Technology

PolyJet

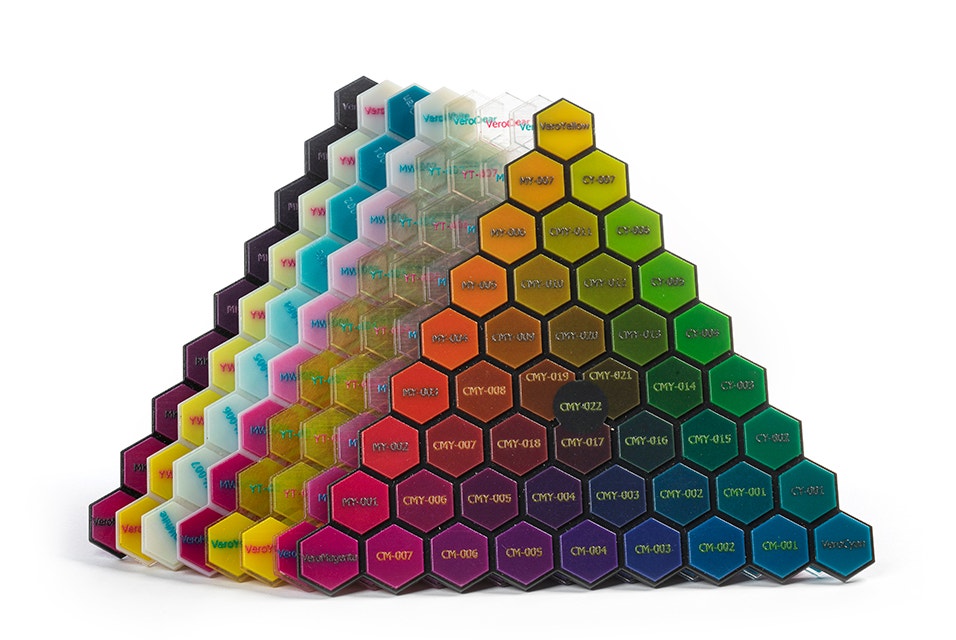

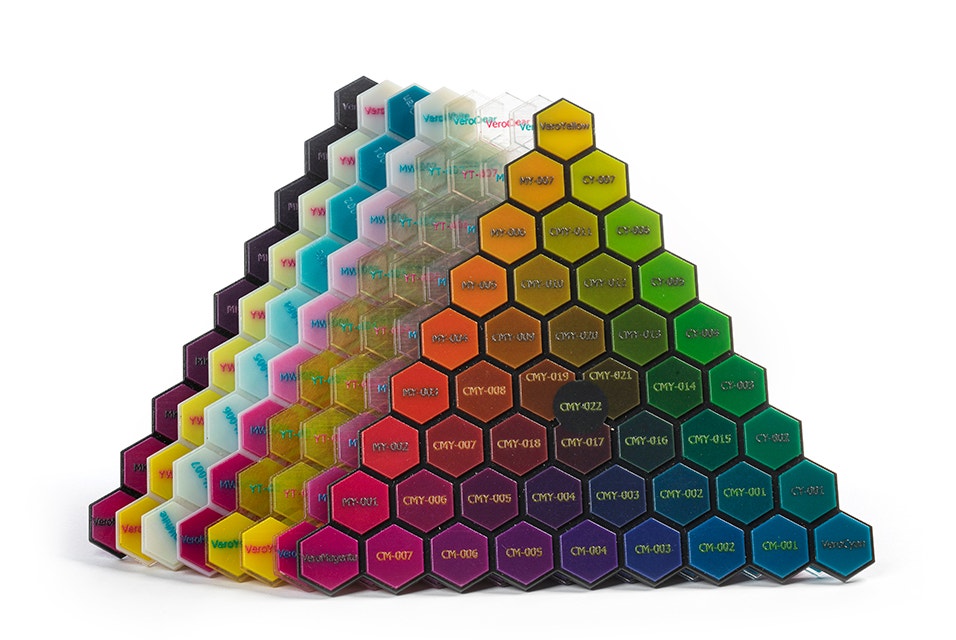

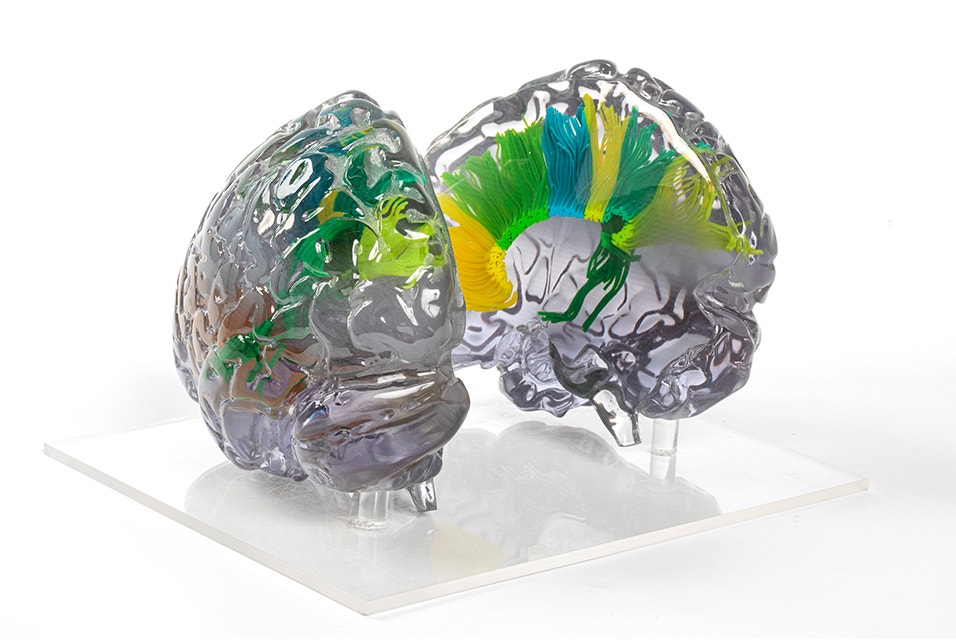

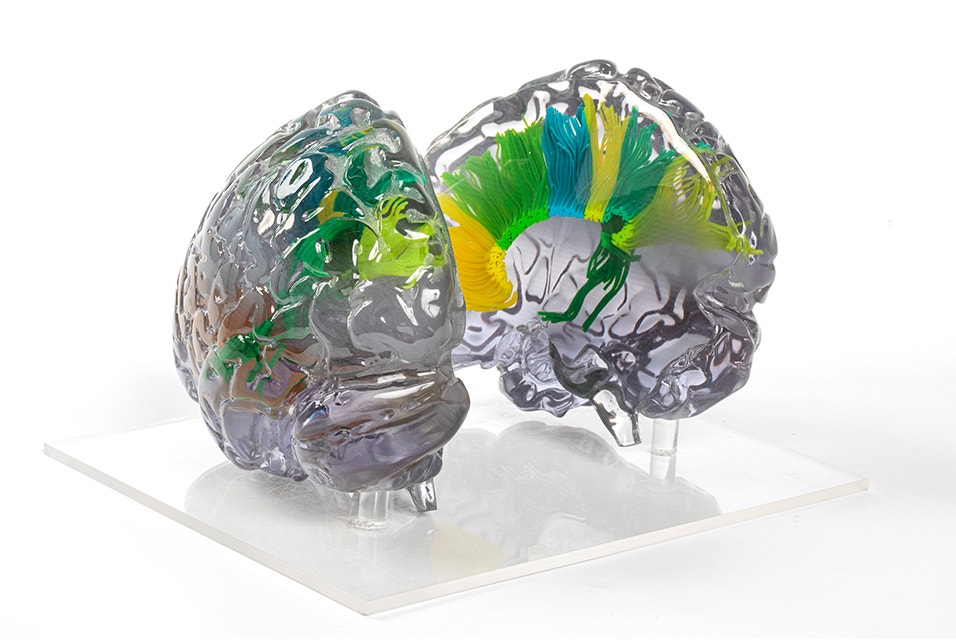

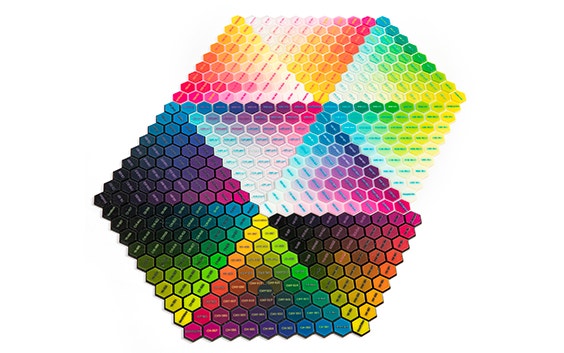

In addition to its high detail and smooth surfaces, PolyJet offers the unique ability to print precision parts and assemblies with multiple materials, all in a single build. A single part can contain different colors, levels of transparency, and diverse physical and mechanical properties, making PolyJet ideal for complex visual models and prototypes.

Why work with Materialise Manufacturing?

When you need to bring a complex idea to life, you can count on Materialise's broad in-house expertise in PolyJet technology to help you develop unique parts that other 3D printing technologies can’t create in one piece. Whether you want to combine different PolyJet materials and colors, or blend materials to achieve specific characteristics, we make sure your end product exceeds your expectations.

Discover applications of PolyJet

Technical specifications

| Maximum build dimensions | Dimensions are unlimited as components may be composed of several sub-parts. The maximum build envelope is 490 x 390 x 200 mm |

