CUSTOMER STORY

Yuniku: This Eyewear Is Set to Change How You See

The result of extensive co-creation between HOYA Vision Care Company, Materialise, and Hoet Design Studio, Yuniku is the world’s first vision-centric 3D-printed eyewear, designed entirely around your style, comfort and optimal visual experience.

If you wear glasses, you know that finding the right frames can be a challenge. There are many different factors to take into consideration: they have to be the right style, the right color, and of course, a comfortable fit. But did you know that the frames you choose could potentially affect your vision?

The style and fit of your frames determine the angle and size of your lenses and the distance they are set from your eyes, all of which could affect the visual performance of your glasses.

Yuniku offers a completely new approach that results in the best possible end result. How? By combining HOYA’s knowledge of optimal lens design, selection, and positioning, with Hoet’s knowledge of designing stylish frames, and Materialise’s knowledge of 3D printing software, scanning, and engineering.

“Vision-centric eyewear defines the ideal position of the lenses [for] the best visual performance for you. Then the frame is built around the lenses.”

— Felix España, Global NewMedia Manager for Vision Care at HOYA

Yuniku allows for the frames you want, that fit the lenses you need, in the position that allows your eyewear to perform great, look fantastic, and fit like a dream. Felix España, Global NewMedia Manager for Vision Care at HOYA explains, “Vision-centric eyewear defines the ideal position of the lenses in front of the eyes first to provide the best visual performance for you. Then the frame is built around the lenses.”

And that’s not all. Yuniku also transforms your relationship with your optician, as together, you can customize the frames to fit both your aesthetic and visual needs.

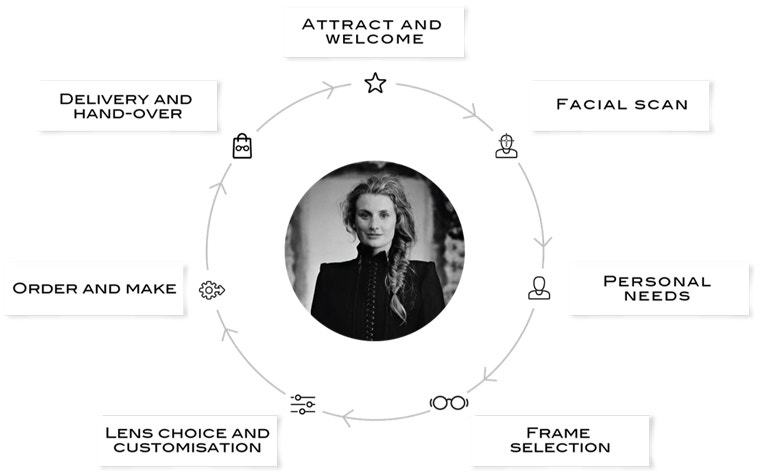

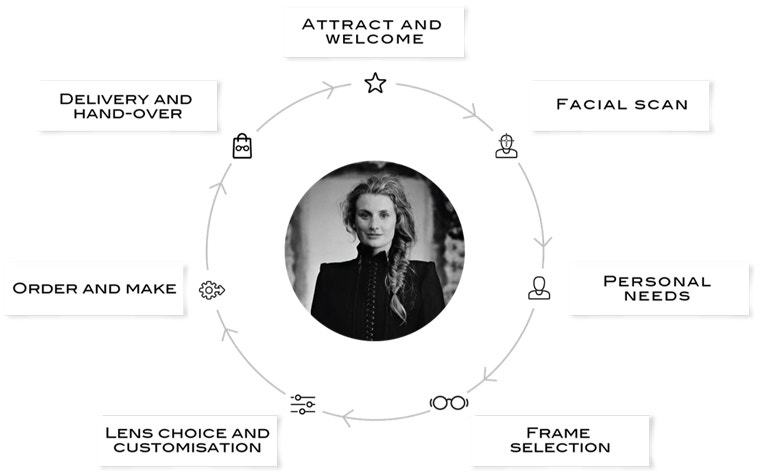

Vision-centric eyewear: the customer experience

The first step of the Yuniku experience is a familiar one, as it starts with viewing and handling a collection of frames to find the design that you like best. However, from that point on, you will be entering a brave new world of exciting possibilities that will forever change how you see eyewear.

“As an eyewear designer, I’m already familiar with how 3D printing can revolutionize this industry. And now with Yuniku, we can share this potential with the world. ”

— Bieke Hoet, Hoet Design Studio

The first step on this new adventure happens when you encounter the Yuniku scanning system, a technology powered by Materialise. What looks like a normal display case, is in fact your key to better vision that looks great.

Once you are standing in position, here is what to expect:

1. Your head is scanned to gather data about the shape of your nose, the position of your ears, and any other features of your facial anatomy and proportions that could affect the comfort and fit of your frames.

2. You complete a short questionnaire about your visual needs and lifestyle — for example, do you wear glasses for work, at home, while playing sports, or only while driving?

3. Advanced software designed by HOYA uses your data to determine the ideal position of the lenses in relation to your eyes and communicates this with Materialise’s software, which in turn tailors the frame around the lenses according to your unique facial characteristics.

4. Finally, together with your optician, you can play with the shape and color of the frames chosen, and customize the design to fit your personal style — turning “I love these glasses, but I wish they were a tiny bit smaller and in green,” into “I love these glasses!!!” – all while the integrated software solutions work to ensure that both ideal lens positioning and fit are preserved.

And this pioneering system isn’t limited to a particular eyewear design brand. By its nature, Yuniku is an open platform that can be implemented across stores for different brands. That means the collection is expected to grow and include frames from several designers, starting first with a base collection by the renowned Belgian brand, Hoet Design Studio.

For Bieke Hoet, Founder of Hoet Design Studio, Yuniku is an opportunity to take high-performance eyewear from a luxury concept into an eye care professional’s reality: “As an eyewear designer, I’m already familiar with how 3D printing can revolutionize this industry. And now with Yuniku, we can share this potential with the world.”

Now for the technical details

Once the virtual design process is finished, a suite of Materialise software is used to make the file ready for 3D printing; from file repair to an automatic orientation on a 3D printing platform. Then your frames enter the certified manufacturing process using laser sintering technology that is dedicated to eyewear in Materialise’s 3D printing facility.

“With HOYA, we have now succeeded in co-creating one of the most sophisticated digital supply chains.”

— Alireza Parandian, Head of Global Strategy for AM Wearables, Materialise

The resulting 3D prints are then turned into consumer-grade products through a multi-step post-production and finishing process we call Materialise Luxura. Finally, your frames are sent to HOYA, where your lenses get assembled, quality controlled, and mounted to ensure they are in the exact position they need to be, ready to reflect your personal style, and more importantly, enhance your vision to a degree never before possible.

“With HOYA, we have now succeeded in co-creating one of the most sophisticated digital supply chains, enabling eye care professionals to deliver enhanced quality of service to their clients,” says Alireza Parandian, Head of Global Strategy for AM Wearables at Materialise (and in-house champion of collaborative innovation).

“At the same time, we have managed to innovate the way eyewear is made — now with lens and frame as one unique product to truly revolutionize the visual experience and comfort for the user. This is our mission: to enable a better and healthier world.”

“With Yuniku, we’re shaping the future of eyewear,” adds Felix at HOYA. “In one word, it’s unique.”

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.