Industrial

Whether you’re 3D printing parts, you’d like us to do it for you, or you’re interested in 3D printing consultancy services, we’re there to support you. We offer an extensive platform of software solutions as well as digital manufacturing services based in some of the largest and most complete 3D printing facilities. Discover how we can help you carve your competitive edge.

Our products and services

Call on our industry-leading 3D printing facilities to deliver your prototyping and serial manufacturing part production efficiently — providing the right solution according to your needs and the required quality.

Trust in our powerful, technology-neutral platform of software tools to manage and control your in-house 3D printing processes — offering flexibility, scalability, and sustainability, regardless of the volume in production.

Industries we work in

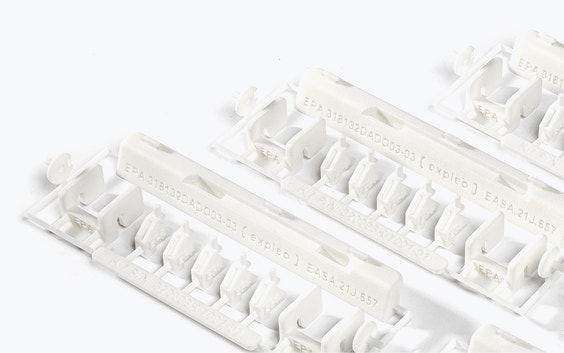

Navigate the future of aerospace with shorter lead times, more affordable small series production, and the unrivaled design freedom that additive manufacturing can offer.

From quick, performant prototypes and visual models to small series manufacturing and automotive tooling, tick every box by bringing 3D printing into existing or new production workflows.

Enter a new era of more sustainable, on-demand manufacturing where creativity and innovation have no boundaries and where quick time-to-market, and zero stock-risk, boost business agility.

No matter the technology or machine, Materialise software manages and optimizes every step of the production process, from request to delivery.

Create truly unique solutions, enable mass customization across your product line, move from design to serial production quickly and affordably, and benefit from de-risked and sustainable supply chains.

Create innovative production tools and prototypes, optimize uptime, and make obsolescence obsolete with 3D-printed spare parts that are never out of date and printed on demand.