| Standard accuracy | 0.1 – 0.3 mm (varies depending on geometry, part orientation, and print size) |

| Layer thickness | 0.032 mm |

| Minimum wall thickness | 1 mm |

| Surface structure | Unfinished parts have a smooth surface, which can be further smoothed through various post-production finishes |

Materials

Choose from a broad selection of materials when you come to Materialise for your PolyJet projects.

Vero

Technology

PolyJet

Description

Vero is a rigid, opaque material that offers excellent detail and can be blended with other PolyJet materials to determine toughness, rigidity, or translucency. Available in multiple colors.

Key characteristics

- Rigid, general-purpose material

- High level of surface detail

- Can be combined with other PolyJet materials to alter toughness, rigidity, or translucency

- Max part dimensions: 490 x 390 x 200 mm

VeroClear

Technology

PolyJet

Description

VeroClear is a rigid, transparent material that offers high dimensional stability and exceptional surface detail. It is ideal for concept modeling and form- and fit-testing of clear parts.

Key characteristics

- Transparent, rigid material

- High level of surface detail

- Can be combined with colored PolyJet materials

- Max part dimensions: 490 x 390 x 200 mm

Agilus

Technology

PolyJet

Description

Agilus is a flexible, rubber-like resin with superior tear-resistance, elongation, and tensile strength. It is ideal for advanced design verification and prototyping of soft-touch components.

Key characteristics

- Flexible, rubber-like material

- Very high elongation at break

- Good tear resistance

- Max part dimensions: 350 x 250 x 100 mm

Composite Materials

Technology

PolyJet

Description

Flexible, rubber-like Agilus is blended with VeroWhite to offer a range of composite materials with pre-defined Shore values and mechanical properties, providing options for a variety of applications.

Key characteristics

- Pre-defined blends of Agilus and VeroWhite

- The addition of VeroWhite influences Agilus' tensile strength and tear resistance

- Different Shore A hardness values are available

- Max part dimensions: 350 x 250 x 100 mm

Work with us: discover our products and services

Want to bring PolyJet into a future project? Discover the services that can help you do it.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.