3D Printing Services

Taking you from prototyping to small series production.

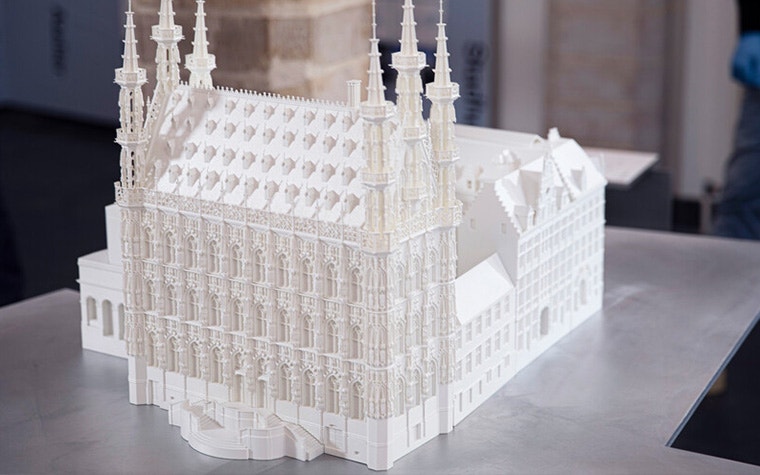

Whether your product is one-of-a-kind or the first of many, you can rely on Materialise Manufacturing. Our 3D printing services offer rapid product development and innovative digital manufacturing, from concept to execution. Call on our industry-leading additive manufacturing (AM) facilities and unmatched experience to fast-track your AM project today.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Industries we work in

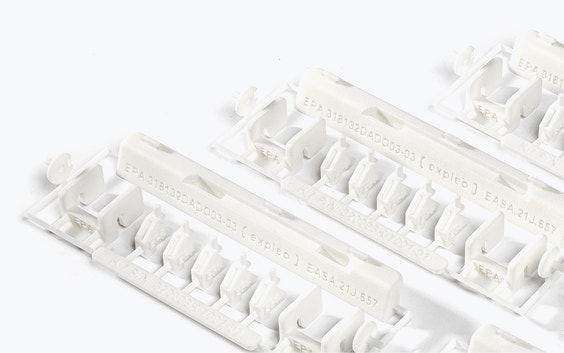

Navigate the future of aerospace with shorter lead times, more affordable small series production, and the unrivaled design freedom that additive manufacturing can offer.

Enter a new era of more sustainable, on-demand manufacturing where creativity and innovation have no boundaries and where quick time-to-market, and zero stock-risk, boost business agility.

Create truly unique solutions, enable mass customization across your product line, move from design to serial production quickly and affordably, and benefit from de-risked and sustainable supply chains.

Why choose Materialise Manufacturing?

A broad range of services, technologies, and materials

When you work with Materialise, you’ll have access to more than Europe’s largest 3D printing factory and an incredible range of technologies, materials, and finishes. You’ll find dedicated manufacturing lines and ready-to-go prototyping services, as well as design for AM experience and consultancy services — all under one roof, and with the simplicity of managing just one supplier.

Quality assurance and control

From our ISO 9001-certified quality management system to our ISO 13485 and EN9100 certifications, we ensure our facilities and processes meet the highest standards. Discover our certifications, our approach to quality assurance and control, and the documentation you can request.

A passion for 3D printing

No one will ever love your project as much as you do — but we’ll be a close second. 3D printing is our passion, which is why we immerse ourselves fully in every step and pay close attention to every detail. We mix global expertise with local support to make you feel at home every time you work with us.

What we know, you’ll know

We believe that knowledge is for sharing. Through the help of a solution-oriented team, you can access everything we’ve learned about 3D printing over the last thirty years to ensure the best outcome for your project.

Applications

Technologies

Materialise believes every designer should be able to create products without limitations. Our 3D printing capacity, comprising the world’s most comprehensive range of technologies, materials, and finishing degrees, offers you unbiased access to the best solution for your project.