at what will now be his permanent residence.

Brienen concludes, “With a production timeframe of just seven weeks, we’ve created a new piece of history. One that will give generations of visitors a great deal of enjoyment. It utilized all areas of our expertise, from print optimization and design engineering to production and finishing, which makes Materialise such a unique player in the 3D printing industry.

And it was definitely a team effort — we couldn’t have done it without the amazing team of consulting experts and scientists that worked with us. Even though it’s all about preserving the past, this project is the perfect example of the futuristic applications 3D printing has today. And for me, it’s a great feeling to see a customer successfully realize a big idea — literally! — through collaboration with us.”

Share on:

This case study in a few words

Art & design

Materialise Magics

Materialise 3-matic

Stereolithography

Selective laser sintering

TuskXC2700T

Design freedom

Design optimization