PATIENT STORY

How a 3D-Printed Shoulder Implant Restored a Gunshot Survivor's Mobility and Hope

Just over two years ago, Nathalie Dufaut Danjon was shot by a man with a hunting rifle. The bullet entered her shoulder joint through the front and exited through her shoulder blade. Her shoulder's bony anatomy was destroyed, though the nerves were not affected.

Determined to create something positive out of this experience, instead of focusing on the misery, hatred, and the pain, Nathalie opted to concentrate on the good. She wanted to help others. This is the story of how a 3D-printed shoulder implant gave her back control of her shoulder, and of her life.

Looking for a solution

Nathalie spent more than six months searching for a surgeon who would take her case and help her ease the pain in her shoulder. Of the 12 she saw, none could help her. A traditional implant was not an option because there was too much damage in the shoulder. There was no way to fix it to the bone. After her request for the possibility of a 3D-printed, custom-made prosthesis, she was told, "3D Printing is a gadget, a work in progress. It's not something for you." Frustrated that she could no longer do simple things like make a bed, or hold her children, Nathalie continued her search.

"While there's life, there's hope."

A friend of Nathalie's introduced her to Prof. Narcisse Zwetyenga, the chief of maxillofacial surgery at Centre Hospitalier Universitaire in Dijon, France. Wondering how a maxillofacial surgeon could help out with her shoulder problem, Nathalie went to see him. To her surprise and relief, Prof. Zwetyenga said something could be done. This first positive response finally gave Nathalie hope. Prof. Zwetyenga introduced her to Dr. Brice Viard, an orthopaedic surgeon in his team.

Taking on advanced joint destruction

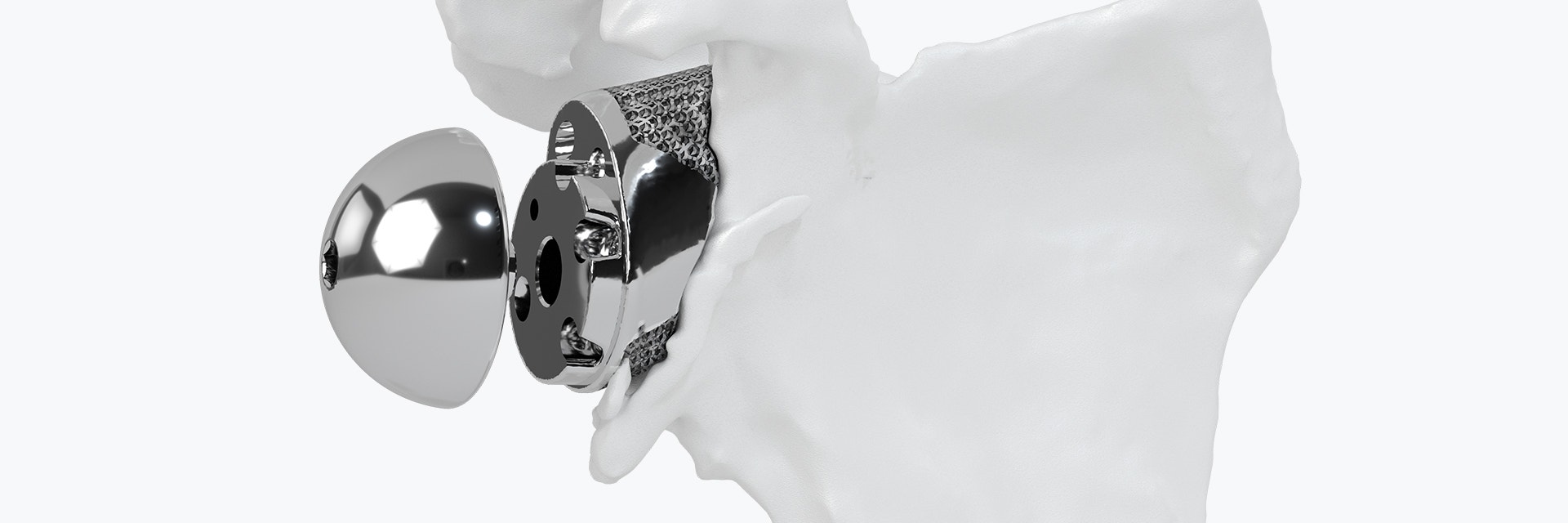

Dr. Viard saw he was faced with a very particular case of advanced joint destruction that was difficult to treat with current practices. The lesions in the shoulder were very advanced, he says. "The patient's humerus had no proximal articular surface and was severely deformed," he explains. The 3D image also outlined the loose bone fragments that were sticking to the inner side of the deltoid muscle and stuck in a fibrous membrane.

Dr. Viard explains further that the most difficult part was the advanced destruction of the glenoid. "As standard implants are designed for the standard population," he says, "special cases like this one don't leave room for good reconstruction. It was impossible to obtain osseous fixation on the scapula."

Where there's a will, there's a way

Dr. Brice Viard says that his collaboration with Materialise helped him a lot, especially during the preoperative planning. "The contact with the engineers was very hands on and we could work step by step to create an implant that was realistic for this specific surgery."

"You can see how the implants are positioned after the reconstruction," he says as he shows the on-screen X-ray. "They're both on the humeral and on the glenoid sides," he says. "It's a reverse shoulder prosthesis."

Very satisfactory results

Today, the patient is doing really well, he says. It's been almost a year since the surgery and she has regained very satisfactory articular mobility. She's very happy with the results. It's still a little early to ascertain the bone ingrowth in the implant, he continues, but short and mid-term results are very satisfactory. “This creates reconstruction possibilities for the future, with better conditions and better results,” Dr. Viard says. Nathalie’s life-changing surgery offers hope to other patients with complex surgical needs. In doing so it dispels the myth that 3D printing in medicine is “a gadget.”

The Materialise Glenius Glenoid Reconstruction System is not commercially available in the US and Canada.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.